Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Operating voltage

24 VDC

Power consumption

Typical value ≤5 W

I. Positioning and Applications

Series Affiliation: Communication Module of ABB AC 500 series PLC, used to expand the system's network communication capabilities and enable data interaction between the PLC and external devices, host computers, or other control systems.

Core Functions:

Supports multiple industrial communication protocols, adapting to different automation network architectures.

Serves as a communication hub for the AC 500 system with sensors, actuators, human-machine interfaces (HMIs), or remote monitoring systems.

Suitable for scenarios requiring cross-network data transmission, such as intelligent manufacturing, process control, and building automation.

II. Technical Parameters and Characteristics

Communication Interfaces and Protocols

Interface Types:

2 RJ45 Ethernet interfaces (supporting 10/100 Mbps auto-negotiation), compatible with ring network topologies (e.g., FastTrack redundant network).

1 RS-485 serial interface (supporting protocols like Modbus RTU and ASCII).

Supported Protocols:

Ethernet: EtherNet/IP, Modbus TCP, ABB Ability™ communication protocol, SNTP (network time synchronization).

Serial: Modbus RTU Master/Slave, free port communication (user-defined protocols).

Electrical Characteristics

Operating voltage: 24 VDC (powered by the rack power supply module).

Power consumption: Typical value ≤5 W.

Isolation protection: Electrical isolation between Ethernet interfaces and internal circuits (isolation voltage 1500 VAC) for electromagnetic interference resistance.

Data Transmission Capability

III. Functional Highlights and Technical Features

Network Redundancy and Reliability

Ring Network Support: FastTrack redundant ring networks can be formed via Ethernet interfaces, with self-healing time<50 ms during faults to ensure communication continuity.

Disconnection Detection and Recovery: Supports real-time network status monitoring, automatically triggering alarms and attempting reconnection when disconnections occur.

Protocol Conversion and Multi-Network Interconnection

Can act as a protocol gateway to enable data conversion between EtherNet/IP and Modbus RTU networks (e.g., connecting third-party Modbus devices to Ethernet).

Supports concurrent operation of multiple protocols (e.g., handling EtherNet/IP communication and Modbus RTU slave requests simultaneously).

Configuration and Monitoring

Visually configure communication parameters and protocol mapping tables via Control Builder AC 500 software.

Panel LED indicators (Link, Activity, Error) display network status in real time, supporting fault early warning.

IV. Typical Application Scenarios

| Industry | Application Case | Communication Requirements |

|---|

| Intelligent Manufacturing | Production line equipment networking | EtherNet/IP communication with robots and vision systems |

| Energy Management | Substation data acquisition | Modbus TCP integration with SCADA systems |

| Water Treatment | Remote pump station monitoring | Serial interface connection to field instruments (Modbus RTU) |

| Rail Transit | Signal system redundant communication | High-reliability data transmission in ring network architectures |

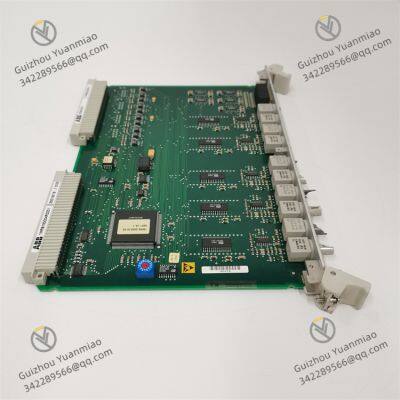

V. Interfaces and Wiring ExamplesHardware Interface Layout

Ethernet interfaces: 2 RJ45 ports (labeled "NET1" and "NET2"), supporting direct connection or networking via switches.

RS-485 interface: 3-pin terminal block (+, -, GND), supporting shielded cable connections to reduce interference.

Status indicators:

Link (green): Illuminates when Ethernet link is connected.

Activity (orange): Flashes during data transmission.

Error (red): Illuminates in case of communication faults or configuration errors.

Ring Network Wiring Example

Connect the NET1 and NET2 interfaces of two 500SCM01 modules end-to-end to form a ring network, expand nodes via switches in between, and the system automatically configures redundant paths.

VI. Comparison with Similar Modules (500SCM02, 500SCM12)

| Comparison Dimension | 500SCM01 | 500SCM02 | 500SCM12 |

|---|

| Communication Interfaces | 2× Ethernet + 1× RS-485 | 2× Ethernet + 2× RS-485 | 4× Ethernet (no serial interface) |

| Supported Protocols | EtherNet/IP, Modbus, etc. | Added CANopen master/slave | Focused on Ethernet (supports PROFINET) |

| Redundancy Functions | FastTrack ring network | Supports CANopen redundancy | PROFINET ring network |

| Application Scenarios | General Ethernet + serial communication | Devices requiring CANopen interfaces | Large PROFINET networks |

VII. Configuration and Debugging Essentials

Installation and Network Setup

Insert into the communication slot of the AC 500 rack, powered via the backplane bus.

Ethernet interfaces require IP address configuration (static or DHCP); enable the "FastTrack" function in software for ring network mode.

Protocol Configuration Example (Modbus TCP Master)

Create a Modbus TCP master task in Control Builder, specifying slave IP, port (default 502), and data mapping tables (e.g., reading holding register addresses 40001–40010).

Polling cycles (e.g., 100 ms) or event-triggered communication can be set.

Fault Troubleshooting

If the Error light is on: Check network cable connections, IP address conflicts, or protocol parameter configuration errors.

For serial communication anomalies: Confirm that baud rate, data bits, and parity bits match the slave device, and inspect for loose wiring or poor grounding.

VIII. Conclusion

The ABB 500SCM01 communication module, with its core advantages of "multi-protocol compatibility + redundant design", provides flexible network expansion capabilities for AC 500 systems. Its core values include:

Strong compatibility: Simultaneously supports Ethernet and serial protocols, adapting to mixed networking of new and old devices.

High reliability: Ring network redundancy and electrical isolation designs meet anti-interference requirements in industrial fields.

Flexible configuration: Visual management of communication tasks via software reduces integration difficulty, suitable for data interaction scenarios in medium-to-large automation systems.