Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating temperature

-25°C–+60°C

Humidity

5%–95% (non-condensing)

Power supply

24VDC (±20%)

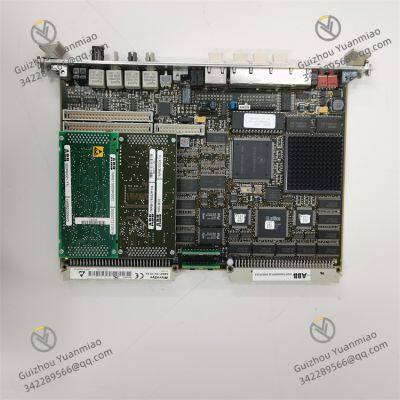

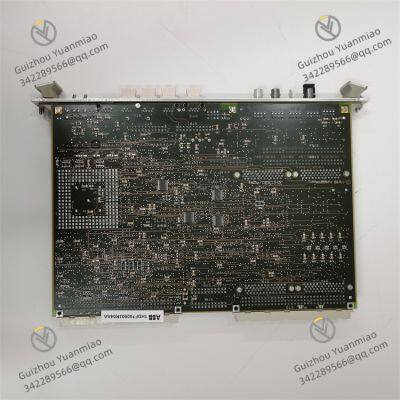

ABB 500CPU03 1HDF700003R5122I. Positioning and Applications

Series Affiliation: Central Processing Unit (CPU) module of ABB AC 500 series PLC, serving as the core control unit of the system. It is responsible for executing user programs, processing input/output signals, and coordinating communication between modules.

Core Functions: Supports logic control, data computation, motion control, and communication management. Suitable for medium to large industrial automation systems, such as production line control, process automation, and mechanical equipment scenarios.

II. Technical Parameters and Characteristics1. Hardware Performance

Processor: 32-bit high-performance microprocessor with a main frequency ≥100MHz, supporting floating-point operations.

Memory:

Program memory: 256KB–1MB (depending on the model) for storing user programs.

Data memory: 512KB–2MB, supporting real-time data storage and processing.

I/O Expansion Capability: Can connect up to 128 I/O modules, supporting distributed expansion (connecting remote I/O via communication modules).

2. Communication Interfaces and Protocols

Integrated Interfaces:

1 RJ45 Ethernet interface (supporting protocols such as EtherNet/IP, Modbus TCP, and Profinet).

1 RS-485/RS-232 serial port (supporting Modbus RTU, ASCII, or custom protocols).

Protocol Support:

Industrial Ethernet: EtherNet/IP, Modbus TCP, EtherCAT (requires expansion module).

Fieldbus: CANopen (requires expansion communication module).

Programming interface: Supports program download via USB or Ethernet.

3. Performance Parameters

Scan cycle: ≤0.1ms/K instruction (basic logic instructions), suitable for high-speed control scenarios.

Real-time performance: Supports hardware interrupts (response time ≤100μs), meeting emergency signal processing requirements.

Storage expansion: Supports SD cards (up to 32GB) for program backup and data log storage.

4. Electrical and Environmental Characteristics

Power supply: 24VDC (±20%), power consumption ≤15W.

Isolation: Electrical isolation between power supply and I/O (1500V AC/1min), with strong anti-interference capability.

Mounting method: 35mm DIN rail mounting, supports vertical/horizontal installation.

Operating temperature: -25°C–+60°C, humidity 5%–95% (non-condensing).

III. Application ScenariosManufacturing Automation

Process Control

Distributed Systems

Communicates with SCADA systems (such as Wonderware, WinCC) via Ethernet interfaces to achieve remote monitoring.

Connects remote I/O modules (such as ABB 500I/O series) as a master station to build distributed control systems.

IV. Interfaces and Wiring1. Hardware Interface Layout

Ethernet interface: Labeled as ETH, supporting 10/100Mbps auto-negotiation, can connect to switches or upper computers.

Serial port: DB9 interface, default RS-485 mode (half-duplex), can be configured as RS-232 (full-duplex) via software.

Programming interface: USB interface (Type-B) for connecting to programming computers (using ABB Control Builder software).

Expansion interface: Backplane bus interface for connecting I/O modules and communication modules (such as 500CMP04).

2. Typical Wiring Example (Modbus RTU Master)

RS-485 wiring:

Module TXD+ connected to bus terminal A, TXD- connected to bus terminal B.

Terminal resistors (120Ω) connected to both ends of the bus to reduce signal reflection.

V. Configuration and Debugging1. Software Tools

2. Status Diagnosis

VI. Comparison with Similar Modules (vs. 500CPU02, 500CPU04)

| Comparison Dimension | 500CPU03 | 500CPU02 | 500CPU04 |

|---|

| Processor Performance | 32-bit/100MHz | 32-bit/80MHz | 32-bit/150MHz |

| Program Memory | 512KB | 256KB | 1MB |

| Communication Interfaces | 1×ETH + 1×RS-485/232 | 1×ETH + 1×RS-485/232 | 2×ETH + 1×RS-485/232 |

| Maximum I/O Count | 128 modules | 64 modules | 256 modules |

| Applicable Scenarios | Medium complex control systems | Small logic control | Large high-speed control systems |

VII. Conclusion

As a mid-range CPU module of the AC 500 series, ABB 500CPU03 combines high-performance computing capabilities with flexible communication expansion capabilities, suitable for medium to large industrial automation systems that require a balance of logic control, data processing, and cross-protocol communication. Its high real-time performance, anti-interference design, and rich programming interfaces make it a core component for building reliable automation solutions in manufacturing, power, energy, and other fields. For higher performance or more interfaces, upgrading to the 500CPU04 model is recommended; if the system scale is small, 500CPU02 is a more economical choice.