Gypsum Cornice Making Machine / Molds for Gypsum Cornice Molding / Gypsum Cornice Mould Making

gypsum cornice making machine

| Gauranteed service from Yurui Group |

1. Promise the most competitive price base on the same quality level 3. Supply the perfect service on machines, production, marketing, 24 hours online consultant 4. Gaurantee machines quality for 1 year after installation 5. Control the delivery time within your expectation |

| General working process of machines making gypsum cornice |

1. Dosing system, to get the qualified gypsum powder slurry 2. Automatic weighing system, and screw conveyer 3. Raw material liquid Feeding system, to discharge liquid raw materials onto forming mold 4. Scrape the gypsum cornice automatically, to make sure smooth surface and good shape 5. Mold-separating, to get formed gypsum cornice out of mold 6. Drying, to hang gypsum cornice to dry naturally 7. Discharging and packing system |

|

| Equipment data of gypsum cornice machine |

1. Capacity: 3000 unit/day; 6000 unit/day; 8000 unit/day 2 .Automatic production line 3. Land area: warehouse design can be adjustable according to clients' situation 4. Raw material: construction gypsum powder, mesh, fiber-glass, water, addtives |

|

| Equipment of gypsum cornice machine |

Silo and mixing machine, with China advanced core-technology, to guarantee that, continuous discharging raw material slurry without any stop and block. Slurry with unique formula, to make sure high strength, good finished gypsum cornice quality

Equipped with 10 tons of powder silo, storage saving more labors. Live longer than other products , lower cost. |

|

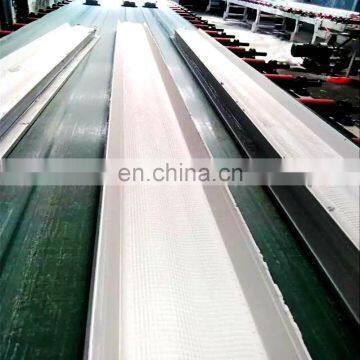

| Forming line of gypsum cornice |

Accurate CNC process of all machine parts, easy to guarantee flat level of whole forming convey line, easy to maintenance and adjust. PLC automatic control, and Germany soundless air compressor, to make sure no noise, easy working environment, and long-term machine service life. |

|

|

| Mold types of gypsum cornice |

Mainly two types of mold, one is plain or common mold, another one is flower designed mold. All are made of alloy material, make sure cornice shape complete and stereo and beautiful. machine service life is more than 20,000times, can ignore mould consumption.(manual machine FRP mould service life is just 2000 times, with loss of RMB0.02) |

|

|

|

| Raw materials used for gypsum cornice |

Good quality of raw material is very important for making qualified gypsum cornice. We are able to guarantee you are you using the qualified raw materials |

|

| Drying naturally of gypsum cornice |

Because of gypsum itself characters, no need to machinery drying, naturally drying is ok for usual weather condition. But for example, in China, Winter will need longer time than in Summer time. |

|

| Other production line from Yurui Group |

1. Gypsum powder production line / machine 2. Gypsum board production line / machine 3. PVC Gypsum ceiling tile production line / machine 4. Gypsum block production line / machine 5. MGO board production line / machine |

Send Inquiry to This Supplier

You May Also Like

-

Plasterboard Manufacturing Machines/ Gypsum Board Production LineNegotiableMOQ: 1

-

SBS &APP Waterproof Membrane Production LineUS$ 96,000 - 583,000MOQ: 1 Set

-

China Pe200x300 Smallest Jaw CrusherNegotiableMOQ: 1 Set

-

Precast Concrete Wall Machine Manufacturing Sandwich Panel MachineUS$ 150,000 - 350,000MOQ: 1 Set

-

High Precision Aluminium and PVC Glass Batten Glazing Bead SawUS$ 600 - 1,100MOQ: 1 Set

-

Precast Concrete Hollow Core Wall Panel MachineryNegotiableMOQ: 1 Set

-

XQY3-10 Semi Automatic Cement Block Making MachineNegotiableMOQ: 1 Set

-

Quick Lime Production Plant for SaleUS$ 4,000,000 - 5,000,000MOQ: 1 Set

-

Building Material Precast Wall Panel MachineryUS$ 16,000 - 18,000MOQ: 1 Set

-

Good Quality TILE BACKER BOARD EXTRUSION LINEUS$ 1,000 - 50,000MOQ: 1 Set

Recommended Categories

Explore top categories and find suppliers for your specific needs-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.