PP/PE /PC Plastic Hollow Plate/Board/Sheet Extruder Machine Production Line

Product Introduction

Polypropylene corrugated board (PP corrugated board) is one of the packaging material which is most flexibility and widely used.

The main component of the PP corrugated board is polypropylene, which is a highly pure hydrocarbon, non-toxic, anti-chemical, combustible, no hazardous substances and environment friendly.

Our own PP hollow board production line for providing the best packaging solution according to different situations.

The material of the PP corrugated sheet can be divided into 3 types (recycled, mixed and 100% virgin material) according to the ratio of the material. They can be differentiates by comparing their smoothness, brightness of color and hardness. The 100% virgin material is the best of smoothness, brightness of color and hardness, then mixed, last the recycled.

Application

PC hollow sheet is widely used in construction sunroof in buildings/halls/shopping center/stadium/public places of entertainment and public facility; Ring shield of bus station/garages/pergolas/corridors; noise barriers for highways and urban elevated road.

Machine List

| NO | Equipment |

| 1 | Single Screw Extruder |

| 2 | Screen Changers |

| 3 | Mould |

| 4 | Vaccum Sizing Cooling Platform |

| 5 | Edge Cutting Device |

| 6 | The First Tractor |

| 7 | Infrared Alignment Oven |

| 8 | Powerful Forced-air Cooling Device |

| 9 | The Second Tractor |

| 10 | The Cutter |

| 11 | The Stacker |

| 12 | Electric Control System |

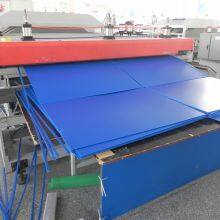

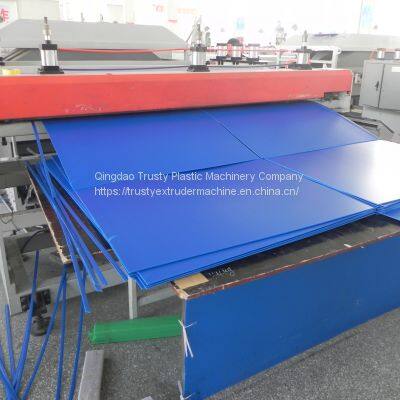

Detailed Photos

|  |

|  |

|  |

Technical Parameter

| PP/PE Hollow Sheet Extrusion Line Technical Data | PC Hollow Sheet Extrusion Line Technical Data | ||

| Extruder model | SJ-120,SJ-100 | Extruder model | SJ-120, SJ-45 |

| Sheet width | 2100mm, 1220mm | Sheet width | 2100mm |

| Sheet thickness | 2-8mm, 2-8mm | Sheet thickness | 4-40mm |

| Max capacity | 350kg/h,200kg/h | Max capacity | 450kg/h |

| Main motor power | 132kw | Main motor power | 132kw |

Qingdao Trusty Plastic Machinery Company is a professional company specialize in designing and manufacturing plastic extrusion machine. We introduced and absorbed the advanced plastic processing technology, which can provide the technology and machinery one-step service.

Our company's main products are: PVC door and window profile production line, WPC wood-plastic profile production line, PVC wall panel production line, PVC/PE/PPR pipe production line, crust-foamed board production line, PE/PP/PC hollow sheet production line, PVC roof tile production line and PET packing belt production line, etc. According to customers' needs, to achieve diversified processing customization.

Send Inquiry to This Supplier

You May Also Like

-

Factory Price Single Screw Mbbr Filter Media Production LineUS$ 36000 - 66000MOQ: 1 Set

-

COD HDPE Cable Communication Protect Pipe Production LineUS$ 47000 - 73000MOQ: 1 Set

-

Recycled Single Screw Mpp Pipe Extruder Machine Production LineUS$ 31000 - 46000MOQ: 1 Set

-

UPVC/PVC/WPC/ Ceiling/Wall Panel Twin Extruder Production LineUS$ 32000 - 45000MOQ: 1 Set

-

SRL Series Plastic Mixer MachineUS$ 5000 - 15000MOQ: 1 Set

-

High Efficency Energy Saving PE Pipe Extrusion MachineUS$ 45000 - 68000MOQ: 1 Set

-

Plastic Woven Bag PP Flat Yarn Filament Extruder LineUS$ 63000 - 87000MOQ: 1 Set

-

PP PE PET Rope Monofilament Yarn Manufacturing Extrusion MachineUS$ 65000 - 87000MOQ: 1 Set

-

PE WPC Profile Extruder Machine Production LineUS$ 32000 - 45000MOQ: 1 Set

-

Plastic PVC Pipe Making Extruder Production LineUS$ 41000 - 69000MOQ: 1 Set