Thermoforming—the Basic Process of Plastic Thermoforming From Shanghai YiYou

Thermoforming—the basic process of plastic thermoforming from Shanghai YiYou

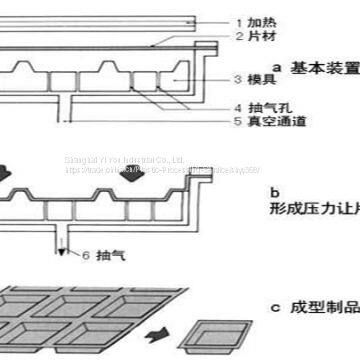

Thermoforming working principle

Plastic thermoforming equipment has manual, semi-automatic and fully automatic points. Manual equipment in all operations, such as clamping, heating, evacuation, cooling, stripping, etc. are manually adjusted to complete. Semi-automatic equipment in a variety of operations, in addition to clamping and stripping need to be done manually, the other are pre-set by the conditions and procedures automatically completed by the device. All operations in a fully automated device are performed automatically by the device.

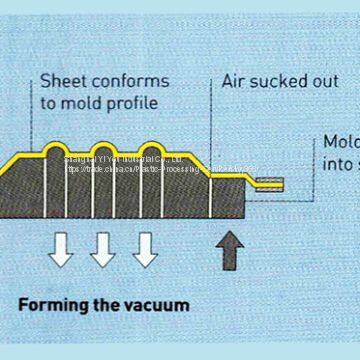

Vacuum forming

The basic process of thermoforming is: sheet clamping → heating → forming → cooling → stripping. Which is the most important and complex shape. Most of the thermoforming is carried out on a molding machine, with a large difference depending on the thermoforming method. A variety of molding machines are not to complete the above five processes, according to the actual production needs to choose. The maximum size and maximum forming depth of the clamping device are usually used as the main parameters of the thermoforming machine.

① material clamping. When the material is sandwiched and thermally molded, when the plastic sheet (sheet) cut to a certain size is used, it is necessary to hold the plate (sheet) around the sheet in order to prevent heat shrinkage and sagging.

② heating. The heating system heats the plate (sheet) at regular intervals and constant temperature to the temperature required for molding, making the material in a high elastic state and ensuring the smooth progress of the next molding process.

③ forming. The sheet (sheet) material, which is softened by heating, is molded into a desired shape by means of molds and related means.

④ cooling system. The basic molding of a plastic product with a certain temperature is cooled to below the heat distortion temperature, so that the product cooling and curing, the stripping device from the mold, the size of fixed products without deformation.

MORE<<<<<<<<<<<<<<<<<<

Send Inquiry to This Supplier

You May Also Like

-

Semi Automatic Plastic Thermoforming Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

30 Tons of Hydraulic Cutting Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

60 Tons of Hydraulic Cutting Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

80 Tons of Hydraulic Cutting Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

Automatic High-Frequency Bag Making Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

Double Head Air Pressure Pedal-Powered Hydraulic Welding Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

Manual Round Table High-Frequency Plastic Welding Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

PET Synchronization Fusing Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

Automatic Round Table Blister-Card Sealing Machine From Shanghai YiYouNegotiableMOQ: 1 Piece

-

Blister Hot-Press Sealing Machine Manufacturer From Shanghai YiYouNegotiableMOQ: 1 Piece