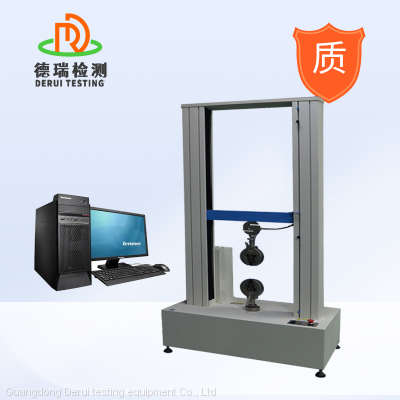

Product Description

Computerized Double Column Tensile Testing Machine is used to test the mechanical properties of various materials such as static load, tensile, compression, bending,shearing, tearing, peeling and other mechanical properties of mechanical equipment. It is suitable for plastic plates, pipes, and other materials. Various physical and mechanical performance tests of profiles, plastic films and rubber, wires and cables, steel,fiberglass and other materials are developed for materials.

Specification

| Frame capacity | 2000kg |

| Load cell brand | Germany brand load cell for high accuracy, |

| 2000kg (500,1000kg are optional) | |

| Load accuracy | 0.5% F.S |

| Control system | PC with windows 7 system |

| Motor | Panasonic servo motor w/AC variable speed drive system, high-precision mechanical ball screw rod |

| Force reading | kgf, Ibf, N, KN, T etc |

| Vertical test space | 1200mm including fixture |

| Horizontal test space | ≤400mm |

| Test speed | 0.1~500mm/min (adjustable) |

| Software | TM 2101 |

| Curves display | Load- elongation, Elongation-time, Time-elongation, Stress-strain |

| Data display | Max. force, speed, sample information, strength(Kpa, Mpa, N/mm, N/mm2) etc… |

| Safety features | E-Stop |

| Over-load protection | |

| Upper and lower limit switches | |

| Load sensor with automatic retreat |

The operation procedure of the high capacity tensile strength tester is as follows:

Pre-test preparation

Sample preparation: According to the test requirements, select the appropriate sample. For large-scale construction and bridge projects, such as steel girders for bridges, steel bars for construction, etc., it is necessary to ensure that the size and shape of the sample meet the relevant standards or test requirements. At the same time, check the appearance of the samples to ensure that there are no obvious defects or damages. For example, if testing oil drill pipe, check whether there are cracks, wear and tear on the surface of the drill pipe.

Equipment inspection: Check whether there is any damage to the appearance of the testing machine and whether the connection of each component is stable. Check whether the protective door can be opened and closed normally and whether the safety protection device is intact. Confirm that the operation interface display is normal and there is no abnormal error message.

Installation of fixture: According to the shape and size of the sample, select the appropriate fixture. For example, for testing samples with round cross-section, choose round collet; for flat samples, use flat fixture. Install the fixture on the tester and make sure that it is firmly installed, and ensure that the position of the fixture is accurate through the quick positioning device. To test large shaft parts in heavy machinery manufacturing, for example, it is necessary to install specially designed high-strength, large-size shaft fixtures.

Parameter Setting

Input sample information: In the sample specification input field of the operation interface, fill in the detailed parameters of the sample, such as length, diameter, material and so on. This information is crucial for the subsequent calculation of material mechanical property indexes.

Select test standard: According to the test requirements, select the corresponding standard from the list of test standards in the operation interface, such as ASTM standard. Different standards have different requirements on testing process, loading speed, etc. Choosing the right standard can ensure the comparability and validity of the test results.

Setting the loading parameters: set the target force or displacement, and the loading speed. The loading speed can be adjusted flexibly within the range of 0.001 - 200mm/min according to the material properties and testing standards. For example, when testing brittle materials, the loading speed can be appropriately reduced to more accurately capture the mechanical data at the moment of fracture.

Sample Mounting

Sample Lifting: For heavy samples, the tester is equipped with a sample lifting aid to lift the sample to the test location. For example, when testing large structural components in the aerospace industry, specialized lifting equipment is used in conjunction with the tester's auxiliary devices to ensure that the samples are safely and accurately placed in place.

Clamping of samples: The samples are firmly clamped in the fixture by means of a quick positioning and clamping mechanism. Ensure that the sample is mounted in an accurate position to avoid eccentric force during the test, which may affect the accuracy of the test results. At the same time, be careful to avoid damage to the sample caused by the fixture.

Test Procedure

Start the test: Click the “Start” button on the operation interface and the tester starts to run automatically. Starting from the initialization of the device, the steps of sample clamping confirmation and loading test will be completed sequentially. During the loading process, the high-performance drive system of the tester provides stable loading force, so that the sample is subjected to uniform and continuous stretching.

Real-time monitoring: The operator can observe key data such as force, displacement, deformation and dynamic stress-strain curves in real time through the operator interface. If abnormal data is detected or a problem occurs during the test, the test can be stopped in a timely manner via the emergency stop button on the operator interface.

End of Test

Data Acquisition and Analysis: After the test is completed, the data acquisition and processing system of the tester automatically collects the force, displacement, time and other data during the test, and automatically calculates the tensile strength, yield strength, elongation and other mechanical property indexes of the material according to the built-in professional data processing software.

Generate report: Generate a detailed and standardized test report according to the report format pre-set by the user. The content of the report includes sample information, test standards, test data, calculation results and comparative analysis with standard values. Users can choose to print the report or save the electronic file according to their needs.

Clean up the equipment: Remove the samples after testing, clean up the fixture and the working area of the tester to prepare for the next test. At the same time, the tester is routinely checked to ensure that the equipment is in good condition.

Send Inquiry to This Supplier

You May Also Like

-

Universal Tensile Testing Machine for Packaging MaterialsUS$ 3999 - 9999MOQ: 1 Set

-

Automatic Universal Tensile Testing MachineUS$ 3999 - 9999MOQ: 1 Set

-

Universal Tensile Testing Machine for Laboratory TestingUS$ 3999 - 9999MOQ: 1 Set

-

Budget-Friendly Universal Tensile Testing Machine With Fast Delivery and After-Sales ServiceUS$ 3999 - 9999MOQ: 1 Set

-

Computerized Tensile Strength Test Machine - Automated Testing With Data Analysis SoftwareUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine With Customizable Options - Tailored to Your NeedsUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine for Quality Control Managers - Fast Results and Easy ReportingUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine With Custom Test Programs - Tailored to Your SpecificationsUS$ 3999 - 9999MOQ: 1 Set

-

Tensile Strength Test Machine With One-Button OperationUS$ 3999 - 9999MOQ: 1 Set

-

CE Certified Tensile Strength Test Machine - Meet European Safety StandardsUS$ 3999 - 9999MOQ: 1 Set