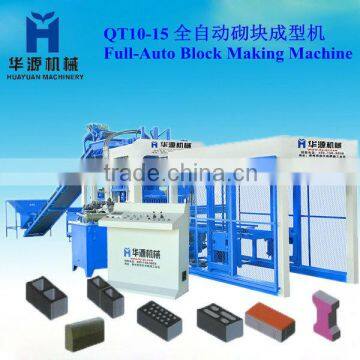

Professional Brick Manufacturing Machine QT10-15 Automatic Brick Making Machine

brick manufacturing machine QT10-15

1,Power:45.1kw

2,Cycle time:15-20s

3,Pallets size:1100*880*25mm

ISO9001&CE

Professional brick manufacturing machine QT10-15 automatic brick making machine

Contact : Mr.Banson

Skype: allence220 Mobile: 86 152 6078 7045

Concrete block machine, manufacturing machine ,concrete brick machine,concrete block making machine,hollow brick machine,hollow brick making machine. brick manufacturing machine

1.Main techical parameters of QT10-15 automatic brick manufacturing machine :

Cycle Time | 15-20 Sec | Vibration Type | hydraulic vibration |

Total Power | 45.1kw | Vibration | 105(KN) |

Motor Frequency | 50HZ | Gross Weight | 12800(kg) |

Pallet Size | 1100×880×25(mm) | Machine Size | 11500×4050×2800(mm) |

Rated Pressure | 31.5(mpa) | Stacking Machine Power | 3kw |

2,Main Technical Specifications of automatic brick manufacturing machine :

A. Intelligence PLC touch screen and pure electrical element (high automatic and easy to operate ) ;

B. Arch breaking type of rapid feeding device (better feeding multi-hole bricks with better uniformity).

C. Forming production faster and with higher compactedness ;

D. High-heat treatment special technology (to make the mould more durable and more firm) .

Raw materials :crushed stone ,sand, cement, many types of industrial waste, like, lime, fly ash, slag, coal gangue, gravel, perlite , etc.

Multiple uses. It can produce all types of standard building blocks by changing mould.

A, Multi-holes block and hollow block ;

B, Ceramsite heat preservation block;

C, Composite heat preservation concrete block.

3.Advantage of brick manufacturing machine specification:

a,Machine frame: adopt high strength steel and special welding technology

manufacturing, and stronger.

b,Oriented column: made of special steel, chrome plated , and can bear

powerful suppress and wears well.

4. Complete production line of QT10-15 brick manufacturing machine :

1. Area: Workshop area: 150-200m2, all factory area 3000m2, the bigger, the better.

2. Workers : three or four

3. Ratio of raw material:cement 8%-10% sand 30%-40% stone:50%-60%,about cement :sand : stone is1:4:5.

4. raw material consumption per day:270-280T

5. water consumption per day:3%-5% of raw material .Weight.

5.Concrete Blocks Sizes and capacity of QT10-15 brick manufacturing machine :

Brick | Sizes | Output/ mould | Output/Shift(8hours) | picture |

Blocks | 390x190x190mm | 10 | 14,400-19,200 | |

Porous bricks | 240x115x90mm | 24 | 34,560-46,080 | |

Interlocking block | 200x100x60mm | 36 | About 51,640 | |

Solid bricks | 240x115x53mm | 52 | 73,440-97,920 |

6. QT10-15 Simple automatic brick manufacturing machine production line :

7. Our factory and workshop:

8.Our world Clients for brick manufacturing machine :

9.Contact Me to know more technology infor. of brick manufacturing machine :

Send Inquiry to This Supplier

You May Also Like

-

Hot Sale Cement Interlocking Brick Making Machinery Automatic Hollow Concrete Block Making Machine China Brick Machines for Construction JobsUS$ 499 - 2256MOQ: 1 Set

-

Hollow Brick and Paver Block Making Machines Maquina BloqueraNegotiableMOQ: 1 Set

-

Pioneer High Capacity AAC Block Production LineUS$ 300,000 - 1,500,000MOQ: 1 Set

-

Hand Press Block Making Machine QTJ4-50US$ 5,000 - 10,000MOQ: 1 Set

-

Precast Wall Panel Production Machine From Shandong YuruiUS$ 10,000 - 15,000MOQ: 1 Set

-

Hollow Brick Making Machine for SaleUS$ 1,000 - 30,000MOQ: 1 Set

-

Robotic Slab/Billet Marking SystemsNegotiableMOQ: 1 Set

-

China Concrete Brick Making Machine, Cement Brick Block Making MachineUS$ 1,000 - 8,000MOQ: 1 Set

-

732 Low Price for the Small Soil Brick Making Machine 0086-15136240765US$ 19,999 - 29,999MOQ: 1 Set

-

Construction Machine Mini Type Brick Making Machine QMR2-45NegotiableMOQ: 1 Piece