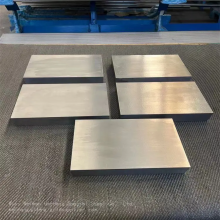

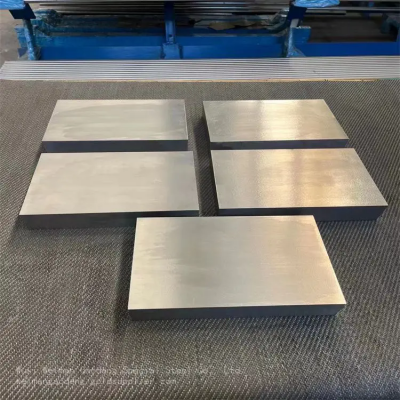

Nimonic Alloy 90 UNS N07090 Nimonic 90 Sheet Plate for Turbine Disk Blade

Product Overview

Our Nimonic Alloy 90 (UNS N07090) sheet plate is a high - performance material specifically designed for turbine disk blade applications. Nimonic 90 is a nickel - based alloy renowned for its exceptional mechanical properties and resistance to high - temperature environments, making it an ideal choice for the demanding conditions within turbines.

Chemical Composition

The chemical composition of Nimonic Alloy 90 is precisely engineered to deliver outstanding performance. It has a high nickel content, typically around 54%, which provides excellent corrosion resistance and serves as a stable base for the alloy. Chromium, present in the range of 18 - 21%, enhances the alloy's oxidation resistance at elevated temperatures. Cobalt, with a proportion of 15 - 21%, contributes to the alloy's high - temperature strength and creep resistance. Additionally, small amounts of titanium, aluminum, and carbon are added to improve precipitation hardening, which further enhances the mechanical properties of the material.

Physical and Mechanical Properties

- Density: The density of Nimonic 90 is approximately 8.2 g/cm³. This relatively high density is a characteristic of nickel - based alloys and is related to its high - strength properties.

- Melting Point: It has a melting point in the range of 1320 - 1370°C. This high melting point allows the material to maintain its integrity in the extremely hot environments of turbine engines.

- Tensile Strength: At room temperature, Nimonic 90 can achieve a tensile strength of up to 1200 MPa. Even at high temperatures, such as 800°C, it can still maintain a tensile strength of around 500 MPa, ensuring reliable performance under stress.

- Yield Strength: The yield strength at room temperature is typically around 700 MPa, and it remains relatively high at elevated temperatures, providing excellent resistance to plastic deformation.

Manufacturing and Quality Assurance

Our Nimonic 90 sheet plates are manufactured using advanced production techniques. We start with high - quality raw materials that are carefully selected to meet strict chemical composition requirements. The alloy is then melted in state - of - the - art furnaces, followed by precision rolling processes to achieve the desired thickness and surface finish of the sheet plates.

Throughout the manufacturing process, we implement a comprehensive quality control system. Each batch of sheet plates undergoes rigorous testing, including chemical analysis, mechanical property testing, and non - destructive testing such as ultrasonic testing and eddy - current testing. This ensures that every product meets the ASTM/ASME standards, guaranteeing its reliability and performance.

Applications

- Aviation Industry: In the aviation sector, turbine engines operate at extremely high temperatures and under high - stress conditions. Our Nimonic 90 sheet plates are used to manufacture turbine disk blades, which are critical components in aircraft engines. The alloy's high - temperature strength and oxidation resistance ensure the safety and reliability of the engines during flight.

- Power Generation: In power plants, gas turbines are used to generate electricity. The harsh operating conditions in these turbines require materials that can withstand high temperatures and mechanical stress. Nimonic 90 sheet plates are an excellent choice for turbine disk blades in these power - generation applications, helping to improve the efficiency and longevity of the turbines.

- Industrial Applications: Some industrial processes involve high - temperature operations, such as in chemical and petrochemical plants. The corrosion resistance and high - temperature strength of Nimonic 90 make it suitable for use in various industrial equipment components, including those in high - temperature furnaces and reactors.

Packaging and Shipping

We understand the importance of proper packaging to ensure the safe transportation of our products. Our Nimonic 90 sheet plates are carefully packed in wooden crates or steel pallets to prevent damage during handling and shipping. We offer flexible shipping options, including sea freight and air freight, to meet the diverse needs of our international customers. Whether you are located in North America, South America, Europe, Asia, or other regions, we can ensure that your order is delivered in a timely and secure manner.

After - Sales Service

We are committed to providing excellent after - sales service. Our team of experienced technical experts is available to offer technical support and advice on the use and application of our Nimonic 90 sheet plates. If you encounter any issues or have any questions regarding our products, we will respond promptly and work with you to find the best solutions. We also welcome feedback from our customers, which helps us continuously improve our products and services.

Send Inquiry to This Supplier

You May Also Like

-

Factory Direct Sales Corrosion Resistance N10276 N06985 Nickel Alloy Hastelloy C-276 Sheet PlateNegotiableMOQ: 10 Kilograms

-

Premium Hastelloy C-2000 Nickel Alloy for Industrial ApplicationsNegotiableMOQ: 10 Kilograms

-

High Quality Customized Hatelloy Alloy Factory Supply Super Nikel Bar Hastelloy C-4NegotiableMOQ: 10 Kilograms

-

Hot Selling Black Bright Surface Hastelloy C-276 Steel Bar Kawat Las Hastelloy C276NegotiableMOQ: 10 Kilograms

-

Hastelloy C-4 Plate Price/Hastelloy B-2 Steel Plate/ Hastelloy B-3manufacturerNegotiableMOQ: 10 Kilograms

-

High Temperature Hastelloy C-276 Uns N10276 W. Nr. 2.4819 Nickel Alloy Rod and Bar ManufactureNegotiableMOQ: 10 Kilograms

-

Nickel Strip Sheet Plate Rod Round Bar Hastelloy C-276 C22 Nickel Bar Hastelloy C276 No10276NegotiableMOQ: 10 Kilograms

-

Hastelloy C-276 Hastelloy C-59 New Best Selling Cheap Convenient High ToughnessNegotiableMOQ: 10 Kilograms

-

Premium Quality HastelloyC-276 Nickel Alloy Round Bar/Rod,Factory Direct SalesNegotiableMOQ: 10 Kilograms

-

Nitronic 50 Stainless Steel Round Bar XM-19 Bright Round Bar Dia.50NegotiableMOQ: 10 Kilograms