Home > Products > Screening machine > Portable Mobile Linear Cement Metallurgy Circular Vibrating Screen For Mining Quarry Crushing Plant

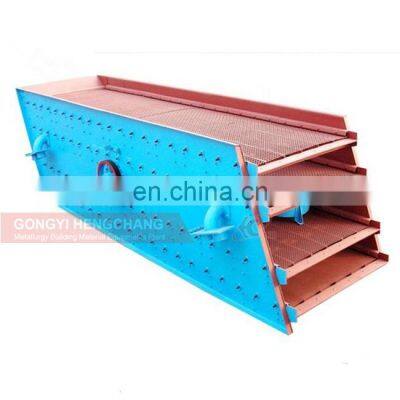

Portable Mobile Linear Cement Metallurgy Circular Vibrating Screen For Mining Quarry Crushing Plant

Negotiable

1 (Min.Order)

- 1000 per Month

- T/T Credit Card

You May Like

-

Multi-Layers gravel rocks vibrating sieve shaker

-

New Design Energy saving Stainless Steel Trommel Rotary Screen For Sale

-

Biomass wood chips sawdust powder rotating drum screen

-

gold ore vibrating screen mining screening machine

-

Rock trommel screen washer for solid waste separation

-

Multi-Layer Carbon Steel Aggregate Vibrating Screen Quarry Sand Sieve

Product Description

Products Description

Circular vibrating screen is a multi-layer, high-efficiency new vibrating screen. The circular vibrating screen adopts a cylindrical eccentric shaft exciter and an eccentric block to adjust the amplitude. The material sieve has a long flowing line and many screening specifications. It has a reliable structure, strong excitation force, high screening efficiency, low vibration noise, strong and durable, maintenance Convenient and safe to use, the round vibrating screen is widely used in product classification in mining, building materials, transportation, energy, chemical and other industries. According to the material products and user requirements, high manganese steel woven screen, punching screen plate and rubber screen plate can be used. All kinds of screen plates can meet the different requirements of the screening effect. This series of circular vibrating screens is seat-mounted. The inclination of the screen surface can be adjusted by changing the height of the spring support.

Details Images

Working principle

The crushed material group with different particle sizes passes through the single-layer or multi-layer sieve with uniformly distributed holes multiple times, and the process of dividing into several different levels becomes sieving. The particles larger than the screen hole are left on the screen surface, which is called the sieve on the screen surface, and the particles smaller than the screen hole penetrate the screen hole, which is called the sieve on the screen surface. The actual sieving process is: after a large amount of mixed materials with different particle sizes and mixed thicknesses enter the sieve surface, only a part of the particles are in contact with the sieve surface. Due to the vibration of the sieve box, the material layer on the sieve is loosened, so that the large particles already exist The gap is further expanded, and small particles take the opportunity to pass through the gap and transfer to the lower layer or transport aircraft. Due to the small gaps between small particles, large particles cannot pass through, so the original disordered particle group was separated, that is, the particles were stratified according to the size of the particles, forming the arrangement rule of small particles below and coarse particles above. The fine particles that reach the sieve surface are smaller than the sieve holes, and finally the coarse and fine particles are separated to complete the screening process. However, there is no sufficient separation. When sieving, a part of the sieve is usually left on the sieve. When fine particles pass through the sieve, although the particles are smaller than the sieve pores, they are different in the degree of difficulty in sieve penetration. The particles with similar material and sieve pore size are more difficult to pass through the sieve, and the gap between the particles through the lower layer of the sieve is more difficult.

Product Characteristics

(1) Large processing capacity and high screening efficiency.

(2) The vibrator adopts bearing thin oil lubrication and external block eccentric structure. It has the characteristics of large excitation force, low bearing load, low temperature and low noise. (The bearing temperature rise is less than 35 °).

(3) The overall disassembly and assembly of the vibrator is convenient for maintenance and replacement, which greatly shortens the inspection cycle. (It only takes 1 to 2 hours to replace the vibrator).

(4) The side plate of the screen machine adopts the whole plate cold work, no welding, high strength and long service life. The connection between the beam and the side plate adopts torsion shear high-strength bolt connection, no welding, and the beam is easy to replace.

(5) The screen machine uses rubber springs to reduce vibration. Compared with metal springs, it has the advantages of low noise, long service life, stable over-common vibration area, and small dynamic load at each pivot of the screen machine.

(6) The flexible coupling is used to connect the motor and the exciter, which has the advantages of long service life and small impact on the motor.

Product Paramenters

Model | Screen Deck | Installation Slope(°) | Screen Size(m2) | Screen Pore Size(mm) | Feeding Size(mm) | Capacity (t/h) | Motor Power (kw) | Weight (kg) |

YK1230 | 1 | 15 | 3.6 | 4-50 | ≤300 | 10-75 | 5.5 | 1468 |

2YK1230 | 2 | 15 | 3.6 | 4-50 | ≤300 | 13-78 | 5.5 | 2253 |

3YK1230 | 3 | 15 | 3.6 | 4-50 | ≤300 | 15-80 | 7.5 | 2978 |

4YK1230 | 4 | 15 | 3.6 | 4-50 | ≤300 | 17-90 | 7.5 | 3892 |

YK1235 | 1 | 15 | 4.2 | 4-50 | ≤300 | 20-150 | 5.5 | 1729 |

2YK1235 | 2 | 15 | 4.2 | 4-50 | ≤300 | 20-150 | 5.5 | 2474 |

3YK1235 | 3 | 15 | 4.2 | 4-50 | ≤300 | 22-150 | 7.5 | 3158 |

4YK1235 | 4 | 15 | 4.2 | 4-50 | ≤300 | 22-150 | 7.5 | 4160 |

2YK1545 | 2 | 20 | 6.75 | 5-50 | ≤300 | 22-150 | 11 | 5308 |

3YK1545 | 3 | 20 | 6.75 | 5-50 | ≤300 | 50-180 | 15 | 5915 |

4YK1545 | 4 | 20 | 6.75 | 5-50 | ≤300 | 50-180 | 15 | 7126 |

2YK1554 | 2 | 20 | 8.1 | 5-50 | ≤300 | 50-200 | 15 | 5284 |

3YK1554 | 3 | 20 | 8.1 | 5-50 | ≤300 | 56-200 | 15 | 6186 |

4YK1554 | 4 | 20 | 8.1 | 5-50 | ≤300 | 56-250 | 18.5 | 7284 |

2YK1854 | 2 | 20 | 9.72 | 5-80 | ≤300 | 56-200 | 18.5 | 5826 |

3YK1854 | 3 | 20 | 9.72 | 5-80 | ≤300 | 56-300 | 18.5 | 7368 |

4YK1854 | 4 | 20 | 9.72 | 5-80 | ≤300 | 56-300 | 22 | 8281 |

2YK1860 | 2 | 20 | 10.8 | 5-80 | ≤300 | 60-400 | 22 | 6195 |

3YK1860 | 3 | 20 | 10.8 | 5-80 | ≤300 | 80-400 | 22 | 7613 |

4YK1860 | 4 | 20 | 10.8 | 5-80 | ≤300 | 90-500 | 30 | 8650 |

2YK2160 | 2 | 20 | 12.6 | 5-80 | ≤300 | 100-720 | 22 | 6856 |

3YK2160 | 3 | 20 | 12.6 | 5-80 | ≤300 | 100-720 | 30 | 9112 |

4YK2160 | 4 | 20 | 12.6 | 5-80 | ≤300 | 100-720 | 30 | 10405 |

2YK2460 | 2 | 20 | 14.4 | 5-80 | ≤300 | 130-750 | 30 | 8503 |

3YK2460 | 3 | 20 | 14.4 | 5-80 | ≤300 | 130-750 | 37 | 10411 |

4YK2460 | 4 | 20 | 14.4 | 5-80 | ≤300 | 130-750 | 45 | 12068 |

Company Profile

Contact Us

- Gongyi Hengchang Metallurgical Building Material Equipments Plant

Product Categories

New Products

-

40-60tph Mobile Screening Plant Sand Mobile Vibrating Screen Separator For Sale

-

2020 Good Price Sale High Efficiency Stone Circular Vibrating Feeder For Mining

-

small mobile diesel engine gold mining trommel washing machine

-

Hot Sale Scale 5-10t/H Gold Ore Processing Plant Small Rotary Heavy Duty Rock Mobile Trommel Screen

-

rotary drum compost / manure / sand gravel trommel screen with brush

-

High efficiency sand/stone vibrating sieve machine for sale

-

Good Performance Multi-4 decks Vibrating Screen Vibrating Washing Screens Separator Vibrating Screening Machine Plant

-

mini gold trommel for sale

-

40-60tph Mobile Screening Plant Sand Mobile Vibrating Screen Separator For Sale

-

linear vibrating feeder for copper gold ore processing plant

-

High quality mineral ore linear vibrating feeder

-

GZD 800 X 3000 iron copper ore vibration feeder

-

Hot sale constant feeder--box rationing feeder for Industrial use

-

Gold mining feeder Grizzly Electromagnetic Vibrating Feeder Machine for Mining feeder

-

Electromagnetic Mining Ore Vibration Feeder Controller

-

Limestone electromagnetic vibrating grizzly screen feeder

-

Good quality quarry processing line stone vibratory feeder

-

China Manufacturer 2020 Hot Sale Feeding Machine Vibrating Feeder With Good Price

-

GZD series big capacity electric vibrating feeder used for evenly feeding

-

New design hot selling mineral ore/stone vibrating feeder

-

Small food grade vertical bucket elevator for sale

-

650mm/800mm width belt conveyor

-

Factory direct sale moving belt conveyor for mining production line with customized length and width

-

Direct supplier sawdust powder rubber belt conveyor

Popular Searches

- Vibrating Screen

- Experiment Equipment

- bouncing

- sifter

- starch sugar

- stainless steel sieve

- shakers

- overall screen

- vibrating sieve

- Sieving Machine

- Sieve Machine

- jumping device

- fine powder machine

- Vibrating Screen Machine

- shake belt

- Vibrating Machine

- laboratory test sieve

- stainless steel test sieve

- test sieving equipment

- test sieving shaker

- testing sieve

- sieve shaker

- sieve screen

- testing equipment sieve

- Vibration Sieve

- Analysis Equipment Sieve

- Sifter Machine Shaker Sieve

- Test Vibrating Sieve

- Sieve Shaker Machine

- Sieve Shaker Equipment

Recommended Products

- Yosion Technology YX-ZS200 Sieve Shaker;Standard Sieve Shaker;Sample Separation

- Vibrating Screen

- TBK 2203 2205 Laser Welding Machine for Chip Desoldering Glue Removal

- Xwitzeal X1 20W Laser Machine has iPhone 8-16 Pro Max back glass removal

- Shaftless drum screen: a new choice for efficient screening

- High-efficiency and energy-saving sand screening machine, environmentally friendly and practical, is a wise choice for your sand field!

- High-end mud and stone separation equipment: excellent quality, helping the green development of mining

- MECHANIC GAN-03 GAN-16 Fenix 16-Inch Screen Bubble Removal Machine for Mobile Phone iPad Tablet Curved and Straight Screen Refurbishment

- Sand screening machine: high efficiency and energy saving to improve the quality and purity of sand and stone

- Mud-stone separator: reduce labor costs and improve production efficiency

- Mobile stone screening machine: flexible operation, efficient screening of stone materials

- Mobile sand screening machine, flexible and efficient, professional screening

Find Similar Products By Category

- Machinery > Energy & Mineral Equipment > Mining Machinery > Vibrating Screen

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now

Gongyi Hengchang Metallurgical Building Material Equipments Plant

AIBot OnlineThis conversation is AI-generated. Contact manufacturer before transaction to confirm info.

-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile