Gr2 Gr5 Industrial Pure Titanium TA1 Titanium Alloy Square Bar High Temperature Solid Square Round Titanium Bar

Product Overview

Our company proudly presents the Gr2 and Gr5 industrial pure titanium TA1 titanium alloy square and round bars. These bars are a remarkable combination of advanced material science and precision manufacturing, designed to meet the diverse and demanding needs of various industrial applications. Titanium, known for its exceptional properties, makes these bars a top - choice for industries seeking high - performance materials.

Material and Grade

We offer these bars in two key grades: Gr2 and Gr5. Grade 2 titanium is an unalloyed titanium that provides excellent corrosion resistance, good formability, and high ductility. It is highly weldable and can withstand a wide range of chemical environments, making it suitable for applications where corrosion is a concern. On the other hand, Grade 5 titanium, also known as Ti - 6Al - 4V, is an alpha - beta alloy. It combines the strength of alpha titanium with the ductility of beta titanium. Grade 5 offers high strength - to - weight ratio, good fatigue resistance, and is able to maintain its mechanical properties at elevated temperatures, making it ideal for high - stress and high - temperature applications.

Shape and Design

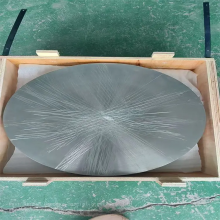

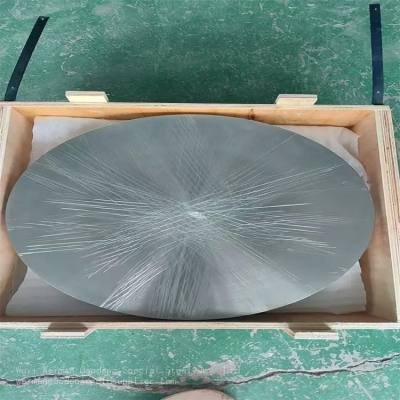

These titanium bars come in two classic shapes: square and round. The square bars provide a flat and stable surface, which is beneficial for applications where a planar contact or a specific geometric fit is required. They can be easily machined, welded, or joined to other components. The round bars, with their circular cross - section, offer uniform stress distribution, making them suitable for applications such as shafts, rods, and structural elements where rotational or linear motion is involved. The round shape also allows for smooth handling and easy installation in various machinery and equipment.

Manufacturing Technique

Our bars are produced using the forged technique. Forging is a process that involves applying compressive forces to shape the metal. This method enhances the internal grain structure of the titanium, resulting in improved mechanical properties such as higher strength, better toughness, and enhanced fatigue resistance. The forging process also eliminates internal voids and porosity, ensuring the integrity and reliability of the bars. Each bar is forged to precise dimensions, with tight tolerances maintained throughout the manufacturing process to guarantee consistent quality.

Industrial Applications

These titanium bars have a wide range of industrial applications. In the aerospace industry, the high strength - to - weight ratio of Grade 5 bars makes them perfect for aircraft components such as landing gear, engine parts, and structural frames. The corrosion resistance of Grade 2 bars is highly valued in the marine industry for applications like shipbuilding, offshore platforms, and desalination plants. In the chemical processing industry, both grades are used for equipment such as reactors, heat exchangers, and piping systems due to their excellent corrosion resistance. They are also used in the medical field for surgical implants because of their biocompatibility, as titanium does not cause adverse reactions in the human body.

Quality Assurance

We are a professional manufacturer with a strong commitment to quality. Since our establishment in 2017, we have built a reputation for producing high - quality products. Our team of 11 - 20 experienced salespersons ensures that every customer's needs are met with personalized service. We export products worth US$5 million - US$10 million annually to a wide range of markets including North America, South America, Europe, Asia, Africa, and Oceania. Each bar undergoes strict quality control measures, from the selection of raw materials to the final inspection. We adhere to international quality standards to guarantee that our titanium bars meet or exceed the expectations of our global customers.

Technical Specifications

- Diameter/Rectangular Dimensions: We can provide bars with a wide range of diameters for round bars and side lengths for square bars to meet different customer requirements.

- Length: The bars can be customized in length according to the specific needs of the application, ensuring minimal waste and maximum efficiency.

- Surface Finish: The bars have a smooth surface finish, which not only enhances their aesthetic appeal but also reduces friction and wear in applications where the bars come into contact with other components.

In conclusion, our Gr2 and Gr5 industrial pure titanium TA1 titanium alloy square and round bars are a reliable and high - performance solution for a multitude of industrial applications. Their excellent material properties, combined with our precision manufacturing and strict quality control, make them a top choice for customers around the world.

Send Inquiry to This Supplier

You May Also Like

-

Premium Grade Gr1 Titanium Sheet Plate for Industrial UseNegotiableMOQ: 1 Ton

-

Supplier Wholesale Gr1、Gr2 Titanium Plate Titanium SheetNegotiableMOQ: 1 Ton

-

Titanium Plate Gr1 Gr2 Gr5 Titanium Plate / Gr1 Gr2 Gr5 Titanium Sheet PriceNegotiableMOQ: 1 Ton

-

Titanium ASTM B265 Gr1 Gr2 Plate Titanium Sheet for Pressure VesselNegotiableMOQ: 1 Ton

-

Hot Rolled Factory Price Available for Cutting and Welding-Gr1 Gr2 Gr3 Gr5 Titanium Plate/SheetNegotiableMOQ: 1 Ton

-

Industrial Titanium Rod 10mm Diameter Precision Tolerance High Temperature Resistant 1500mm Titanium BarNegotiableMOQ: 100 Kilograms

-

10mm Diameter Industrial Titanium Rod High Temperature Resistant Precision Tolerance 1500mm Titanium BarNegotiableMOQ: 100 Kilograms

-

Industrial Titanium Rod High Temperature Resistant 10mm Diameter 1500mm Length Precision Tolerance Titanium BarNegotiableMOQ: 100 Kilograms

-

Precision Tolerance Industrial Titanium Rod 10mm Diameter 1500mm Length High Temperature Resistant Titanium BarNegotiableMOQ: 100 Kilograms

-

1500mm Length Industrial Titanium Rod 10mm Diameter High Temperature Resistant Precision Tolerance Titanium BarNegotiableMOQ: 100 Kilograms