High Temperature Resistant Flux Cored Hardfacing Wire for Welding Metal & Metal Products

high temperature resistant welding flux cored hardfacing wire

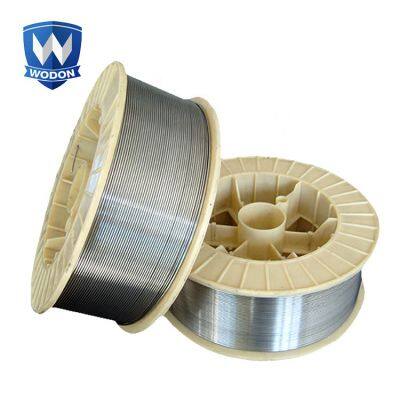

Wodon produce more than 100 kinds of Flux cored welding wires.

we can make:

*Wear plate welding wire

*Repairing welding wire

*Gas shielded welding wire

*Diameter: 1.2mm, 1.6mm, 2.0mm, 2.4mm,2.8mm, 3.2mm, 4.0mm etc

*Chemical Composition: C, Cr, Mn etc

*Hardness: HRC 58-65

| Categories | Introduction |

| Wear plate welding wire | Wire for single layer , double layers , and multiple layers |

| Repairing welding wire | Coal grinding roller hardracing welding wire, Cement mm nardfacing welding wire , Squeeze roller hardfacing welding wire , Coal mine middle trough repairing Repairing Welding Wire welding wire , Roller hardfacing welding wire , steel slag grinding , star wheel repairing welding wire , other various repairing welding wires |

| Gas shielded welding wire | Various gas shielding repairing welding wires ( repair all kinds of wear parts ) . Heat elding Wire resistance welding wire grate bar and single tooth roller repairing welding wire Gas Shielded Welding W impact resistant welding wire and various welding wires containing special elements ( customized as required ) |

| Instruction | 1. Smooth wire feeding, stable arc, uniform diameter; 2. Less spatter and Less smoke during welding above 9 0 % hardfacing efficiency; 3. Each drum packed with one whole piece of welding wires, without any joint, no broken arc phenomena during the welding to improve production efficiency; 4. Developing 108 kinds of flux cored wear resistant welding wire suited to metalwear resistant field which can satisfy the wear resistant requirements of many wear resistant parts under all kinds of working conditions instruction; 5. The base plate and the resistant overlay are metallurgical bonding, After welding . the wear resistant layer does not fall off because of uniform stress relief; 6. We can provide qualification certificate, product data sheet , hardfacing technology and hardfacing layer composition , hardness test report, etc. |

Jiangsu Wodon Wear Resistant Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu, a port hub city in North China. There are over 300 staffs, including 30 experienced R&D engineers. Our main products include: Chromium carbide overlay (CCO) wear plates, Flux cored hardfacing welding wires etc.

With independent intellectual property rights and a number of patents, we have a strong R&D and debugging team, which can provide customers with a streamlined service.

Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company’s technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

Chromium Carbide Overlay Wear Plate

Wodon wear plates are manufactured by welding one or multiple wear resistant layers on

a medium or low carbon steel base plate.The overlay alloy has a high amount of chromium

carbide hard particles which makes the plate have good wear and impact resistance.

Chromium Carbide Overlay Wear Plates

| Model | Characteristics | Hardness | Chemical Composition (%) | Operating Temperature | ||||||

| (HRC) | C | Cr | Mn | Si | Mo+Nb | Ni+V+W | Fe | |||

| WD-1000 | Common chromium carbide wear plate, suited for use in general wear applications involving low to medium impact | 58-65 | 3.0-5.0 | 17.0-27.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1100 | ||||||||||

| WD-1200 | High chromium carbide wear plates, Cr content is high up to above 40%,suited for use in severe abrasion applications, involving low to medium impact. | 58-65 | 3.0-6.0 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1500 | ||||||||||

| WD-1600 | Impact resistant wear plates, Independent R&D, suitable for medium to high impact. | 58-65 | 3.5-6.5 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | * | / | Bal. | <600℃ |

| WD-1800 | Heat resistant wear plate, heat resistance maximum up to 900℃ | 58-65 | 4.0-7.0 | 25.0-40.0 | / | / | * | * | Bal. | <900℃ |

| WD-NC100 | Crack free wear plate, mainly used as housing liner and side plate in steel mill | 50-55 | ||||||||

| Other series | Customized on request, special chemical element included for special abrasion fields | / | ||||||||

| Sheet size: 1400*3400mm 1400*3000mm 1500*3000mm 1400*3500mm 2000*3000mm 2100*3500mm Other on request | ||||||||||

| Base metal material: Q235, Q345 and so on. | ||||||||||

| Overlayer thickness: 3-50mm | ||||||||||

Picture of Submerged arc welding plate:

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions in our testing equipment.

45 minutes for each specimen

Results: The test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

As you can check on the picture, the carbide (Cr7C3) volume fraction on the microstructure is above 50%.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching up to 350Mpa in our tests.

d

Send Inquiry to This Supplier

You May Also Like

-

Customizable Vertical Mill Hardfacing Submerged Arc Welding Wire OEM/ODM Supported Manufactured by Expert ManufacturerUS$ 9.9 - 9.9MOQ: 1 Kilogram

-

Wear Resistant Flux Cored Soldering Submerged Arc Welding Manufacturer Vertical Mill Hardfacing WireUS$ 9.99 - 9.99MOQ: 1 Kilogram

-

Self-Shielded Flux Cored Wire for Hardfacing Wear Plate Submerged Arc Welding Metals & Metal ProductsUS$ 9.9 - 9.9MOQ: 1 Kilogram

-

Submerged Arc Hardfacing Wear Resistant Flux Cored WireUS$ 4.9 - 4.9MOQ: 1 Kilogram

-

Open Arc Welding China Manufacturer Wire Flux CoredUS$ 9.9 - 9.9MOQ: 1 Kilogram

-

Wodon Factory Hardfacing Mig Weld WireUS$ 4.02 - 4.02MOQ: 1 Kilogram

-

Wodon Factory Hardfacing Tungsten Welding WireUS$ 4.02 - 4.02MOQ: 1 Kilogram

-

Abrasion Resistant Flux Cored Mig Manganese Hard Facing Welding WireUS$ 5.9 - 5.9MOQ: 1 Kilogram

-

MIG Welding Wire Flux Cored Welding Wire Hardfacing Wire for Sale-Metals & Metal ProductsUS$ 4 - 4MOQ: 1 Kilogram

-

Hardfacing Wear Resistant Flux Cored Welding Wire With High HardnessUS$ 4 - 4MOQ: 1 Kilogram