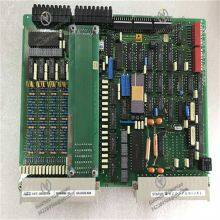

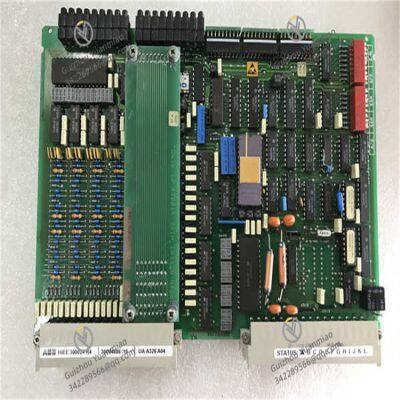

ABB HIEE300024R4, also known as UAA326A04, is a controller module meticulously designed for industrial automation systems. Produced in Sweden, a leading industrial nation, it embodies ABB's profound technical heritage in the field of automation control. As a key component in various Programmable Logic Controller (PLC) and Distributed Control System (DCS) applications, it acts like an "intelligent brain" in industrial production, undertaking the important tasks of precise control and real-time monitoring of industrial processes. It ensures the efficient and reliable operation of the entire production process, providing solid technical support for the advancement of industrial automation.

Highlights of Excellent Performance

Send Inquiry to This Supplier

You May Also Like

-

ABB Bailey SPBRC400 Bridge ControllerNegotiableMOQ: 1 Unit

-

ABB Bailey SPDSI22 Digital Input ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey SPDSO14 Digital Output ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey SPNPM22 Network Processing ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey IMDS014 Digital Slave Output ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey IMDSI14 Digital Input ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey IMDSM04 Digital Slave Input/Output ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey IMDSO14 Digital Output ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey IMFEC12 High-Level Analog Input ModuleNegotiableMOQ: 1 Unit

-

ABB Bailey IMMFP12 Multifunction Processor ModuleNegotiableMOQ: 1 Unit