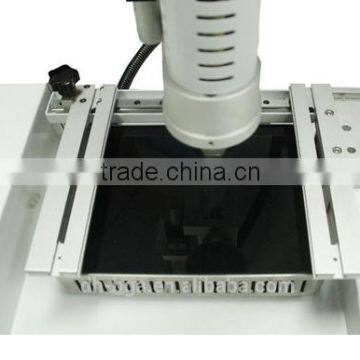

Dinghua Bga Welding Machines Rework Station for High-end Electronic Component DH-200

Dinghua bga welding machines rework station for high-end electronic component DH-200

DH-200 Specification

|

Features:

1.DH-200 special for mobile repairing, such as Samsung, iPhone, Huawei, HTC.... Mini type, lower shipping cost.

2.Top hot air heating, bottom German diode heating zone with glass guard. Top head can move up / down automatic with button. Machine movement with slides, stable and durable.

3.Embedded industrial PC, HD touch screen conversational interface, human-machine interface operation, multi-functional integrated control, human structure design, optional numbers storage, apply temperature curve freely. With multi-functions: “keep same temperature”, “instant curve analysis” and “voice warning before heating finish”. Real-time actual temperature and temperature curve setting can also be used to analyze and correct the curve if necessary.

4.high precise k-type thermocouple closed-loop control, with temperature module and intelligent control unit to enable precise temperature deviation on ±2℃. Meanwhile, external temperature measurement connector enables temperature diction and accurate analysis of real time temperature curve.

5.V-groove PCB works for rapid, convenient and accurate positioning, which can suitable for all kinds of PCB board positioning.

6.Movable universal fixture prevent pcb from damaged on fringe component, suitable for all kinds of pcb repairing.

7.With different size of magnet nozzles, easy replace and install, rotate freely 360°, any size can be custom if need. Titanium alloy material, never deformation, never rusty

8.Two heating zones can independently heat and they are multiple temperature control, which can ensure best integration of different temperature areas. Heating temperature, time, slope and cooling can all be set in touch screen conversational interface. Meanwhile PID calculation to control heating process more accurate and more stable.

9.6-8 segments temperature can be set for top heating and lower heating(up to 16 segments). 50,000 groups of temperature curves can be stored, which can number, modification and apply at any time according to different BGA. Curve analysis, setting and adjustment are also available on touch screen.

10.With Voice warning 5-10 seconds before heating finish: remind operator to pick up bga chip on time. After heating, cooling fan will work automatic, when temperature cool down to room temperature ( <45℃ ), cooling system will stop automatic to prevent the heater from aging.

11.CE certification approval. Double protection: Overheating guard + emergency stop function.

Why our machine more accurate?

Our machine use PID control, the data acquisition frequency of our machine is 10ms(which means every 10ms the PID will grab the data to correcting the temperature, but for most of BGA rework station from other companies, their PID grab frequency is 30ms, this is a big difference between 10ms and 30ms, that's why our machine is more accurate. |

Dinghua Technology profile

Should you have any question, please don't hesitate to contat us:

Skype: sinobga32

WhatsApp/Wechat:+8615768114827

Send Inquiry to This Supplier

You May Also Like

-

Dinghua DH- B1 Universal Bga Reballing Tool Kit/ Bga Reballing Kit for LaptopUS$ 850 - 1,050MOQ: 1 Set

-

Dinghua DH- B1 Bga Vga Chip Repair Machine for MotherboardsUS$ 850 - 1,050MOQ: 1 Set

-

Dinghua DH- B1 Bga Chip Desoldering and Soldering MachineUS$ 850 - 1,050MOQ: 1 Set

-

Dinghua DH- B1 Mobile Phone Bga Rework StationUS$ 850 - 1,000MOQ: 1 Piece

-

Dinghua DH-A1 Economical Bga Rework Station for Laptop/ Computer/ Mobile Phone/ Play Station Motherboard RepairUS$ 1,100 - 1,300MOQ: 1 Piece

-

Dinghua DH-A1 Computer Laptop Motherboard Chip Repairing MachineUS$ 1,100 - 1,300MOQ: 1 Piece

-

Dinghua DH-A1 TV Satellite Receiver Motherboard Soldering Desoldering StationUS$ 1,100 - 1,300MOQ: 1 Piece

-

Dinghua DH-A1 Playstation Gaming Consoles Motherboard Soldering Desoldering StationUS$ 1,100 - 1,300MOQ: 1 Piece

-

Dinghua DH-A1 Hot-selling Bga Chip Soldering Desoldering StationUS$ 1,100 - 1,300MOQ: 1 Piece

-

Dinghua DH-A1 Phone IC Soldering Desoldering StationUS$ 1,100 - 1,300MOQ: 1 Piece