Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

-40°C to 70°C

Output voltage

24V DC (±10%)

Dimensions

145mm×100mm×28mm

I. Overview

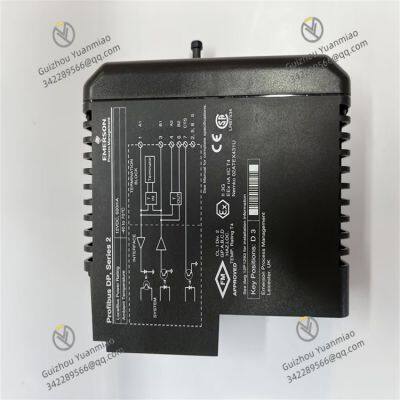

VE4022 is an M-series analog output interface card in Emerson's DeltaV™ system. Its main function is to convert the digital control signals from the DeltaV™ control system into analog signals (such as current and voltage signals) recognizable by industrial on-site equipment, realizing precise control of actuators (such as control valves, frequency converters, servo motors, etc.).

With stable signal output performance and strong environmental adaptability, this interface card is widely used in process industrial scenarios such as liquid level regulation of chemical reactors, flow control of oil pipelines, and pressure regulation of power systems. It serves as an important bridge connecting the control system and on-site executive equipment, ensuring that the production process runs stably according to preset process parameters.

II. Technical Parameters

Channel configuration: Includes 8 independent analog output channels. The channels adopt electrical isolation design, and the output signal type can be set independently for each channel, avoiding signal interference between channels and ensuring the independence and stability of control signals.

Signal type support: Supports 4-20mA DC current signal and 0-10V DC voltage signal output. These two signal types can be flexibly configured through software, adapting to the signal requirements of different actuators and improving the compatibility of the system.

Output accuracy: The output accuracy of current signals is ±0.1% of full scale, and that of voltage signals is ±0.15% of full scale, ensuring the accuracy of control signals and enabling actuators to accurately respond to the instructions of the control system.

Resolution: 16-bit D/A conversion resolution, which can realize fine adjustment of output signals, meeting the needs of high-precision control scenarios, such as micro-adjustment in precision chemical production.

Load capacity: The maximum load resistance for current output is 750Ω, and the minimum load resistance for voltage output is 1kΩ. It can drive most industrial standard actuators without the need for additional signal amplification equipment.

Isolation performance: Photoelectric isolation is adopted between the channel and the system, with an isolation voltage of ≥2500V AC (for 1 minute). It has strong anti-electromagnetic interference ability and can work stably in the complex electromagnetic environment of industrial sites.

Power parameters: The working voltage is 24V DC (±10%), and the typical power consumption of a single card is ≤5W. It is compatible with the standard power module of the DeltaV™ system, simplifying the system power supply design.

Environmental adaptability: The operating temperature range is -40°C to 70°C, the storage temperature range is -40°C to 85°C, the relative humidity is 5%-95% (no condensation), and the protection level reaches IP20. It can run reliably in harsh industrial environments such as high temperature, humidity, and heavy dust.

Response time: The establishment time of the output signal is ≤10ms, which can quickly respond to the instruction changes of the control system, meeting the requirements of real-time control, such as quickly adjusting the valve opening to cope with sudden changes in process parameters.

Physical specifications: Adopts a DIN rail-compatible card design, with dimensions of 145mm×100mm×28mm (length × width × height) and a weight of about 200g. It supports hot-swapping, facilitating online maintenance and replacement of the system.

III. Functional Features

High-precision control output: Uses a 16-bit D/A converter and high-precision signal conditioning circuit, combined with advanced linear correction algorithms, to ensure high precision and good linearity of the output signal. This enables actuators to act accurately according to the instructions of the control system, improving the control precision of the production process.

Flexible signal configuration: The 8 channels can be independently configured as current or voltage output signals respectively. They can adapt to different types of actuators without replacing hardware, reducing the difficulty of equipment selection and inventory costs, and enhancing the flexibility and expandability of the system.

Enhanced anti-interference design: The isolation design between channels and from the system, combined with hardware filtering and electromagnetic compatibility optimization, effectively resists the impact of electromagnetic interference, voltage fluctuations, etc. in industrial sites, ensures the stability of the output signal, and reduces control deviations caused by interference.

Hot-swapping and plug-and-play: Supports hot-swapping function, allowing direct plugging and unplugging of the card for replacement or maintenance during system operation without stopping the control system, reducing production downtime; it can be automatically recognized after being connected to the DeltaV™ system, and channel parameters can be configured through configuration software, simplifying the installation and commissioning process and improving work efficiency.

Comprehensive fault diagnosis: Equipped with functions such as output short-circuit protection, overcurrent protection, and signal over-range monitoring. It can monitor the channel fault status in real time and timely feedback fault information through the DeltaV™ system alarm mechanism, facilitating maintenance personnel to quickly locate and eliminate faults, and improving the reliability and maintainability of the system.

IV. Common Faults and Solutions

Excessive deviation of output signal

Possible causes: Incorrect channel calibration parameters; load mismatch in the output loop; attenuation or interference of the signal cable; hardware failure of the channel.

Solutions: Re-calibrate the channel through the DeltaV™ engineer station, and use standard instruments to verify the output accuracy; check the actuator load parameters to ensure they match the load capacity of the interface card; replace the signal cable with good shielding performance, keep it away from high-voltage equipment and interference sources, and ensure the cable shield is grounded at one end; switch the control signal to the backup channel, if the output is normal, it is determined that the original channel has a hardware fault, and replace the interface card.

No output signal

Possible causes: The channel is mistakenly set to disabled state; the output loop is broken or the connector is loose; actuator failure leads to abnormal load; the channel output circuit is damaged.

Solutions: Check the channel enable status in the configuration software and enable the disabled channel; check the continuity of the output signal cable and re-tighten the connector; detect the working status of the actuator and replace the faulty actuator; use a multimeter to detect the channel output signal, if it is confirmed that there is no output, it is determined that the channel has a hardware fault, and replace the interface card.

Frequent fluctuation of output signal

Possible causes: Unstable output instructions of the control system; strong electromagnetic interference on site; the output cable is not a shielded cable or the shield is not grounded; improper setting of filtering parameters.

Solutions: Check the output instructions of the control system to eliminate problems with the control algorithm or parameter settings; keep the output cable away from strong interference sources such as frequency converters and motors, use twisted-pair shielded cables and ensure the shield is reliably grounded; adjust the filtering parameters of the output channel in the configuration software, and increase the filtering time constant to smooth the output signal.

The card cannot be recognized by the system

Possible causes: The card is not correctly inserted into the slot, resulting in poor contact of the golden fingers; the card firmware version is incompatible with the system; abnormal power supply; internal circuit failure of the card.

Solutions: Re-plug the card to ensure close contact with the slot; upgrade the card firmware to a version matching the DeltaV™ system; check the output voltage of the power module and replace the faulty power module; if the above operations are ineffective, it is determined that the card has a hardware fault, and replace it with a new card.