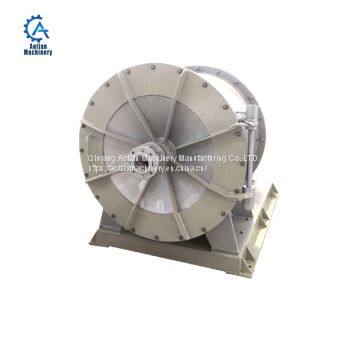

Machinery Fiber Separator Paper Pulp Makin Effect Fiber Separator

waste paper recycling fiber separator waste paper recycling fiber separator waste paper recycling fiber separator waste paper recycling fiber separator waste paper recycling fiber separator

Machinery Fiber Separator Paper Pulp Makin effect fiber separator

Dear Sir/Madam,

Thanks for your interest in our paper pulp fiber separator.

Welcome to contact with us!

In order to recommend proper machine and make detailed technical proposal and exact offer for you as soon possible,could you please tell us the following technical parameters:

| 1 | What's your required capacity ? |

| 2 | What's the inlet consistency ? |

| 3 | What's the diameter of screen hole ? |

| 4 | What's the power of motor ? |

Accept custom, only need to provide related parameters, we will design for you to make you satisfied with the machine.

Just contect me,Nancy, nancy AT

Qinyang Aotian Waste paper recycling fiber separator for paper pulp making in paper mill

Product overview of waste paper recycling fiber separator :

Pulp machine fiber separator machine is a combination of one sealed horizontal hydrapulper and a light & heavy impurity remover. It adopts drum and turbo structure so has higher efficiency.With compact structure,high efficiency,it has functions such as pulp beating,impurity removing ,coarse screening etc,thus simplifies the process of dealing with wasted paper greatly, and reduces the energy consumption.

Working principle of paper pulp fiber separator :

Paper Pulp get into the cylinder shaped cabinet with a tangent track and revolve in high speed with the impulse of pressure difference and revolving cutter. Then in the effect of hydraulic shear force , friction of fibers and the beating of blades, the pulp is defibered.

The pressure difference between sieve plates and drive impulse of cutters make The defibered pulp go through the screen holes on sieve plates and go out from accept outlet. The pulp which can not go through sieve plates revolve rapidly in the cabinet and generate strong centrifugal force, which together with the difference of proportion make the heavy impurities , fiber and light impurities radially stratified. Heavy impurity, fiber and light impurities at the same time move to the section far away from sieve plates with the push of cutter blades. Heavy impurities move along the inside wall of cabinet to tangent outlet and go into heavy impurity cleaner.

After the cleaning of heavy impurity, pulp will go out from cleaner regularly and get into fiber separator again from pulp inlet; Light impurities have small proportion ,they are concentrated in the central part and go out continuously from central outlet. when pulp move to end cover, it will flow back to cutter and go through sieve plates again.

Main Technical Parameters of paper pulp fiber separator :

Product name | Fiber separator |

Type | AT-ZDF2 |

Production capacity(T/D) | 30-40 |

Impeller diameter(mm) | 450 |

Screen hole specification(mm) | Ø2.5-5 |

Concentration of inlet pulp(%) | 2.5-4.5 |

Pulping pressure(Mpa) | 0.2-0.3 |

Power(KW) | 45 |

Accept customization, only need to provide related parameters, we will design for you to make you satisfied with the machine.

Part 1:

1)Low MOQ: It can meet your low qty demand very well.

2)Good Service: We treat clients business as our own business.

3)Good Quality:We have strict QC quality control system .Good reputation in the market.

4)Fast & Cheap Delivery: We have big discount from shipping forwarder (Long Contract).

Part 2:

1. We have rich experience in this industy(our company was established in 1996);

2. We are the factory outlet ,can give you a cheaper price ;

3. For the machine,we have complete paper machinery with top quality.

1.Help customers find the right product by professional technology and business consultation

2.Provide plans of the machines installation freely

3.Make customized products according to the clients requirements

4.Online for 24 hours

1.Fast and saft delivery

2.Assist our clients to bulid the equipment

3.Train the first-line operators on site

4.Regularly visit clients to solve production problems

5.Online for 24 hours

Brief Introduction:

Our company was founded in 1985,according to the modern enterprise mechanism into a large-scale standardized joint-stock enterprises,with 278 workers,including 23 engineers and technicians,15 senior engineers.In general,Aotian is in the leading place of paper making industry in China.

Our factory can produce mechanical pulping equipment,chemical pulping equipment,paper scrap deinking equipment, pulping and paer making sewage treatment equipment,paper-plastic of composite paper separating equipment,etc. We will provide whole services according to our clients' demand, like technical design, equipment priduction, installation and test instruction and so on.We will meet and exceed your expectations.Please contact our custom services for details.

Send Inquiry to This Supplier

You May Also Like

-

Paper Pulp Toilet Paper Machine Thruster For Virgin Pulp Production Thruster MachineUS$ 5500 - 7000MOQ: 1 Set

-

Waste Carton Board HD Cleaner High Density Cleaner In Pulping LineUS$ 1000 - 2000MOQ: 1 Set

-

Pulp Making Equipment Milling Flake 450 Double Disc Refiner MachineUS$ 8000 - 12000MOQ: 1 Set

-

Hydraulic Oxygen Air Cushion Headbox Paper Machine PartsUS$ 11000 - 100000MOQ: 1 Set

-

Low Density Cleaner Paper Machine Parts Slag Remover Pulp Industrial Low Density CleanerUS$ 5300 - 6000MOQ: 1 Set

-

Waste Paper Pulp Processing Machine Pressurized Screen Inflow Pressure ScreenUS$ 8500 - 9000MOQ: 1 Set

-

Paper Mill Horizontal Hydrapulper Machine Pulp Industry Machine Tissue HydrapulperNegotiableMOQ: 1 Set

-

Machinery for Making Straw Pulp Conveyor Paper Mill Sale Cast Iron Roller Chain Conveyor ChainUS$ 10000 - 15000MOQ: 1 Set

-

Slag Removal Pressure Screen Slotted Basket Inflow Pressure Screen for Paper Making ProcessUS$ 2500 - 3000MOQ: 1 Set

-

Rotary Drum Pulper in Waste Paper Recycling for Paper Pulp UsedUS$ 9000 - 10000MOQ: 1 Set