China Manufacturers High Quality Astm Gr2 Gr1 Gr5 Gr7 Gr12 Gr16 Titanium Bar / Rod

China Manufacturers High Quality Astm Gr2 Gr1 Gr5 Gr7 Gr12 Gr16 Titanium Bar / Rod

Product Overview

Our titanium bars/rods are proudly manufactured in China, adhering to the highest quality standards. They are available in multiple grades including Gr1, Gr2, Gr5, Gr7, Gr12, and Gr16, each offering unique properties to meet diverse industrial needs. These bars are forged using advanced techniques, ensuring excellent mechanical performance and durability.

Physical Characteristics

Shape

The bars come in a round shape, which is a classic and widely used form in industrial applications. The round shape provides uniform stress distribution, making them suitable for various load - bearing scenarios. It also allows for easy machining and integration into different manufacturing processes.

Grade - Specific Properties

- Gr1 and Gr2: These are commercially pure titanium grades. They offer excellent corrosion resistance, especially in highly oxidizing environments. They are also known for their good formability, making them ideal for applications where complex shapes need to be formed. For example, they can be used in the production of chemical processing equipment, such as heat exchangers and storage tanks.

- Gr5: This is one of the most popular titanium alloys, also known as Ti - 6Al - 4V. It combines high strength with good ductility. Gr5 titanium bars are commonly used in aerospace applications, such as aircraft frames and engine components, due to their ability to withstand high - stress conditions and extreme temperatures.

- Gr7: It has similar corrosion - resistant properties to Gr2 but with enhanced resistance to crevice corrosion. This makes it a great choice for applications in marine environments, like offshore oil and gas platforms, where exposure to saltwater can cause significant corrosion.

- Gr12: It offers a combination of strength and corrosion resistance. Gr12 titanium bars are often used in the petrochemical industry, particularly in equipment handling sulfur - containing compounds, as they can resist the corrosive effects of these substances.

- Gr16: This grade has a lower oxygen content compared to some other grades, which results in better ductility and formability. It can be used in applications where cold - working processes are involved, such as in the production of fasteners.

Manufacturing Technique

The titanium bars are produced using the forging technique. Forging involves shaping the metal by applying compressive forces, which helps to refine the grain structure of the titanium. This results in improved mechanical properties such as higher strength, better toughness, and enhanced fatigue resistance. The forging process also allows for better control over the dimensions and quality of the bars, ensuring consistent performance across the entire production batch.

Application Areas

Industrial Use

These titanium bars are primarily designed for industrial applications. In the chemical industry, they are used in the construction of reactors, pipes, and valves due to their corrosion resistance. In the automotive industry, they can be used in high - performance engine parts to reduce weight and improve fuel efficiency. The aerospace sector also benefits greatly from these bars, as they help in building lightweight yet strong components for aircraft and spacecraft. Additionally, in the medical field, titanium bars are used in the production of implants due to their biocompatibility.

Company Background

We are a professional manufacturer, Wuxi Weiman Gaodeng Special Steel Co., Ltd., established in 2017. Our company specializes in the production of stainless steel, alloy steel pipes, nickel - based alloys, and titanium alloys. With an export share ranging from US$5 Million - US$10 Million, we have a well - established international market presence. Our team consists of 11 - 20 experienced sales representatives who are dedicated to providing excellent customer service. Our products are sold in major markets around the world, including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as the domestic market.

Quality Assurance

We implement strict quality control measures throughout the production process. From the selection of raw materials to the final inspection of the finished products, every step is carefully monitored to ensure that our titanium bars meet or exceed international quality standards. Our products are tested for mechanical properties, chemical composition, and dimensional accuracy to guarantee their reliability and performance.

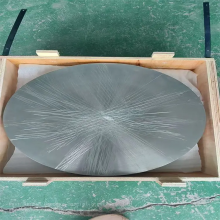

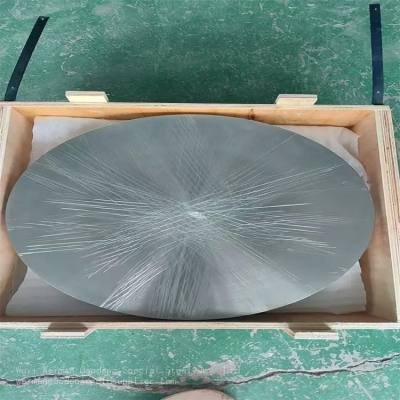

Packaging and Shipping

Our titanium bars are carefully packaged to prevent damage during transportation. They are typically wrapped in protective materials and placed in sturdy containers. We work with reliable shipping partners to ensure timely and safe delivery of our products to customers around the world. Whether it is a small order or a large - scale shipment, we are committed to providing efficient and cost - effective shipping solutions.

Send Inquiry to This Supplier

You May Also Like

-

Cut to Size Titanium Rod High Pure Industrial GR1 GR2 Metal Price Per kg GR5 Ti-6Al-4V Titanium Alloy Round BarNegotiableMOQ: 1 Ton

-

Gr2 Titanium Sheet Gr5 Titanium Plate for Medical Customized Titanium PlateNegotiableMOQ: 1 Ton

-

Premium Grade Gr1 Titanium Sheet Plate for Industrial UseNegotiableMOQ: 1 Ton

-

Supplier Wholesale Gr1、Gr2 Titanium Plate Titanium SheetNegotiableMOQ: 1 Ton

-

Titanium Plate Gr1 Gr2 Gr5 Titanium Plate / Gr1 Gr2 Gr5 Titanium Sheet PriceNegotiableMOQ: 1 Ton

-

Titanium ASTM B265 Gr1 Gr2 Plate Titanium Sheet for Pressure VesselNegotiableMOQ: 1 Ton

-

Hot Rolled Factory Price Available for Cutting and Welding-Gr1 Gr2 Gr3 Gr5 Titanium Plate/SheetNegotiableMOQ: 1 Ton

-

Industrial Titanium Rod 10mm Diameter Precision Tolerance High Temperature Resistant 1500mm Titanium BarNegotiableMOQ: 100 Kilograms

-

10mm Diameter Industrial Titanium Rod High Temperature Resistant Precision Tolerance 1500mm Titanium BarNegotiableMOQ: 100 Kilograms

-

Industrial Titanium Rod High Temperature Resistant 10mm Diameter 1500mm Length Precision Tolerance Titanium BarNegotiableMOQ: 100 Kilograms