High Profitable Environmental Safety Waste Plastic Pyrolysis Plant to Fuel Oil

High profitable environmental safety waste plastic pyrolysis plant to fuel oil

1. Product descripition

1. automatic factory direct waste tyre processing equipment with certification of CE, ISO hine

2.Material Can Be Used For This City Waste Recycling Plant By Pyrolysis Way Getting Fuel Oil A. waste tyre B.waste rubber C.waste plastic D.waste cables E.waste oil F.Oil sand G.Other waste | |||||||||||||||||||||||||

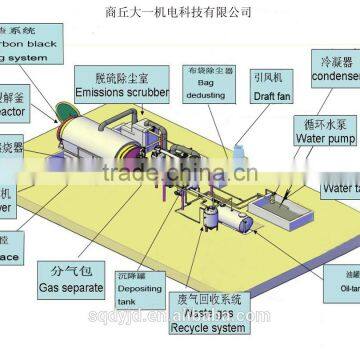

3. automatic factory direct waste tyre processing plant Work-Flow |

2. Product overview

How can our plant 100% environmental friendly?

1. Waste gas: Transferred through two safety device: water close &burning air nozzle. Fully burnt, not only eliminated pollutant

but also minimized the quantity of fuels. For smoke dust discharge, we apply series machines of patent in our company

Desulphurization and dust remover which could control the smoke dust discharge amount meet relative standards of GB-2001.

2. Waste liquid: Produced waste acidic water in the process of oil disposing (50kg process from 1 ton of oil easy to process

for small quantity). counteract the liquid by alkalescent liquid solution. After three stage of filtration, the litmusless waste

water was introduced to evaporator(use the heat of the flue of main processor as its heating resource)

3. Waste solid. The solid residua will be left after the catalyst splitting from scrap plastic, approximately composes the waste

plastic weight about 5% to 10%. Its main component is the thick black carbon. It can be the raw material of the production industry

of black carbon. Also could be mixed with the pulverized coal ash which produces for the raw material thermal power plant, also could

be the raw material of manufacture pulverized coal ash brick (one kind of environmental protection building material

How can we keep our plant absolutly safe?

A: Adopting auto-matic submerged welding-arc technology

B:All of the weldings will be detected by the ultrasonic nondestructive testing method .

C:Adopting manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.

D:Anti-explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

3. The final product

4.The work shop

5. Our clients

|

|

. |

7. About our company

8.Our service

Pre-sale service:

1.Our engineer offer project report help you analysis cost and profit,and advise customer suitable type plant and details.

2.Take customers visit running plants.

On-purchase service:

1.Once get advance payment, we will offer layout and detailed art-work drawings and detailed machine lists.

2.Help users booking ship.

After-sale service:

1. Delivery time-- It will be within 15 working days after we receive the deposit.

2. Warranty- The warranty period is 2 Years(Other suppler offer 1 year warranty), engineers available to service at any time.

3. Installation and Training-- Our Company will dispatch technician to guide installation and training for free, ensuring the operation safety. The installation period shall be

one month; otherwise, buyers will pay extra salary for the technician with the price of USD 60.00 per day.

4. 24-Hours telephone service .

Regular phone visiting to check out if there is anything we can do for you, maintenance guiding, easily worn-out parts and catalyst offering, on-site maintenance.

5.Up-date technology will inform our users and help them update plant.

6.Documents of operation manual and matters need attention will be offered to users.

Send Inquiry to This Supplier

You May Also Like

-

Large Capacity 1000L Compost Machine for Industrial Waste Composting - Stainless Steel MaterialNegotiableMOQ: 1 Set

-

Water Bath SterilizerNegotiableMOQ: 1 Set

-

Urban Garbage Sorting Plant Solid Waste Sorting Line Bulky Msw Waste Separation MachineUS$ 23500 - 68500MOQ: 1 Set

-

Aquarium Filter Media/plastic Bio Carrier for Waste Water Treatment Plant/bio Pond Filter in Anox TankUS$ 1873.70 - 2637.05MOQ: 5 Cubic Meters

-

Heavy-Duty Vertical Dewatering Machine for High-Capacity Sludge ProcessingNegotiableMOQ: 1 Set

-

Replaceable Knives Wood Chipper Digital Maximize Efficiency for BiomassNegotiableMOQ: 1 Set

-

M931 Pex Plastic Water Ice LineNegotiableMOQ: 1

-

Nickel-Iron FoamNegotiableMOQ: 10 Square Miles

-

Refuse IncineratorUS$ 5900 - 25000MOQ: 1 Piece

-

Portable Foam Wall Chemical Oil Proof 750 Gallon Flexible Pvc Spill Containment BermNegotiableMOQ: 1