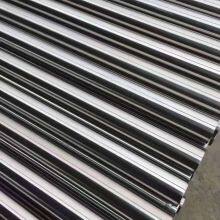

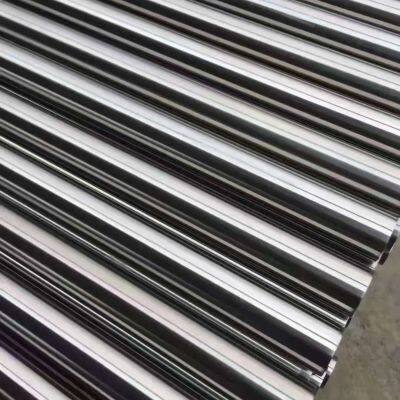

EP Electrolytic Polished Stainless Steel Pipe/Tube | ASTM A312/A269 304/316L | Mirror Finish, Corrosion Resistant | for Pharma

To assure the highest quality standards, the tubing is subjected to extensive testing and inspection programs that meet or exceed ASTM A270 A1016 A1016M test requirements. Testing includes reverse bend, reverse flattening, and flange tests. Eddy current testing is performed on 100% of the sanitary tube produced.

Heat Treatment (Annealing):

Inline hydrogen bright annealing to 1900°F (1040° C) minimum followed with a rapid quench.

Surface Finishes

Surface finish is 20 µ-in Ra (0.5 µm) ID maximum, 30 µ-in Ra (0.8 µm) OD maximum surface roughness measured per ASME ANSI B46.1 with the profilometer reading at 90 degrees to the lay. Other finishes available upon request.

Flattening Test

For material heat treated in a continuous furnace flattening tests shall be made on a sufficient number of pipes to constitute 5 % of the lot, but in no case less than 2 lengths of pipe.

Markings

Bright annealed tubing is line–stenciled with OD, wall, ASTM specifications, size, grade, heat number, production date and time. OD polished tube is marked on one end of each tube with a removable label stating ASTM specification, manufacturer, grade and heat number. Continuous line stencil available on request.

Note:

Mill test certificates will be issued according to EN10204.3

All tubes shall be supplied as per applicable ASTM A270 /A270M Specification.

Every month, we update our products on our website, hoping it can help you gain a better understanding of the Chinese market. We also offer additional services to assist you in inspecting and verifying Chinese factories and products.

We sincerely hope that Zhongzheng Stainless Steel can become a good partner for your purchase of stainless steel pipes in China.

Do you need any more steel pipes? Contact us immediately!

Send Inquiry to This Supplier

You May Also Like

-

MP Grade Stainless Steel Pipe 316L BA Clean Pipe Clean Stainless Steel Pipeline 304 Stainless Steel Bright TubeNegotiableMOQ: 1 Ton

-

316L BA Clean Pipe Clean Stainless Steel Pipeline 304 TP304 A269 Stainless Steel Sanitary Pipe Sanitary-grade Food-grade EP TubesNegotiableMOQ: 1 Ton

-

304 Seamless Sanitary Stainless Steel Pipe – 1/2 to 6, EP/BA Finish, FDA CompliantNegotiableMOQ: 1 Ton

-

EU-GMP & FDA Approved SS316L Tube – Passivation Test Report, Dust-Free Packing 304 Seamless Sanitary Stainless Steel Pipe – 1/2 to 6,NegotiableMOQ: 1 Ton

-

MP Grade Stainless Steel Pipe 316L BA Clean Pipe Clean Stainless Steel Pipeline 304 Stainless Steel Bright TubeNegotiableMOQ: 1 Ton

-

BA Stainless Steel Tube Manufacturer With Self-built Factory for Supporting Production 304 Stainless Steel Tube Sanitary-grade Food-grade EP TubesNegotiableMOQ: 1 Ton

-

MP Grade Stainless Steel Pipe 316L BA Clean Pipe Clean Stainless Steel Pipeline 304 Stainless Steel Bright TubeNegotiableMOQ: 1 Ton

-

MP Grade Stainless Steel Pipe 316L BA Clean Pipe Clean Stainless Steel Pipeline 304 Stainless Steel Bright TubeNegotiableMOQ: 1 Ton

-

EP Electrolytic Polished Stainless Steel Pipe/Tube | ASTM A312/A269 304/316L | Mirror Finish, Corrosion Resistant | for PharmaNegotiableMOQ: 1 Ton

-

EU-GMP & FDA Approved SS316L Tube – Passivation Test Report, Dust-Free Packing 304 Seamless Sanitary Stainless Steel Pipe – 1/2 to 6,NegotiableMOQ: 1 Ton