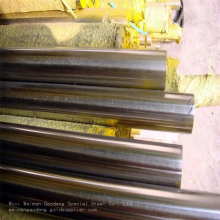

Hastelloy C-276 Hastelloy C-59 New Best Selling Cheap Convenient High Toughness

Product Overview

Our Hastelloy C - 276 and Hastelloy C - 59 are revolutionary products in the field of high - performance alloys. These nickel - based alloys are designed to meet the most demanding industrial requirements, offering a unique combination of corrosion resistance, high toughness, and cost - effectiveness. Whether you are in the aviation, electronics, industrial, medical, or chemical sectors, our Hastelloy alloys are the ideal choice for your projects.

Composition and Structure

- Hastelloy C - 276: This alloy is a nickel - molybdenum - chromium - tungsten alloy. The high nickel content provides excellent resistance to a wide range of corrosive media. Molybdenum enhances the alloy's resistance to pitting and crevice corrosion, while chromium improves its resistance to oxidizing environments. Tungsten further strengthens the alloy's overall performance, making it suitable for highly aggressive chemical environments.

- Hastelloy C - 59: It is a nickel - chromium - molybdenum alloy. The chromium content in Hastelloy C - 59 is relatively high, which gives it outstanding resistance to oxidizing acids and high - temperature corrosion. The molybdenum content also contributes to its excellent resistance to reducing acids and localized corrosion. The well - balanced composition of these elements results in a microstructure that is both strong and ductile.

Key Features

- Corrosion Resistance: Both Hastelloy C - 276 and Hastelloy C - 59 offer exceptional corrosion resistance in various environments. They can withstand the attack of strong acids such as sulfuric acid, hydrochloric acid, and phosphoric acid. In addition, they are highly resistant to stress - corrosion cracking, making them suitable for applications where the material is exposed to corrosive substances under stress.

- High Toughness: These alloys possess high toughness, which means they can absorb a large amount of energy before fracturing. This property is crucial in applications where the material may be subjected to impact or cyclic loading, such as in aviation components or industrial machinery.

- Cost - Effectiveness: Despite their high performance, our Hastelloy alloys are competitively priced. Their long - term durability and low maintenance requirements result in significant cost savings over the life of the product. This makes them an economical choice for businesses looking to balance quality and cost.

- Convenience: Our Hastelloy products are available in various forms, including bars, pipes, and sheets. We can also customize the products according to your specific requirements. This flexibility allows you to easily integrate our alloys into your existing production processes.

Applications

- Aviation Industry: In the aviation sector, the high strength - to - weight ratio and corrosion resistance of Hastelloy C - 276 and Hastelloy C - 59 make them suitable for use in aircraft engines, landing gear components, and other critical parts. They can withstand the harsh conditions of high - altitude flight and exposure to various chemicals.

- Electronics Industry: The excellent electrical conductivity and corrosion resistance of these alloys are beneficial for electronic components. They can be used in circuit boards, connectors, and other parts that require reliable performance in a potentially corrosive environment.

- Industrial Applications: In industrial settings, Hastelloy alloys are used in chemical processing plants, power generation facilities, and oil and gas refineries. They can handle the extreme conditions of high - temperature and high - pressure processes, as well as the presence of corrosive chemicals.

- Medical Field: The biocompatibility and corrosion resistance of these alloys make them suitable for medical applications. They can be used in surgical instruments, implants, and medical devices, ensuring the safety and reliability of medical treatments.

- Chemical Industry: Due to their outstanding corrosion resistance, Hastelloy C - 276 and Hastelloy C - 59 are widely used in the chemical industry. They can be used in storage tanks, reaction vessels, and piping systems for handling a variety of corrosive chemicals.

Quality Assurance

We are a professional manufacturer established in 2017. Our company, with a team of 11 - 20 experienced salespeople, has an annual export share ranging from US$5 million to US$10 million. Our products comply with the ASTM/ASME standards, ensuring the highest quality and performance. We conduct strict quality control measures throughout the production process, from raw material inspection to finished product testing. This guarantees that every piece of our Hastelloy C - 276 and Hastelloy C - 59 products meets or exceeds your expectations.

Global Reach

Our main markets cover North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market. This wide - reaching market presence demonstrates the trust and recognition that our products have gained globally. Whether you are a large - scale enterprise or a small - and - medium - sized business, we can provide you with high - quality Hastelloy alloys and excellent customer service.

Send Inquiry to This Supplier

You May Also Like

-

High Temperature No Corrosion Alloy Bar Nimonic80A/Nimonic81 Nickel BarsNegotiableMOQ: 10 Kilograms

-

High Quality High Temperature Nickel Plate Special Alloy Nimonic 75 90 80a 115 Round Bar & RodNegotiableMOQ: 10 Kilograms

-

Hot Sale Guaranteed Quality Stock Nickel Silver Alloy Bar Nichrome Grade N07080 for Industrial ApplicationsNegotiableMOQ: 10 Kilograms

-

Factory Price Nimonic86 Nimonic90 100mm Annealed Pickled Nickel Alloy Round Bar for Inductors and WiresNegotiableMOQ: 10 Kilograms

-

High Temperature Alloy Ncf750/Nimonic263 Nickel Alloy Steel Pipe Polished Alloy PipeNegotiableMOQ: 10 Kilograms

-

Nimonic 115 Nimonic 901 High Precision Nickel StripNegotiableMOQ: 10 Kilograms

-

High Temperature Alloy Nimonic 901 Plates/Sheets/Coils/StripsNegotiableMOQ: 10 Kilograms

-

Special Alloy Steel NIMONIC Alloy901 N09901 Superalloy PlateNegotiableMOQ: 10 Kilograms

-

Nimonic Alloy 90 UNS N07090 Nimonic 90 Sheet Plate for Turbine Disk BladeNegotiableMOQ: 10 Kilograms

-

Nickel Alloy Nimonic115 High-Temperature Alloys Strip Foil Mill Direct SalesNegotiableMOQ: 10 Kilograms