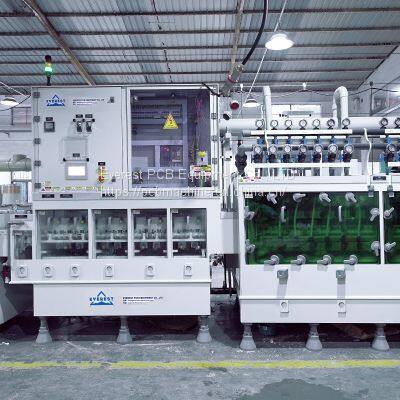

Everest PCB Dry Film Developing Machine Easy to Operate Film Developer

Details Images

Products Description

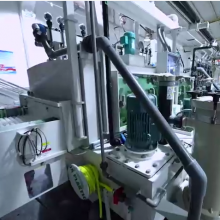

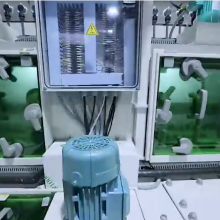

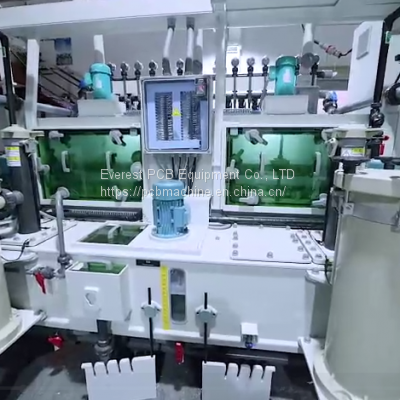

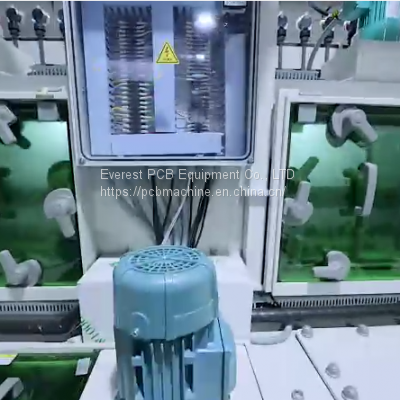

Pressure Adjust System

Temperature control system

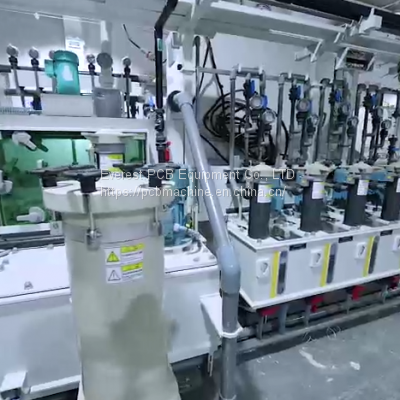

Net Filter System

2.Uses PCB technology with double oscillatory frame to get higher precision

3.The body is made of PP or PVC,which is heat-resistant, corrosion-resistant and strain-resistant.

4.Adopted high pressure system,so the praying is more uniform

5.The speed can be adjusted for your different requirements.

6.Built in thermostat and can work for a long time.

7.Heating tube and cooling tube used titanium materials with good corrosion resistance.

and the best temperature could be ensure by automatic heating and cooling device.

8.Simple operation, it's very suitable for mass production.

9.Non-standard sizes can be customized according to different business requirement

Timely service,life-long maintenance.

Free training for installation and operation of products.

Provide main component for replacement when you send back the problematical ones.

Our services

Company Profile

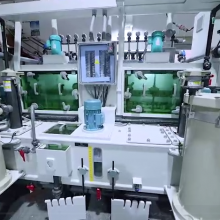

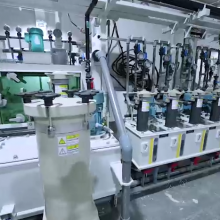

Customer Photos

Product packaging

Send Inquiry to This Supplier

You May Also Like

-

Big Stainless Steel Elevator Pattern Plate Etching MachineUS$ 5000 - 6000MOQ: 1 Set

-

PCB Dry Film Stripping MachineUS$ 25000 - 28000MOQ: 1 Set

-

PCB HASL Pre Treatment of Hot Air Solder LevelingUS$ 27000 - 35000MOQ: 1 Set

-

Modular Type Automatic PCB Film Stripping MachineUS$ 25000 - 28000MOQ: 1 Set

-

Gold Plating Line Electroplating EquipmentUS$ 200000 - 1000000MOQ: 1 Set

-

PCB Pattern Plating Panel Plating LineUS$ 200000 - 1000000MOQ: 1 Set

-

CNC Routing & Drilling Machine for PCB Board With High Speed 3 SpindlesUS$ 50000 - 60000MOQ: 1 Set

-

SMT Stencil Cutting Machine for Metal Sheet High Accuracy Fiber Laser CutterUS$ 50000 - 60000MOQ: 1 Set

-

High Efficient Metal Punching Machine With Accurate PositioningUS$ 7000 - 9000MOQ: 1 Set

-

6 Spindles CNC Routing & Drilling Machine for PCB BoardUS$ 50000 - 60000MOQ: 1 Set