High Temperature No Corrosion Alloy Bar Nimonic80A/Nimonic81 Nickel Bars

High Temperature No Corrosion Alloy Bar Nimonic80A/Nimonic81 Nickel Bars

Introduction

Our High Temperature No Corrosion Alloy Bar, specifically the Nimonic80A and Nimonic81 Nickel Bars, are a remarkable solution for various industries that demand high - performance materials. These nickel bars are crafted with precision to meet the most stringent requirements in challenging environments.

Product Composition

The Nimonic80A and Nimonic81 nickel bars are primarily composed of nickel alloy powder. Nickel is the base metal, which provides excellent ductility and corrosion resistance. The alloying elements are carefully selected and proportioned to enhance the overall performance of the bars. These alloys adhere to the ASTM/ASME standards, ensuring high - quality and reliable products. The strict compliance with these standards means that our bars can be used in applications where safety and performance are of utmost importance.

Key Features

- High - Temperature Resistance: One of the most outstanding features of these nickel bars is their ability to withstand extremely high temperatures. In high - heat environments such as those found in aviation engines, they can maintain their structural integrity and mechanical properties. This high - temperature stability allows for continuous operation in harsh thermal conditions without significant degradation, reducing the risk of component failure and ensuring long - term reliability.

- Corrosion Resistance: The bars are highly resistant to corrosion. They can endure exposure to various corrosive substances, including chemicals in the chemical industry and moisture in the medical and electronics fields. This corrosion resistance is crucial as it extends the service life of the components made from these bars, reduces maintenance costs, and ensures the safety and functionality of the equipment.

- Mechanical Strength: With excellent mechanical strength, the Nimonic80A and Nimonic81 nickel bars can handle heavy loads and stresses. Whether it is in industrial machinery or aviation structures, they can provide reliable support. Their high tensile strength and good fatigue resistance make them suitable for applications that require long - term, repetitive use.

Applications

- Aviation: In the aviation industry, these nickel bars are used in critical components such as turbine blades, engine parts, and structural elements. The high - temperature and corrosion - resistant properties ensure the safety and efficiency of aircraft engines, which operate under extreme conditions.

- Electronics: In the electronics field, the bars can be used in high - precision components. Their corrosion resistance protects the sensitive electronic circuits from damage, and their high - temperature stability ensures the proper functioning of electronic devices even in hot environments.

- Industrial: For industrial applications, these bars are used in manufacturing equipment, such as high - temperature furnaces and chemical processing plants. They can withstand the harsh industrial environment and contribute to the smooth operation of industrial processes.

- Medical: In the medical industry, the corrosion - resistant nature of the bars makes them suitable for medical devices. They can be used in surgical instruments and implantable devices, where cleanliness and long - term durability are essential.

- Chemical: In the chemical industry, the bars are used in reactors, pipelines, and other equipment. Their resistance to various chemicals ensures the safety and efficiency of chemical production processes.

Manufacturing and Quality Assurance

We, as a manufacturer established in 2017, have a team of 11 - 20 professional sales representatives. Our company, located at No. 168 Qiangao Road, has an annual export share ranging from US$5 Million - US$10 Million, with our products being sold to major markets across the globe, including North America, South America, Europe, Asia, Africa, and Oceania.

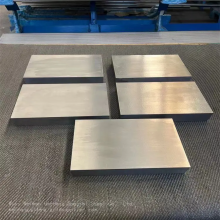

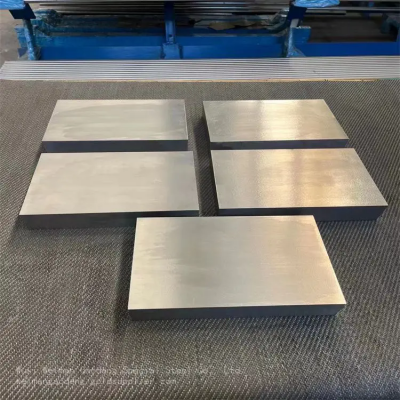

We implement strict quality control measures throughout the manufacturing process. From the selection of raw materials to the final inspection of the finished products, every step is carefully monitored. Our production process is designed to ensure that each Nimonic80A and Nimonic81 nickel bar meets or exceeds the ASTM/ASME standards. We use advanced manufacturing techniques to achieve precise dimensions and excellent surface finishes, which further enhance the performance and usability of the bars.

Technical Specifications

- Dimensions: We offer a wide range of dimensions to meet different customer requirements. The diameter and length of the bars can be customized according to specific application needs.

- Surface Finish: The bars have a smooth surface finish, which not only improves their aesthetic appearance but also reduces the risk of corrosion and wear. The smooth surface also facilitates the assembly and installation of components made from these bars.

- Tolerance: Our manufacturing process ensures tight tolerances, which means that the actual dimensions of the bars are very close to the specified values. This high level of precision is essential for applications where accurate fitting and performance are required.

In conclusion, our High Temperature No Corrosion Alloy Bar, Nimonic80A and Nimonic81 Nickel Bars, are a top - choice for industries that need high - performance materials. With their excellent properties, wide range of applications, and strict quality control, they can provide reliable solutions for your most challenging projects.

Send Inquiry to This Supplier

You May Also Like

-

High Temperature Alloy Nimonic 901 Plates/Sheets/Coils/StripsNegotiableMOQ: 10 Kilograms

-

Special Alloy Steel NIMONIC Alloy901 N09901 Superalloy PlateNegotiableMOQ: 10 Kilograms

-

Nimonic Alloy 90 UNS N07090 Nimonic 90 Sheet Plate for Turbine Disk BladeNegotiableMOQ: 10 Kilograms

-

Nickel Alloy Nimonic115 High-Temperature Alloys Strip Foil Mill Direct SalesNegotiableMOQ: 10 Kilograms

-

Hot Rolled High Temperature Nimonic Alloy 90 Uns N07080 Nickel Alloy Plate/Sheet AlloyNegotiableMOQ: 10 Kilograms

-

Hastelloy C-276 Nickel Wire With High Quality in Competitive PriceNegotiableMOQ: 10 Kilograms

-

ASTM Hastelloy Alloy Bar Hastelloy C-22 Uns N06022 C276 Excellent Corrosion ResistanceNegotiableMOQ: 10 Kilograms

-

Hastelloyc-276 Is a Corrosion-Resistant N10276 Nickel-Based Alloy Stainless Steel PlateNegotiableMOQ: 10 Kilograms

-

Factory Direct Sales Corrosion Resistance N10276 N06985 Nickel Alloy Hastelloy C-276 Sheet PlateNegotiableMOQ: 10 Kilograms

-

Premium Hastelloy C-2000 Nickel Alloy for Industrial ApplicationsNegotiableMOQ: 10 Kilograms