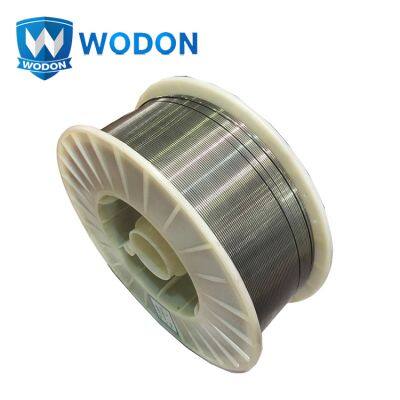

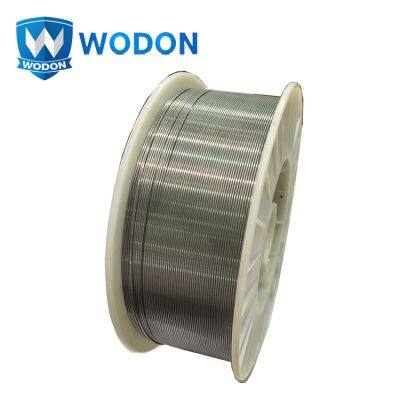

HB-YD788 High Wear-Resistant Hardfacing CCO Flux Cored Soldering Wire Metal & Metal Products

HB-YD788 high wear resistant hardfacing cco flux cored soldering wire

| HB-YD788 | ||||

| Diameter | 1.2mm;1.6mm; | |||

| Main ingredient | C | Cr | Si | Mn |

| Content | 3.0-4.5 | 24.0-30.0 | 0.50-1.50 | 0.50-2.50 |

| Hardness(HRC) | HRC 55-63 | |||

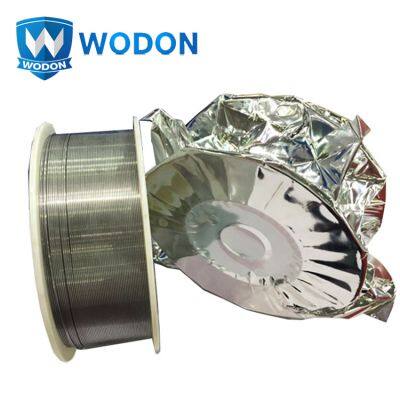

| Package | Package: 15KGS/Coil. No joints, weight can also be customized. | |||

| Instruction | HB-YD788 welding wire is a high wear resistant hardfacing wire, with hardness above 58 HRC, used for hardfacing of wear structural components. The wear resistantce is 20-30 times higher than carbon steel and the recommended overlay thickness is 20 mm or below. It is suitable for hardfacing of agricultural machinery, mining equipment which need good resistance for abrasive wear, such as hopper, shovel, mud pump and crusher. | |||

We develop our High quality self shielded wear resistant flux cored welding wire always according to plate's characteristics. This guarantees good performance regarding no clearing slag, low welding spatter, smooth surface, high welding efficiency and a transition coefficient above 0.9

HB-YD788 high wear resistant hardfacing cco flux cored soldering wire

Wear Resistant Flux Cored Welding Wire

| HB-YD788 | ||||

| Diameter | 1.2mm;1.6mm; | |||

| Main ingredient | C | Cr | Si | Mn |

| Content | 3.0-4.5 | 24.0-30.0 | 0.50-1.50 | 0.50-2.50 |

| Hardness(HRC) | HRC 55-63 | |||

| Package | Package: 15KGS/Coil. No joints, weight can also be customized. | |||

| Instruction | HB-YD788 welding wire is a high wear resistant hardfacing wire, with hardness above 58 HRC, used for hardfacing of wear structural components. The wear resistantce is 20-30 times higher than carbon steel and the recommended overlay thickness is 20 mm or below. It is suitable for hardfacing of agricultural machinery, mining equipment which need good resistance for abrasive wear, such as hopper, shovel, mud pump and crusher. | |||

Main Features

1. Chemical Composition: High carbon high chromium

2. Hardness: HRC58-65

3. Good Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.

4. Welding wire without any joints.

5. Production Capacity: 8000 tons per year

6. Short Delivery Time: Generally 7 days

7. We have many experienced professionals to research and develop welding wires according to customers' specified chemical compositions.

8. We can recommend proper welding wires and provide technical solutions based on working conditions.

9. On site inspection and third party inspection are available.

10. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

WD Wear Resistante Flux Core Welding Wires.

Squeezing Roller Hardfacing Wires.

Vertical Cement Mill Hardfacing Wires.

Gas Shielding Hardfacing Wires.

Coal Conveying Groove Hardfacing Wires.

Jiangsu Wodon Wear Resistant Material Co.,Ltd(CHINA WODON), located in the northern international shipping center TIANJIN. The company possesses many experienced senior engineers who provides professional solutions in high wear and abrasion resistant applications.

Our products have been widely applied to electric power, cement, mining, iron and steel etc. And with our product can increase the using life 3-4 times, reduce the cost of maintenance and save downtime. As well as the company have passed IOS9001, SGS, IAF.

The products are exported to South Korea, Mongolia, Peru, Australia etc.

Wodon flux cored welding wire's advantage

1. Wire feeding smooth, electric arc is stable, the diameter is even.

2. The welding wire has small spatter, little dust and more than 90% deposition efficiency.

3. Each barrel (package) welding wire is a whole welding wire, without joint. The welding process has no arcing phenomenon and improves production efficiency.

4. For the metal wear field, independently developed more than 100 kinds of flux cored wear resistant welding wire, can meet a variety of working conditions, parts of the wear-resistant requirements;

5. The matrix and the wear-resisting layer are the metallurgical combined, and the welding does not fall off after welding, and the stress is released evenly after the surfacing.

6. Provide qualification certificate, product specification, surfacing process, composition and hardness test report of surfacing layer, etc.

WODON wear plate and flux cored welding wires widely used for kinds of industry field: Dredging, Mining, Steelworks, Refineries, Cement, Timber, Power Generation Plants, Earthmoving, Coal Power Plant, etc.

The steel manufacturing industry, for example, requires wear protection for hoppers, conveyor liners quickly erode without hardfacing protection. And coke injection line elbows, alloy hopper, reverse fan box, dust handling system, high blast furnance coke screens, replaceable ID fan housing liners, wood pulp transfer line, log stacker fork liners, 1/2'' on 1'' mill feed chute liner, flat back elows.

As below is some examples of welding wire repairing :

Coal grinding roller surfacing welding wire; Vertical cement mill surfacing welding wire; Squeeze roller surfacing welding wire; Repair welding wire for middle trough of coal mine; Roller surfacing welding wire; Repair welding wire for steel slag grinding roller; Repair welding wire for star wheel; and other repair welding wire.

Various kinds of gas protection repair welding wires (repair all kinds of wear-resistant parts), high temperature resistant welding wire, grate bar and single tooth roller repair welding wire, impact resistant welding wire and various welding wires containing special elements (which can be customized as required)

Customer visit our factory

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL.

If you have another question, pls feel free to contact us as below:

Telephone: +86 156 2069 3942

Send Inquiry to This Supplier

You May Also Like

-

Wodon Wear Resistant Hardfacing Welding Wire With Flux CoredUS$ 3.56 - 3.56MOQ: 1 Kilogram

-

Cement Squeeze Roller Open Arc Wear Resistant Hardfacing Welding Wire 2.8mmUS$ 9.9 - 9.9MOQ: 1 Kilogram

-

Wodon Customizable Steel Flux Cored Welding Wire Manufacturer's Valve Surfacing Gas Shielding OEM SupportUS$ 4.02 - 4.02MOQ: 1 Kilogram

-

Chromium Carbide Hardfacing Flux Core WireUS$ 3.56 - 3.56MOQ: 1 Kilogram

-

250kg Drum Packing Hard Facing Flux Cored Wire Wear Plate Welding WireUS$ 4 - 4MOQ: 1 Kilogram

-

WD788 High Wear-Resistant Hardfacing CCO Flux Cored Soldering Wire Metal & Metal ProductsUS$ 5 - 5MOQ: 1 Kilogram

-

HRC58-63 1.2mm 1.6mm Flux Cored Welding Wire Mig Welding Wire for Metal Products for SaleUS$ 4 - 4MOQ: 1 Kilogram

-

Chinese Supplier Wodon Manufactured Tungsten Carbide Flux Cored Hardfacing Welding WireUS$ 7.27 - 7.27MOQ: 1 Kilogram

-

Chromium Carbide Flux Core Wire for Surface Welding Wear PlateUS$ 2.23 - 2.23MOQ: 1 Kilogram

-

High Temperature Resistant Flux Cored Hardfacing Wire for Welding Metal & Metal ProductsUS$ 9.9 - 9.9MOQ: 1 Kilogram