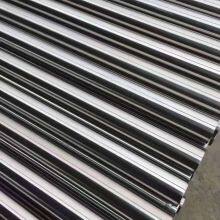

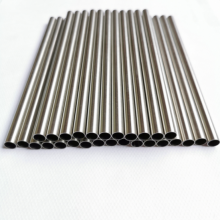

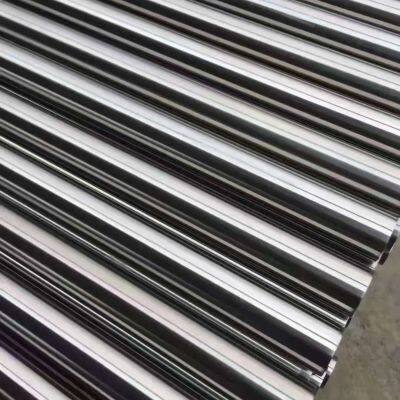

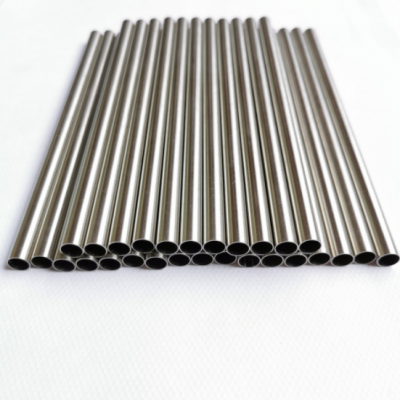

MP Grade Stainless Steel Pipe 316L BA Clean Pipe Clean Stainless Steel Pipeline 304 Stainless Steel Bright Tube

Stainless steel sanitary pipes are a type of pipe material with special uses and properties.

Definition and Standards

Definition: Stainless steel sanitary pipes generally refer to stainless - steel pipes used in industries with high - hygiene requirements such as food, beverages, pharmaceuticals, and cosmetics. They can meet the strict requirements of these industries for hygiene, safety, and corrosion resistance during fluid transportation.

Standards: Internationally, there are ASTM (American Society for Testing and Materials) standards. In China, common standards include GB/T 12771 (Stainless steel welded pipes for fluid transportation), etc. These standards clearly stipulate aspects such as the dimensions, tolerances, surface quality, chemical composition, and mechanical properties of stainless - steel sanitary pipes.

Materials

Common Materials: Mainly austenitic stainless steels, such as 304 (06Cr19Ni10) and 316L (022Cr17Ni12Mo2).

Material Characteristics: 304 stainless steel contains about 18% chromium and about 8% nickel. It has good corrosion resistance and formability, and can resist the erosion of most chemical substances. It is widely used in general - hygiene - requirement scenarios. 316L stainless steel adds molybdenum elements on the basis of 304, enhancing its corrosion - resistance in harsh environments, especially its tolerance to chlorides. It is often used in more demanding hygiene conditions or environments with special corrosion risks.

Production Process

Smelting: Advanced smelting processes such as electric arc furnaces and AOD (argon - oxygen decarburization) are adopted to ensure the purity of the molten steel and the uniformity of the chemical composition, reducing the content of impurities and harmful elements, laying a foundation for the subsequent production of high - quality sanitary pipes.

Forming: Common forming methods include welded and seamless. Welded pipes are formed by rolling stainless - steel strips into a tubular shape by a forming unit and then welding them through automatic welding equipment. The production efficiency is high, and the cost is relatively low. Seamless pipes are processed from solid stainless - steel billets into tubular shapes through processes such as piercing and tube rolling. Their structure is more compact, with better strength and corrosion resistance, but the production process is complex and the cost is high.

Heat Treatment: The formed pipes need to undergo heat treatment, such as solution treatment, to eliminate the internal stress generated during the processing, improve the structure and properties of the pipes, and enhance their corrosion resistance and toughness.

Surface Treatment: To meet hygiene requirements, stainless - steel sanitary pipes usually need to undergo strict surface treatment. Common surface treatment methods include mechanical polishing and electrolytic polishing. Mechanical polishing can make the surface of the pipes reach a certain degree of smoothness, while electrolytic polishing can further improve the flatness and smoothness of the surface, reducing the surface roughness Ra to below 0.2μm. At the same time, it can also form a passivation film on the surface of the pipes, enhancing their corrosion resistance.

Characteristics

Hygiene and Safety: The inner wall of the pipes is smooth, not easy to scale, and not easy to breed bacteria and microorganisms. It can effectively ensure the hygienic quality of the transported medium, meeting the hygiene standards of industries such as food and medicine.

Every month, we update our products on our website, hoping it can help you gain a better understanding of the Chinese market. We also offer additional services to assist you in inspecting and verifying Chinese factories and products.

We sincerely hope that Zhongzheng Stainless Steel can become a good partner for your purchase of stainless steel pipes in China.

Do you need any more steel pipes? Contact us immediately!

Send Inquiry to This Supplier

You May Also Like

-

Precision Thin Wall 304 Seamless Stainless Steel Tube, OD 3mm-50mm, Wall 0.5mm-3mmUS$ 695MOQ: 1 Ton

-

Food-grade Sanitary Pipes, With Smooth Inner Walls and no Scale, Comply With GMP Standards and Are Used in the Dairy and Beverage Industries.US$ 695MOQ: 1 Ton

-

Industrial Pipes Oil Pipelines, Heat Exchanger Pipes, Boiler Pipes (must be Resistant to High Temperature and High Pressure)NegotiableMOQ: 1 Ton

-

Shiny Surface (BA/2B): Smooth and Reflective, Suitable for Household Appliances and Decoration.US$ 695MOQ: 1 Ton

-

Mirror (8K): High Reflectivity, Used for High-end Decoration (such as Hotels, Exhibition Halls)US$ 695MOQ: 1 Ton

-

Shiny Surface (BA/2B): Smooth and Reflective, Suitable for Household Appliances and Decoration.NegotiableMOQ: 1 Ton

-

Austenitic Stainless Steel (such as 304, 316, 316L) - Corrosion-resistant, Non-magnetic, Widely Used in Food, Chemical,US$ 695MOQ: 1 Ton

-

Precision Thin Wall 304 316L Seamless Stainless Steel Tube, OD 3mm-50mm, Wall 0.5mm-3mmUS$ 695MOQ: 1 Ton

-

Medical Grade 316L Seamless Tube, Ultra-Clean Surface, for Surgical InstrumentsUS$ 695MOQ: 1 Ton

-

Small Diameter 304 Seamless Pipe, OD 1mm-10mm, for Instrumentation & SensorsNegotiableMOQ: 1 Ton