Material

Other, Global universal model

Condition

Other, Global universal model

Task

Other, Global universal model

Mathematical Model

Other, Global universal model

Signal

Other, Global universal model

Customized

Non-Customized

Structure

Other, Global universal model

Accuracy

±0.1% (RTD), ±0.5℃

Temperature Range

-200℃ ~ +850℃

Power Supply

24VDC (±20%)

I. Positioning and Applications

Series Affiliation: Intelligent Temperature Measurement Module of ABB AC 500 series PLC, primarily used for temperature data acquisition and processing in industrial fields. It supports access to various temperature sensors and is suitable for automation systems requiring high-precision temperature monitoring (such as chemical, metallurgical, HVAC, etc.).

Core Functions:

Real-time acquisition of temperature sensor signals (RTD, TC, etc.), conversion to digital quantities, and transmission to PLC controllers.

Supports temperature compensation, linearization processing, and fault diagnosis to ensure accuracy and reliability of measurement data.

Can be connected to the AC 500 system as an independent module or interconnected with other devices via communication interfaces.

II. Technical Parameters and Characteristics

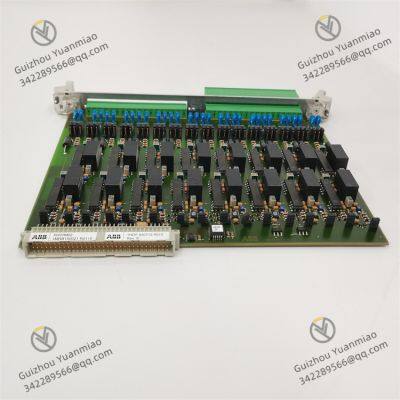

1. Input Channels and Sensor Support

2. Measurement Accuracy and Range

3. Electrical and Environmental Characteristics

Power Supply: 24VDC (±20%), power consumption ≤5W.

Isolation: Electrical isolation between channels (500V AC/1min), with strong anti-interference capability.

Mounting Method: 35mm DIN rail mounting, supporting vertical/horizontal installation.

Operating Temperature: -25℃ ~ +60℃, humidity 5%~95% (non-condensing).

III. Functional Features and Technical Highlights

Intelligent Diagnosis and Compensation

Supports open-circuit detection, short-circuit detection, and sensor fault alarms (such as over-temperature, out-of-range).

Built-in cold junction compensation (for thermocouples) and linearization algorithms to reduce measurement errors.

Communication and Data Processing

Real-time communication with AC 500 CPU via backplane bus, data update cycle ≤1ms (full channels).

Supports conversion of temperature data to engineering units (℃/℉) and direct mapping to PLC memory addresses.

Configuration Flexibility

Each channel can be independently configured for sensor type, filtering parameters (low-pass filtering), and alarm thresholds.

Supports hot-swapping, allowing module replacement without power-off for easy maintenance.

IV. Application Scenarios

Industrial Temperature Monitoring Systems

In chemical reactors, monitor material temperature via Pt100 RTD and real-time control heating/cooling systems.

In metallurgical furnaces, collect furnace temperature data using Type K thermocouples and link with PLC for closed-loop temperature control.

HVAC and Energy Management

In air conditioning systems, monitor supply/return air temperature to optimize energy consumption control.

In thermal pipe networks, achieve heat distribution and leakage detection through multi-point temperature acquisition.

Process Automation

Real-time temperature monitoring of food processing equipment (such as sterilizers) to ensure process parameters meet standards.

Temperature data acquisition and recording for freeze dryers and incubators in the pharmaceutical industry.

V. Interfaces and Wiring

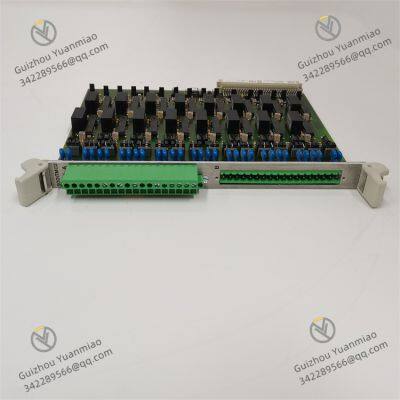

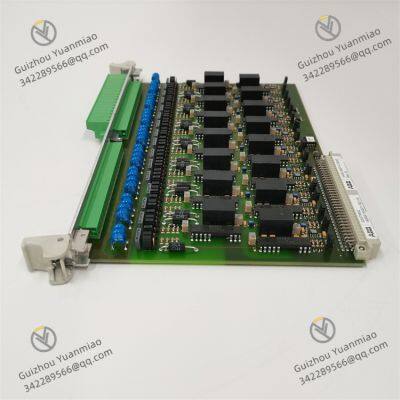

1. Hardware Interface Layout

Signal Interface: 20-pin terminal block, supporting screw or spring terminal connections for sensor cables.

Communication Interface: Backplane bus interface, inserted into the CPU rack or expansion rack of AC 500 series PLC.

2. Typical Wiring Examples

Pt100 (4-wire): Connect the 4 wires of RTD to the module's measurement terminals (e.g., A+, A-, B+, B-) without additional reference resistors.

Type K Thermocouple: Positive pole connected to "+" terminal, negative pole to "-" terminal; cold junction compensation terminals (C+, C-) need to connect compensation wires or ground.

VI. Configuration and Debugging

1. Software Tools

2. Status Diagnosis

VII. Comparison with Similar Modules (vs. 500ITM01, 500ITM03)

| Comparison Dimension | 500ITM02 | 500ITM01 | 500ITM03 |

|---|

| Channel Quantity | 8 channels (differential input) | 4 channels (differential input) | 16 channels (single-ended input) |

| Sensor Types | RTD/TC/voltage/current | RTD/TC (basic type) | RTD/TC (high-speed type) |

| Measurement Accuracy | ±0.1% (RTD) | ±0.2% (RTD) | ±0.05% (RTD) |

| Communication Cycle | ≤1ms (full channels) | ≤2ms (full channels) | ≤0.5ms (full channels) |

| Application Scenarios | Medium-scale temperature monitoring systems | Small equipment temperature acquisition | Large high-speed temperature monitoring systems |

VIII. Conclusion

As a high-performance temperature measurement module of the AC 500 series, ABB 500ITM02 provides reliable temperature monitoring solutions for industrial automation systems through multi-channel high-precision acquisition and intelligent diagnosis functions. Its advantages include:

Strong Compatibility: Supports all types of temperature sensors, adapting to measurement needs in different industrial scenarios.

Accuracy and Reliability: Electrical isolation design and built-in compensation algorithms ensure stable measurement in harsh environments.

Flexible Configuration: Independent channel parameter setting and hot-swapping function facilitate system expansion and maintenance.