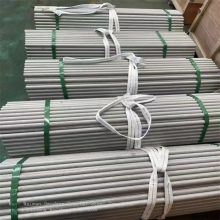

Nickel 200 201 Uns N02200 N02201 Sheets Plates Nickel-based Alloy Pipe Manufacturer

Product Overview

Our Nickel 200 and 201 (UNS N02200 and N02201) sheets, plates, and strips are premium - quality products crafted by a professional manufacturer. These nickel - based precision alloys are renowned for their excellent performance in a wide range of applications, from chemical processing to electronic components.

Composition and Properties

Composition: Nickel 200 and 201 are high - purity wrought nickel alloys. Nickel 200 contains a minimum of 99.0% nickel, along with small amounts of other elements such as iron, carbon, manganese, silicon, and copper. Nickel 201 has a lower carbon content compared to Nickel 200, which makes it more suitable for applications where resistance to graphitization and embrittlement at high temperatures is required.

Corrosion Resistance: These alloys offer outstanding resistance to corrosion in many environments, including neutral and alkaline salt solutions, reducing and oxidizing acids (under specific conditions), and dry gases such as oxygen, hydrogen, and ammonia. This corrosion resistance makes them ideal for use in chemical storage tanks, piping systems, and marine applications.

Thermal and Electrical Conductivity: Nickel 200 and 201 have good thermal and electrical conductivity. Their electrical conductivity is comparable to that of copper in some cases, which is why they are often used in electrical and electronic components such as battery electrodes, connectors, and resistors. The high thermal conductivity also allows for efficient heat transfer in heat exchangers and other thermal management applications.

Mechanical Properties: They possess excellent mechanical properties over a wide temperature range. At room temperature, these alloys have high strength and good ductility, which means they can be easily formed, machined, and welded. They also maintain their mechanical integrity at elevated temperatures, making them suitable for high - temperature applications such as furnace components and aerospace parts.

Surface Treatment

The sheets, plates, and strips undergo a polishing surface treatment. This not only gives them an aesthetically pleasing silver - colored finish but also provides several functional benefits. The polished surface reduces friction, which is beneficial in applications where parts need to slide or move against each other. It also helps in preventing the accumulation of dirt and contaminants, making the products easier to clean and maintain. Additionally, the smooth surface can enhance the corrosion resistance of the alloys by reducing the number of surface irregularities where corrosion could potentially start.

Customization

One of the key advantages of our products is the ability to customize according to the blueprint. Whether you need a specific shape, size, or thickness for your project, our experienced manufacturing team can meet your requirements. We use advanced manufacturing techniques and equipment to ensure that the final products precisely match your design specifications. This customization option is particularly valuable for customers in industries such as aerospace, automotive, and specialized machinery, where unique components are often needed.

Applications

Chemical Industry: Due to their corrosion resistance, Nickel 200 and 201 sheets, plates, and strips are widely used in the chemical industry. They are used to construct reactors, storage tanks, and piping systems for handling various chemicals, including caustic soda, hydrochloric acid, and sulfuric acid.

Electrical and Electronics: Their excellent electrical conductivity makes them a popular choice for electrical and electronic applications. They are used in battery electrodes, where they can improve the performance and lifespan of the battery. They are also used in electrical connectors, switches, and resistors.

Aerospace and Aviation: In the aerospace and aviation industries, the high - temperature strength and corrosion resistance of these alloys are highly valued. They are used in engine components, airframe structures, and fuel systems, where reliability and performance under extreme conditions are crucial.

Food Processing: The non - toxic nature of nickel and its alloys makes them suitable for food processing applications. They are used in equipment such as food storage containers, mixing bowls, and processing machinery, where hygiene and corrosion resistance are essential.

Quality Assurance

We are committed to providing high - quality products. Our manufacturing process adheres to strict quality control standards. We conduct a series of tests on the raw materials and the finished products, including chemical composition analysis, mechanical property testing, and non - destructive testing. This ensures that every sheet, plate, and strip that leaves our factory meets or exceeds the industry standards and your specific requirements.

Global Reach

Our products are exported to a wide range of markets, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid - East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, and South Asia. Our company, established in 2017, has an export share of US$5 Million - US$10 Million. With a team of 11 - 20 experienced sales representatives, we are dedicated to providing excellent customer service and technical support to our international clients.

In conclusion, our Nickel 200 and 201 sheets, plates, and strips are a reliable choice for a variety of industries. Their superior properties, customizable options, and high - quality manufacturing make them stand out in the global market.

Send Inquiry to This Supplier

You May Also Like

-

High Corrosion Resistant Uns N02200 Seamless Tube for Chemical EquipmentNegotiableMOQ: 1 Ton

-

Nickel 200 Uns N02200 Corrosion Resistant Pure Nickel Seamless PipeNegotiableMOQ: 1 Ton

-

Grade N02200 Nickel Pipe for High Performance in Challenging ConditionsNegotiableMOQ: 1 Ton

-

ASME Sb163 N02200 Alloy 200 Nickel Alloy Seamless Tube for Heat ExchangerNegotiableMOQ: 1 Ton

-

High Quality Nickel Pipe Manufacturer Uns N02201/Uns N02200 Pure Nickel Seamless PipeNegotiableMOQ: 1 Ton

-

Nickel 201 Alloy Steel Seamless Pipe/Tube ASTM B444 201/Uns N02201NegotiableMOQ: 1 Ton

-

Nickel-based Alloy Pipe Monel 400 /Monel K500 Superalloy TubeNegotiableMOQ: 10 Kilograms

-

UNS N06455 Nickel Alloy Seamless Pipe ASTM B619 Capillary Precision Nickel Alloy TubeNegotiableMOQ: 1 Kilogram

-

UNS N06022 Welded Nickel Alloy Tube ASTM B622 Capillary Precision Welded PipeNegotiableMOQ: 1 Kilogram

-

ASTM B619 B622 Standard Customizable Inch Tube Astelloy C276 Hastelloy C22 Hastelloy C-2000 Hastelloy C-4 for SaleNegotiableMOQ: 10 Kilograms