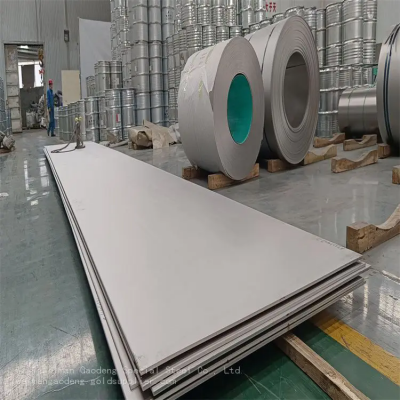

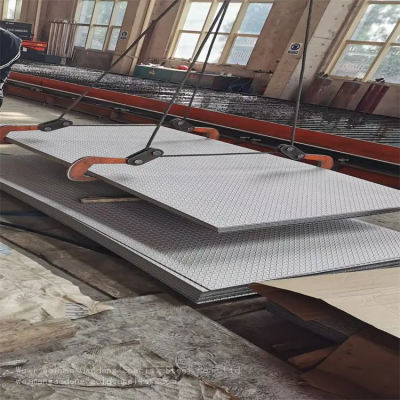

Hot Rolled Factory Price Available for Cutting and Welding-Gr1 Gr2 Gr3 Gr5 Titanium Plate/Sheet

Product Overview

Our hot - rolled titanium plates and sheets are a remarkable choice for various industrial applications. Crafted with precision, these products come in different grades including Gr1, Gr2, Gr3, and Gr5, each offering unique characteristics to meet diverse needs.

Grade - Specific Features

Gr1 Titanium: This grade is known for its excellent corrosion resistance. It contains a very low amount of interstitial elements, which makes it highly ductile. In environments where chemical exposure is a concern, such as in the chemical processing industry or marine applications, Gr1 titanium sheets can withstand the harsh conditions without significant degradation. The high ductility also allows for easy forming into complex shapes, making it suitable for fabricating components like tanks, piping systems, and heat exchangers.

Gr2 Titanium: With slightly higher strength compared to Gr1, Gr2 titanium still maintains good corrosion resistance. It is a popular choice for general - purpose applications where a balance between strength and corrosion resistance is required. The increased strength makes it ideal for structural components in the aerospace and automotive industries. For example, it can be used to manufacture aircraft frames and engine parts that need to withstand high stress while remaining resistant to corrosion.

Gr3 Titanium: This grade offers even greater strength than Gr2. It has a higher oxygen content, which contributes to its enhanced mechanical properties. In applications where high - strength materials are needed, such as in the production of high - pressure vessels and some military equipment, Gr3 titanium plates are a reliable option. The strength of Gr3 allows for the design of lighter - weight structures without sacrificing performance.

Gr5 Titanium: Also known as Ti - 6Al - 4V, Gr5 is the most widely used titanium alloy. It combines high strength, good corrosion resistance, and excellent heat resistance. In the aerospace industry, Gr5 titanium is used for critical components like landing gear, turbine blades, and wing structures. Its high strength - to - weight ratio makes it an ideal material for applications where weight reduction is crucial, such as in the construction of aircraft and spacecraft.

Hot - Rolling Technique

The hot - rolling process used in the production of these titanium plates and sheets is a key factor in their quality. During hot rolling, the titanium is heated to a high temperature and then passed through a series of rollers. This process not only gives the sheets their desired thickness and shape but also improves their mechanical properties. The hot - rolled sheets have a uniform grain structure, which enhances their strength and toughness. Additionally, the hot - rolling process reduces internal stresses in the material, making the sheets more stable and less prone to warping or cracking during subsequent processing such as cutting and welding.

Cutting and Welding Capabilities

One of the significant advantages of our titanium plates and sheets is their excellent cutting and welding properties. They can be easily cut using various methods, including plasma cutting, laser cutting, and water jet cutting. Plasma cutting is a fast and efficient method that can be used for thick sheets, while laser cutting offers high precision and is suitable for intricate designs. Water jet cutting is a non - thermal process that causes minimal heat - affected zones, which is ideal for materials like titanium that are sensitive to heat. When it comes to welding, our titanium products can be welded using common welding techniques such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding. The proper welding of these sheets results in strong and reliable joints. The high - quality welds ensure the integrity of the fabricated structures, whether they are used in industrial machinery, architectural projects, or transportation equipment.

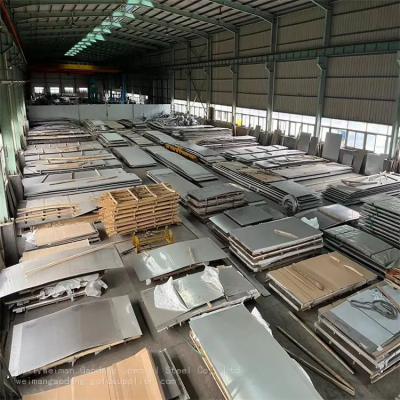

Factory Price Advantage

As a manufacturer, we are able to offer these high - quality hot - rolled titanium plates and sheets at factory prices. By eliminating middlemen, we can provide our customers with cost - effective solutions without compromising on quality. Our direct - to - customer approach allows us to pass on the savings to you, making our products a competitive choice in the global market. Whether you are a large - scale industrial manufacturer or a small - business owner, our factory prices enable you to acquire the materials you need at an affordable rate.

Applications

These titanium plates and sheets find extensive use in a wide range of industries. In the industrial sector, they are used for manufacturing chemical processing equipment, power generation components, and desalination plants. In the aerospace industry, they are crucial for building aircraft and spacecraft structures. The automotive industry also benefits from their use in engine parts, exhaust systems, and suspension components. Moreover, in the medical field, titanium is used for implants due to its biocompatibility, and our sheets can be processed into various medical devices.

Company Background

We are a professional manufacturer founded in 2017. Our company, with its team of 11 - 20 experienced sales representatives, has an annual export share ranging from US$5 Million - US$10 Million. We have a wide - reaching market presence, supplying our products to North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid - East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, as well as serving the domestic market. Our commitment to quality and customer satisfaction has allowed us to build a strong reputation in the industry. We ensure that all our products meet the highest international standards, providing you with reliable and high - performance titanium plates and sheets.

Send Inquiry to This Supplier

You May Also Like

-

Pure Titanium Rod 99.95% Purity Brushed Surface 8mm Diameter 1200mm Titanium BarNegotiableMOQ: 100 Kilograms

-

99.95% Purity Pure Titanium Rod 8mm Diameter Brushed Surface 1200mm Titanium BarNegotiableMOQ: 100 Kilograms

-

Pure Titanium Rod 8mm Diameter 99.95% Purity 1200mm Length Brushed Surface Titanium BarNegotiableMOQ: 100 Kilograms

-

Brushed Surface Pure Titanium Rod 8mm Diameter 99.95% Purity 1200mm Titanium BarNegotiableMOQ: 100 Kilograms

-

1200mm Length Pure Titanium Rod 8mm Diameter Brushed Surface 99.95% Purity Titanium BarNegotiableMOQ: 100 Kilograms

-

Medical Grade Titanium Rod TC4 Material Polished Surface 10mm Diameter Corrosion Resistant Titanium BarNegotiableMOQ: 100 Kilograms

-

Gr5 Material Medical Grade Titanium Rod 10mm Diameter Polished Surface Corrosion Resistant Titanium BarNegotiableMOQ: 100 Kilograms

-

Medical Grade Titanium Rod 10mm Diameter Gr5 Material Corrosion Resistant Polished Surface Titanium BarNegotiableMOQ: 100 Kilograms

-

Corrosion Resistant Medical Grade Titanium Rod 10mm Diameter Polished Surface TC4 Material Titanium BarNegotiableMOQ: 100 Kilograms

-

Polished Surface Medical Grade Titanium Rod 10mm Diameter Gr5 Material Corrosion Resistant Titanium BarNegotiableMOQ: 100 Kilograms