metal stud and track making machinery Q2. Can you be responsible for transport?

Q1. What will you do if the machine is broken?

A4:Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freely,but you need pay the express cost yourself.If it is beyond the warranty period,we can negotiate to solve the problem,and we supply the technical support for the whole life of the equipment.

A5:Yes,please tell me the destination port or address.we have rich experience in transporting.

◊ The width can be adjusted

◊ Product width: 1000 & 1020 mm

◊ Thickness of sheet: 0.2-1.0mm

◊ Motor Power: 5.5 kw forming system

◊ Roller material: C45 steel

◊ Diameter of shaft: Upper level 95 mm

◊ Base Frame: 360 H steel welded..

◊ Oil pump station 1set.

◊ Hydraulic power: 4 kw hydraulic system.

◊ Blade Material: CR12 with heat treatment HRC60-62.

◊ Power: 440V 50Hz (as per local requirement)

◊ Roller type.

◊ Quantity: 1 pc

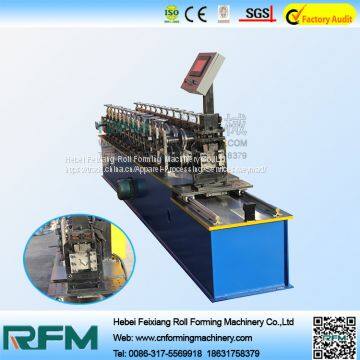

metal stud and track roll forming machinery

| Equipment operation | Automatically |

| Voltage | 380V,50/60Hz or at buyer's request |

| Thickness of material sheet | 0.3----1.5mm(normally) |

| Width of material sheet | As drawing |

| Control system | By PLC |

| Cutting method | Hydraulic cutting |

| Material of roller station | Gcr12 with hard treatment |

| Formed width | As drawing |

| Working speed | 20m/min |

| Length of finished product | set in computer, machine will cut automatically |

| Transmission type | gears |

A. Decoiler

B. Main forming machine

C. PLC Control box

D. Cutting parts

Hebei Feixiang:

a. Two decades professional cold steel forming equipments manufacturer

b. One comapny with two factory,about 30000 square meter,more than 100 employees

c. National GB/T,CE,ISO9001:2008 Certificates

d. Built business relationship with customers from more than 65 countries and areas

Certificates

Installation and training:

a.If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b.Without visiting, we will send you user manual and video to teach you to install and operate.

c.If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

Why choose FEIXIANG?

metal furring channel forming machine

*We supply all the technical support,such as engineers,drawings,and instruction manual.

*We send one or more than one engineers to client for installing and adjust all the machinery

*Supply formula guide service and staple raw material purchase.

*We could supply turnkey project to you.

*We have good reputation from our customers both at home and abroad.

Send Inquiry to This Supplier

You May Also Like

-

Color Steel Trapezoidal Panel Roll Forming MachineNegotiableMOQ: 1 Bag

-

Aluminum Panel Rolling MachineNegotiableMOQ: 1 Bag

-

312 Ridge Tile Color Steel Roll Forming MachineNegotiableMOQ: 1 Bag

-

Downspout Pipe Water Roof Roll Forming MachineNegotiableMOQ: 1 Bag

-

FX1200 Steel Sheet Panel Roll Making MachineNegotiableMOQ: 1 Bag

-

Metal Roof Color Steel Roll Forming MachineNegotiableMOQ: 1 Bag

-

Single Layer Sheet Making MachineNegotiableMOQ: 1 Bag

-

840 Metal Sheet Roll Forming MachineNegotiableMOQ: 1 Bag

-

Steel Glazed Roof Tile Roll Forming MachineNegotiableMOQ: 1 Bag

-

Metal Roofing Panel Machine Sheet Making MachineNegotiableMOQ: 1 Bag