Fully Automatic Environment Friendly Gypsum Block Production Line

We have rich experience in gypsum board production line field. Our general engineer has over 20years experience, other main engineers all have over 10years experience, proficient in the newest gypsum board production line design and manufacturing. With over 100 projects in domestic and abroad markets, we can ensure you a successful project.

Equipment advantages

1.Fine workmanship, high precision, reliable quality, beautiful appearance.

2.Accurate dosing raw material, foam foam standing is our patent, produce the board of light weight, good toughness and cost savings,

3.The cutting machine uses dual-serve motor, only1 mm gap between cutting saw, saving cost .

4.We adopt the hot air irculation, drying room temperature is uniform, the board has high strength and is not fragile.

5.High electrical automation degree, low failure rate, less workers.

Dosing System

Application :used to dosing and mixing suitable raw material to get gypsum powder

Paper supply system

Application :Supply paper to the gypsum board

Forming and solidification system

Application :to form the semi-gypsum board from gypsum powder slurry

Forming speed :6m/min,gypsum board forming special belt(ring type ,no joint)

Automatic cutting system

Application: automatic cut the solidified gypsum board to setted size

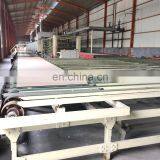

Transit System

Application:used to horizontally transport the cutted board to the distributor, other unqualified board will be send out of the production line

Distribution System

Application :used to transport wet gypsum board to each layer of the drying machine with the control of PLC

Drying system

Application :Used to dry the forming board

Discharging board and finished board system

Used to convey gypsum board and cut edge to the needed size then edging tapping and stacking

Send Inquiry to This Supplier

You May Also Like

-

Fully Automatic 3 Ply Nonwoven Fabric Disposable Medical Facemask Facial Surgical Face Masks Making Machine Production LineNegotiableMOQ: 1

-

Factory Manufacture Melt Blown Fabric MachineUS$ 72,000 - 72,000MOQ: 1 Set

-

Low Cost High Quality Slitting Nonwoven Fabric Cutting MachineUS$ 11,000 - 14,000MOQ: 1 Set

-

Automated Surgical Gown Making MachineUS$ 20,000 - 20,000MOQ: 1 Set

-

Machine Spot Welding Equipment Face Mask Welding Elastic Mask MachineUS$ 10,000 - 90,000MOQ: 1 Set

-

Dongguan Disposable Medical Outside Ear Loop Anti-Dust Face N95 M-a-s-k Making MachineUS$ 200,000 - 350,000MOQ: 1 Set

-

Plain Red Velvet Flock Fabric for Packaging Gift Box Fabric Material , Flocking FabricsNegotiableMOQ: 1 Set

-

Needle Machine /needle DetectorUS$ 0.0001 - 0.0001MOQ: 1 Set

-

2L Automatic Adjustable Time Centralized Lubricant Felting MachinesUS$ 50 - 150MOQ: 1 Piece

-

Regenerated Cotton Machine EquipmentUS$ 5,500 - 8,500MOQ: 1 Set

Recommended Categories

Explore top categories and find suppliers for your specific needs-

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

sales

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.