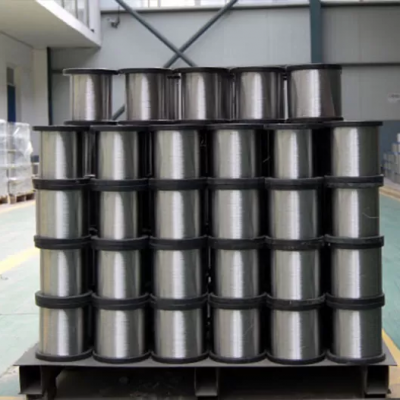

Diameter: 0.016-5mm or customized

Type: Monel 400 wire, Monel K500 wire

Standard: AISI, ASTM, JIS, DIN, EN, BS

Surface: Matt surface, bright surface and coating

Lead Time: Stock or 3-10 days or according to quantity

Monel Alloy Wire is a high-performance alloy with nickel as the main component and copper, iron, aluminum, manganese, carbon and other elements added. The most common type of Monel wire is Monel 400 wire, followed by Monel K500 wire, which is a reinforced version of Monel 400 wire, with more aluminum and titanium than Monel 400 wire.

| Element | Monel 400 (%) | Monel K-500 (%) |

| Nickel (Ni) | 63 - 70 | 63 - 70 |

| Copper (Cu) | 28 - 34 | 28 - 34 |

| Iron (Fe) | 2 - 3 | 1.5 - 2.5 |

| Manganese (Mn) | ≤ 2 | ≤ 1 |

| Carbon (C) | ≤ 0.30 | - |

| Silicon (Si) | ≤ 0.50 | - |

| Aluminum (Al) | Small quantity | 2.3 - 3.15 |

| Titanium (Ti) | - | 0.35 - 0.85 |

Physical And Mechanical Properties

The physical and mechanical properties of Monel alloys enable them to perform well in many demanding environments.

● Density: About 8.8g /cm³ (Monel 400)

● Melting point: about 1300-1350°C

● Tensile strength: The tensile strength of the Monel 400 is about 550-760 MPa, and the Monel K-500 can reach about 1035 MPa.

● Yield strength: The Monel 400 yield strength is approximately 240 MPa, and the Monel K-500 can be as high as approximately 690 MPa.

● Ductility: Monel 400 has good ductility and is suitable for cold and hot working.

Monel alloy has excellent corrosion resistance, high temperature resistance and good mechanical strength, and is particularly suitable for harsh environments such as ocean, chemical, and petroleum. It has a wide range of industrial applications, especially in marine engineering, chemical processing and aerospace fields.

Monel Wire Features

● Corrosion Resistance

The most notable feature of Monel alloy is its excellent corrosion resistance. It has strong corrosion resistance to a variety of acids, alkalis, seawater, chlorides and various chemicals.

● High Temperature Resistance

Monel alloys have good high temperature resistance, especially Monel 400, which can work stably in high temperature environments for a long time. It still performs well in high temperature environments up to 1000°C and is suitable for certain high temperature fields, such as heat exchangers, aircraft engine components, etc.

● Good processing performance

Monel alloy has good processing properties, can be cold working, hot working and welding processing. It can be processed into various forms of products by cold rolling, hot rolling, drawing and other ways, such as sheet, pipe, bar and so on.Monel alloy has strong ductility and is suitable for manufacturing precision wires, springs, heating wires, etc.The surface treatment is diverse and can provide bright wire, oxidized wire, and plated wire

● Wear and impact resistance

High hardness and friction resistance, suitable for high-load working environment, strong impact resistance, will not become brittle due to alternating hot and cold

● Excellent mechanical properties

High strength and high toughness: maintain good performance even in low temperature environment of -100°C

High temperature resistance: still has good mechanical properties within 600°C

Non-magnetic: suitable for electronic and medical equipment with strict magnetic requirements

Monel Wire Application

● Ocean engineering: Monel alloy, due to its excellent resistance to seawater corrosion, is often used in the manufacture of ships, offshore platforms, submarine pipelines and other Marine equipment.

● Chemical and petroleum industry: Monel alloy can resist the corrosion of a variety of strong acids and chloride solutions, so it is widely used in chemical reactors, pipelines, pumps, valves and other equipment as well as filters and screens of chemical equipment.

● Aerospace: Monel alloys are used in structural components of aeroengines and other high-temperature applications due to their high temperature resistance.

● Food processing and pharmaceuticals: Monel alloys are also used in food processing equipment and pharmaceutical plants, especially where corrosion resistance and high temperature resistance are required.

● Power industry: In some high temperature, corrosive conditions, Monel alloy is also used to make boilers, heat exchangers, steam pipes and other equipment.

● Water treatment: Monel alloys are commonly used in desalination equipment, filtration units and chemical treatment facilities due to their corrosion resistance to chlorides.

● Medical equipment: Because of its non-magnetic and corrosion-resistant properties, Monel is often used in surgical instruments and human implant materials.

Cechen Monel Wire Supplier

The Monel wire produced by Cechen is at the leading level in the industry. The Monel wire we produce has good corrosion resistance and wear resistance. It is sold to more than 30 countries and regions around the world and has received good reviews from buyers. The Monel wire we produce is usually Monel 400 wire, Monel K500 wire. If you have other requirements, we can also customize it according to your needs. If you are looking for a reliable Monel wire manufacturer, you are welcome to contact us at any time.

Send Inquiry to This Supplier

You May Also Like

-

201 Stainless Steel WireNegotiableMOQ: 1000 Kilograms

-

Nickel Wire MeshNegotiableMOQ: 50 Rolls

-

Titanium Wire MeshNegotiableMOQ: 50 Rolls

-

Galvanized Wire MeshNegotiableMOQ: 50 Rolls

-

Monel Wire MeshNegotiableMOQ: 50 Rolls

-

Inconel Wire MeshNegotiableMOQ: 50 Rolls

-

Hastelloy Wire MeshNegotiableMOQ: 50 Rolls

-

Iron Wire MeshNegotiableMOQ: 50 Rolls

-

Epoxy Coated MeshNegotiableMOQ: 50 Rolls

-

Aluminum Wire MeshNegotiableMOQ: 50 Rolls