Megatro 500KV 5A3 J1 Light Angle Tension Transmission Tower

Megatro 500KV 5A3 J1 light angle tension transmission tower

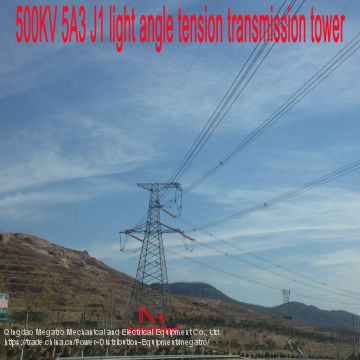

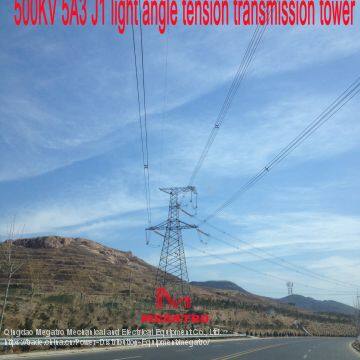

This photo refers to our 500KV 5A3 J1 light angle tension transmission tower, it is widely used in our Chinese market. Some of technical features of this tower as follow:

1 climate condition

Item | Temperature (℃) | Wind speed (m/s) | Ice thickness (mm) |

Max. temperature | 40 | 0 | 0 |

Mini. temperature | -20 | 0 | 0 |

Ice thickness | -5 | 10 | 15 |

Basic wind speed | -5 | 27 | 0 |

Installation condition | -10 | 10 | 0 |

Annual temperature | 15 | 0 | 0 |

Lightning overvoltage | 15 | 10 | 0 |

Operation overvoltage | 15 | 15 | 0 |

Hot-line work | 15 | 10 | 0 |

Ice thickness (testing) | -5 | 10 | 25 |

2 tower design data

Tower type | Nominal Height scope (mm) | Nominal Height (mm)

| Horizontal span (m) | Vertical Span (m)

| Allowed Angle º | Insulator Type

| Horizontal Span at angel condition |

5A3 J1 | 21-33 | 33 | 450 | 800 | 20~40 | / |

/ |

Conductor type: 4×LGL-400/50 | OPGW: JLB-150 | ||||||

3 Tower estimated weight and foundation force

Tower Type | Tower weight scope (kg) | Foundation force scope (KN) | |||||

Tmax | Tx | Ty | Nmax | Nx | NY | ||

5A3 J1 | 19415~25661 | 873~1033 | 108~132

| 112~127

| 1272~1461 | 145~172 | 160~181 |

MEGATRO performs in-house design activities specializing in electrical overhead transmission &telecom tower steel works, which include wind and earthquake loading, static analysis, stress analysis by finite element methods and fatigue. Our Engineering Department is boasting of highly qualified engineering who are conversant with international codes and standards. The work is carried out with extensive use of CAE/CAD via a large of computer network. The computer hardware & drafting software are liked to the CNC workshop equipment for downloading of information thereby eliminating error and saving valuable production time.

Besides, MEGATRO is one of the few manufactures who assemble a face of 500KV 5A3 J1 light angle tension transmission tower. This attention to quality may not be the cheapest process but it does insure every tower meets our high standards of quality. And it helps to reduce on-site construction cost due to mismatched assemblies. After fabrication all 500KV 5A3 J1 light angle tension transmission towers are delivered to the galvanizing facility to be Hot DIP Galvanized. Towers are processed through the facility by Caustic Cleaning, Pickling, and then Fluxing. These strict procedures insure years of maintenance free towers. All finished surfaces shall be level and free of tears, burrs, clots and impurities.

Send Inquiry to This Supplier

You May Also Like

-

MEGATRO 500KV 5C2 SZC4 Tangent Transmission TowerUS$ 920 - 960MOQ: 1 Ton

-

MEAGTRO 500KV ZB2K-1 Horizontal Type Suspension Cross-river Transmission TowerUS$ 920 - 960MOQ: 1 Ton

-

MEGATRO 500KV 5C5 SDJ Double Circuit Transmission TowerUS$ 900 - 1100MOQ: 10 Tons

-

500KV 5A2 ZBC2 Single Circuit Transmission TowerUS$ 920 - 960MOQ: 1 Ton

-

500KV 5B1 J3 Single Circuit Transmission Line Lattice Steel TowerUS$ 920 - 960MOQ: 1 Set

-

500KV 5A3 ZJB Single Circuit Light Angle Suspension TowerUS$ 920 - 960MOQ: 1 Set

-

MEGATRO 500kV 5E6 SZJC Double Circuit Cross-river Angle Transmission TowerUS$ 920 - 960MOQ: 1 Ton

-

MEGATRO 500kV 5E6 SJ1 Double Circuit Transmission TowerUS$ 920 - 960MOQ: 1 Ton

-

MEGATRO 500kV 5E7 SJ1 Double Circuit Light Angle Tension TowerUS$ 920 - 960MOQ: 1 Ton

-

MEGATRO 500KV Transmission Line 4400ZB1 Horizontal Type Suspension TowerUS$ 920 - 960MOQ: 1 Ton