Home > Products > Flux Core Welding Wire > Chromium carbide hardfacing flux core wire

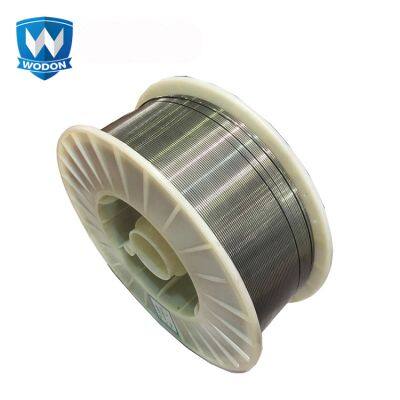

Chromium carbide hardfacing flux core wire

- 1000 Kilogram / Kilograms per Month

- T/T Credit Card

You May Like

-

250kg drum packing hard facing flux cored wire wear plate welding wire

-

WD788 High Wear-Resistant Hardfacing CCO Flux Cored Soldering Wire Metal & Metal Products

-

HRC58-63 1.2mm 1.6mm Flux Cored Welding Wire Mig Welding Wire for Metal Products for Sale

-

Chinese supplier Wodon manufactured Tungsten carbide flux cored hardfacing welding wire

-

chromium carbide flux core wire for surface welding wear plate

-

High Temperature Resistant Flux Cored Hardfacing Wire for Welding Metal & Metal Products

Product Description

Wodon chromium carbide hardfacing flux core wire

1. Type: flux cored welding wire for hardfacing/surface welding/cladding

2. Diameter: 1.2 mm, 1.6 mm, 4.0 mm, customized.

3. Standard: GB

4. Certification: ISO9001:2008, ISO14001:2004, OHSAA 18001-2007

Model | Diameter [mm] | Hardness [HRC] | Main Ingredient [%] | Main application and characteristics |

D688 | 1,2;1,6 | 50-58 | C: 2.5-5.0 Cr: 22.5-27.5 | Apply to a serious part of grinding wear surfacing, multi-layer welding. Surfacing layer thickness can be up 50 mm |

D788 | 50-60 | C: 3.0-4.5 Cr: 24-30 | Apply to a serious part of grinding wear surfacing welding, welding layer thickness control under 20 mm | |

D888 | 58-65 | C: 3.5-4.5 Cr: 24-27.5 | Apply to a serious parts of abrasive wear surfacing welding, welding layer thickness control under 10 mm | |

D788A | 50-60 | C: 3.0-4.5 Cr: 20-25 | Apply to a serious parts of abrasive wear surfacing, limited to single layer welding. | |

D788M | 60-66 | C: 3.0-4.5 Cr: 24-30 | Apply to a serious parts of abrasive wear surfacing | |

D688 Welding Rod | 4.0 | 50-58 | C: 2.5-5.0 Cr: 22.5-27.5 | Suitable for severe abrasive wear parts hardfacing welding, surfacing layer thickness control under 20 mm |

Flux cored welding wire production line

Flux cored welding wire

We develop our wear resistant flux cored welding wires always according to working condition. This guarantee good performance regarding no cleaning slag, low welding spatter, smooth surface, high welding efficiency.

The Filling rate of flux cored welding wire are about 50% with tolerance 1%, so that the chemical composition after welding are uniform and stable. We use advanced CNC system and regular test during the production, so guarantee the good welding result.

Portable Spectrum

We run regular test on our products according to company's policy based on ISO9001:2008

Rockwell Hardness tester

We are welding the welding wire on our experiment table, and cutting into small samples, so we can test the hardness and chemical composition.

Welding wire experiment table

In our labor can those small samples be tested seriously like Hardness, chemical composition, welding performance etc.

Factory

Now we are building a new branch factory in Jiangsu to improve our production capacity.

Workshop

Jiangsu Wodon Wear Resistant Material Co., Ltd is located in Jiangsu city, China's northern international shipping center. We are specialized in researching, developing and producing wear resistant products with many years experience in this field. We have more than 200 employees, with an annual output of 90000 square meters of wear plates and 9000 tons of welding consumables.

Warehouse

We have two warehouses and totally area 5000 square meters. Our logistic department are in charge of the distribution our products, so that our client can have the goods in shot time.

Warehouse

In our Warehouse are strictly managed, so our raw material and our products always good protected and are able to transport quickly and efficient.

With solid technical knowledge and R&D capacity, we have many experienced surface engineering professionals and often invite experts as advisers to provide solutions related to industrial abrasion. Our products have been widely applied in different industries like: power, cement, iron and steel, mining, port, coal, petroleum, chemical industry, railway, valves, sugar and shipbuilding industry. In addition, our company can offer professional solutions for the abrasion in different working conditions in order to reduce costs, increase lifetime of the work piece and extend equipment overhaul period, therefore building a very good reputation among our customers.

Packaging: 15 kg/spool, vacuum packing into carton, Steel Pallet, Plastic film, Customized

Packing Size: 1.15 m*0.58 m*0.88 m, 1.15 m*1.15 m*0.88 m, customized

Delivery Detail: Generally 7 days, if the goods are in stock. or it is 10~15 days if the goods are not in stock, it is according to quantity.

Shipment: Loading into 20 ft or 40 ft Container.

Quality certification

We are certified with the ISO9001:2008 and keep continuously improving our quality management system. We have strict procedures for raw materials, products inspection, production process, storage management and after sales service.

We are certified with the ISO1400:2004 and keep continuously improving our environmental management system. We use the electric boiler not the coal fired boiler to protect the environmental. We use the advanced dust removal and ventilation equipment to keep the air clean.

We are certified with the OHSAS18001-2007 and keep continuously improving our occupational health and safety management system. Our every technical staff wears filter mask, protective clothing and gloves and welding goggles.

1. Good Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.

2. welding wire without any joints, vacuum packing into carton,Quality warranty period longer than one year.

3. Production Capacity: 9000 tons per year

4. Short Delivery Time: Generally 7 days

5. We have many experienced professionals to research and develop welding wires according to customers' specified chemical compositions.

6. We can recommend proper welding wires and provide technical solutions based on working conditions.

7. on site inspection and third party inspection are available.

8. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

After-sales commitment

Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Quality Control

We have our own inspection technology department. The team are made of many experienced technical with material science bachelor degree and the team leader are with master degree. They are very professional to inspect and run test on the products. According to our company's policy each our product have a special number, so we can trace back to anywhere, if there are quality problems.

We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.

Q: Are you trading company or manufacturer ?

A: We are manufacturer with more than 3 factory, our own sales department and Inspection technology department.

Q: How long is your delivery time?

A: Generally it is 7 days if the goods are in stock. or it is 10~15 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A: 30% T/T in advance ,balance against copy of BL.

If you have another question, pls feel free to contact us as below:

Company Profile

Jiangsu Wodon Wear Resistant New Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu. There are over 500 staff, including 60 experienced R&D engineers. Our main products include: chromium carbide overlay (CCO) wear plates, flux cored hardfacing welding wires, etc. With independent intellectual property rights and a number of patents, it has a strong R&D and debugging team, which can provide customers with a streamlined service.Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company's technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

Contact Us

- Jiangsu Wodon Wear Resistant New Material Co., Ltd.

- Contact namezhang Chat Now

- Addresshongze, Huaian, Jiangsu

Product Categories

| Ungrouped | CCO Wear Plate | Flux Core Welding Wire | Wear Components |

| Wear Pipes and Fittings | Wear parts |

New Products

-

Customizable OEM/ODM Abrasive Soldering Flux Flux Cored Welding Wire for Aluminum & Welding Alloys

-

MIG Flux Core Open Arc Tungsten Carbide Welding Wire Customizable Diameter ER70S-6 Model Tin Copper Metal Soldering ODM OEM

-

Customizable OEM/ODM Wear-Resistant Soldering & Surfacing Flux Cored Welding Wires

-

OEM/ODM Customizable ER70S-6 Flux Cored Wire for MIG Welding Wear & Impact Resistant Copper Steel Co2 Alloy Plastic Materials\

-

Wodon Customizable Diameter Flux Cored Hardfacing Manganese Welding Wire Abrasion Resistant

-

Customizable Vertical Mill Hardfacing Submerged Arc Welding Wire OEM/ODM Supported Manufactured by Expert Manufacturer

-

wear resistant flux cored soldering submerged arc welding manufacturer vertical mill hardfacing wire

-

Self-Shielded Flux Cored Wire for Hardfacing Wear Plate Submerged Arc Welding Metals & Metal Products

-

submerged arc hardfacing wear resistant flux cored wire

-

open arc welding china manufacturer wire flux cored

-

Wodon Factory hardfacing mig weld wire

-

Wodon Factory hardfacing tungsten welding wire

-

abrasion resistant flux cored mig manganese hard facing welding wire

-

MIG Welding Wire Flux Cored Welding Wire Hardfacing Wire for Sale-Metals & Metal Products

-

Hardfacing wear resistant flux cored welding wire with high hardness

-

HB-YD688 15KG package co2 mig wear resistant welding wire for repair bin

-

Wodon high chromium carbide hardfacing flux cored welding wire

-

Overlay Hardfacing Flux Cored Welding Wire for Cement Squeeze Roller & Steel Mill Roller Metal & Metal Products Repairing

-

China plant submerged open flux cored arc welding wire for hardfacing repairing coal mill roller

-

HB-YD788 High C Cr Wear Resistant Plate Hardfacing CCO Flux Cored Welding Wire for Medium to High Impact-OEM Customizable

-

High Hardness Wear-Resistant Plate for Coal Mining Mill Roller Repair Flux Cored Welding Wire Hardfacing Metal & Metal Products

-

High CCO Flux Cored Welding Wire for Wear Plate Hardfacing & Gas Shielded Welding Metal & Metal Products

-

overlay hardfacing flux cored repairing welding wire mig carbide chrome cement squeeze roller and steel mill roller

-

Wodon ferro chromium flux cored welding wire with repairing wear parts

Popular Searches

- steel wire

- waved steel fiber

- wire rope

- Wire Rod

- Galvanized Steel Wire Rope

- Stainless Steel Wire Rope

- high strength

- Alloy Wire

- Spring Steel

- steel wire rod

- Galvanized Steel Wire

- Gi Wire

- Steel Strand Wire

- spring wire

- steel wire rope

- Wire Rod Steel

- Spring Steel Wire

- Carbon Spring Steel Wire

- radial tire cord

- steel strand

- Stainless Steel Wire

- High Carbon Steel Wire

- Low Carbon Steel Wire

- Flat Steel Wire

- winch cable

- zinc coated wire

- Gi Binding Wire

- throttle cable ends

- q195

- low carbon steel

Find Similar Products By Category

- Metallurgy, Mineral & Energy > Steel & Products > Steel Wire

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

zhang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

zhang

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile