Titanium ASTM B265 Gr1 Gr2 Plate Titanium Sheet for Pressure Vessel

Product Overview

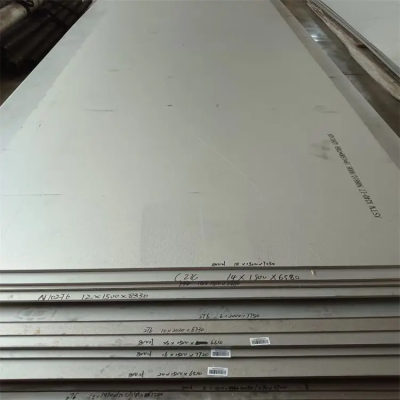

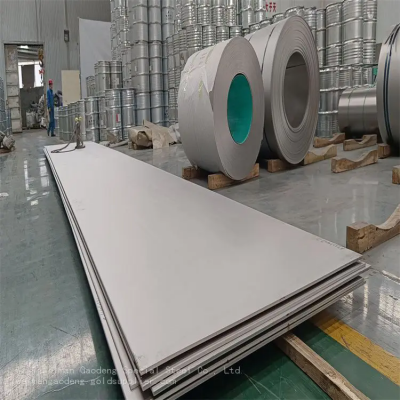

Our Titanium ASTM B265 Gr1 Gr2 Plate Titanium Sheet is a top - notch product specifically designed for pressure vessel applications. This high - quality sheet combines the excellent properties of titanium with strict compliance to ASTM B265 standards, ensuring reliability and performance in demanding industrial environments.

Material Grade and Quality

- Grade Selection: We offer two grades, Gr1 and Gr2. Grade 1 titanium is known for its high ductility and excellent corrosion resistance. It has the lowest strength among commercially pure titanium grades but is extremely formable, making it suitable for applications where complex shaping is required. Grade 2 titanium, on the other hand, has slightly higher strength while still maintaining good ductility and corrosion resistance. It is a popular choice in a wide range of industrial applications due to its balanced properties.

- Quality Assurance: Our titanium sheets are produced with the highest quality control measures. They are hot - rolled using advanced techniques, which not only ensures the desired thickness and flatness but also enhances the internal structure of the material. The hot - rolling process refines the grain structure of the titanium, improving its mechanical properties such as strength and toughness.

Physical and Mechanical Properties

- Shape: The sheets are round in shape, which provides a uniform distribution of stress when used in pressure vessels. This shape is beneficial as it helps to minimize stress concentrations, reducing the risk of failure under pressure.

- Density: Titanium has a relatively low density compared to other metals, which is a significant advantage in pressure vessel applications. The low density means that the overall weight of the pressure vessel can be reduced without sacrificing strength, leading to cost savings in transportation and installation.

- Strength and Ductility: As mentioned earlier, Gr1 and Gr2 titanium offer a good balance of strength and ductility. The sheets can withstand high pressures without undergoing significant deformation. The ductility also allows for some degree of plastic deformation before failure, providing an additional safety margin in pressure vessel design.

Application in Pressure Vessels

- Corrosion Resistance: One of the most important properties of titanium in pressure vessel applications is its outstanding corrosion resistance. Pressure vessels often come into contact with various corrosive substances, such as acids, alkalis, and saltwater. Titanium's natural oxide layer provides a protective barrier that prevents corrosion, ensuring the long - term integrity of the pressure vessel.

- High - Temperature Performance: Titanium can maintain its mechanical properties at relatively high temperatures. In pressure vessel applications, where the internal temperature can rise due to the process being carried out, the ability of titanium to retain its strength and corrosion resistance is crucial. This allows the pressure vessel to operate safely and efficiently under a wide range of temperature conditions.

Manufacturing and Customization

- Manufacturing Process: Our manufacturing process involves strict quality control at every step. From the selection of raw materials to the final inspection of the finished product, we ensure that each titanium sheet meets the highest standards. The hot - rolling technique used in production is carefully monitored to achieve the desired thickness tolerance and surface finish.

- Customization Options: We understand that different pressure vessel applications may have specific requirements. Therefore, we offer customization services. We can provide titanium sheets in various thicknesses, diameters, and surface finishes according to your specific needs. Whether you need a small - scale prototype or a large - scale production run, we have the capabilities to meet your demands.

Market and Global Reach

Our company, a well - established manufacturer since 2017, has a significant presence in the international market. With an annual export share ranging from US$5 Million - US$10 Million, we have a dedicated team of 11 - 20 sales representatives. Our products are sold in a wide range of markets including North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, and South Asia, as well as the domestic market. This global reach is a testament to the quality and reliability of our Titanium ASTM B265 Gr1 Gr2 Plate Titanium Sheet for pressure vessel applications.

Send Inquiry to This Supplier

You May Also Like

-

1500mm Length Industrial Titanium Rod 10mm Diameter High Temperature Resistant Precision Tolerance Titanium BarNegotiableMOQ: 100 Kilograms

-

Pure Titanium Rod 99.95% Purity Brushed Surface 8mm Diameter 1200mm Titanium BarNegotiableMOQ: 100 Kilograms

-

99.95% Purity Pure Titanium Rod 8mm Diameter Brushed Surface 1200mm Titanium BarNegotiableMOQ: 100 Kilograms

-

Pure Titanium Rod 8mm Diameter 99.95% Purity 1200mm Length Brushed Surface Titanium BarNegotiableMOQ: 100 Kilograms

-

Brushed Surface Pure Titanium Rod 8mm Diameter 99.95% Purity 1200mm Titanium BarNegotiableMOQ: 100 Kilograms

-

1200mm Length Pure Titanium Rod 8mm Diameter Brushed Surface 99.95% Purity Titanium BarNegotiableMOQ: 100 Kilograms

-

Medical Grade Titanium Rod TC4 Material Polished Surface 10mm Diameter Corrosion Resistant Titanium BarNegotiableMOQ: 100 Kilograms

-

Gr5 Material Medical Grade Titanium Rod 10mm Diameter Polished Surface Corrosion Resistant Titanium BarNegotiableMOQ: 100 Kilograms

-

Medical Grade Titanium Rod 10mm Diameter Gr5 Material Corrosion Resistant Polished Surface Titanium BarNegotiableMOQ: 100 Kilograms

-

Corrosion Resistant Medical Grade Titanium Rod 10mm Diameter Polished Surface TC4 Material Titanium BarNegotiableMOQ: 100 Kilograms