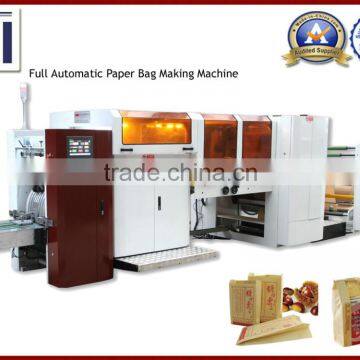

Full Automatic Machine Producing Paper Bag

Full Automatic Paper Bag Making Machine

Option: Hot Glue Equipment with Machine

Sample:

Introduction:

This machine forming the paper bag in one process from roll paper, edge folding, tube

forming, cutting, middle of bag gluing, bottom folding, bottom gluing and finishing bag.

It is an ideal machine for producing food bags like bread bags, KFC bags and McDonald’s bags.

Features:

1.This machine adopts touch screen man-machine interface, regardless of correction, trimming

can be arbitrarily set, alarm and operation state displayed on screen, easy to operate. The operation

interface, English can be switched with each other.

2. With a touch screen and man-machine interface using the German import PC programmable

control system, real-time working status display. PC system means we can solved problem

through remote control.

3. Set the original Germany servo motor control, total three Germany servo motor for puncture,

cut and bottom fold. Meantime including three Germany servo driver.

4. Printing color tracking system, using the Germany SICK color photoelectric tracking precision,

with automatic calibration function.

5.Germany SICK Photoelectric sensor limiting automatic control system, to control bottom glue

unit feed speed.

6. Taiwang Magnetic powder tension control with automatic constant tension control system,

automatic calculation of roll diameter to achieve constant tension control

7.Italy edge position control system, including correct photocell, motor and module.

8. Machine have automatic stock system, and one special batch number alarm system.

9.This machine adopts Germany original electrical system, to ensure the machine more stable,

reliable operation of the precision of the high-speed users from any menace from the "rear".

10.Safety protection design of the machine has a new humanity; full face cover design, fully

guarantee the safety and product operator environment.

Main Technical Parameters:

| Model | RZ-320 |

| Max.Making Bag Speed | 500 pcs/minute |

| Mechanical Speed | 150meter/minute;600pcs/minute |

| Finished Bag Length | 140-700mm |

| Finsihed Bag Width | 80-320mm |

| Paper Width | 100-1000mm |

| Paper Roll diameter | 200-1000mm |

| Paper core diameter | Φ75mm |

| Paper Thickness | 30-100gsm |

| The local electrical power | 3phase4wire,380V;27KW |

| Total Weight | 5000KG |

| The Machine Dimensions | 7600*1900*1900mm |

| Main Parts | from Germany |

Send Inquiry to This Supplier

You May Also Like

-

Roll Feeding Bottom Paper Bag Making Machine for FoodNegotiableMOQ: 1

-

Auto Zipper Tape Punching MachineUS$ 8 - 10MOQ: 1 Piece

-

80800C - Bag Closing MachineNegotiableMOQ: 1 Set

-

Fix A ZipperNegotiableMOQ: 3000 Sets

-

Brand Professional Sports Mitts Digital Printing Custom ProcessingNegotiableMOQ: 1 Set

-

Hardware Tools / Knife CNC Industrial Laser Cutting Machine With CabinetUS$ 3000 - 8000MOQ: 1 Set

-

Moisture-proof Transparent PET Laminating Roll Film With OEM Services For Identity CardsUS$ 4 - 5MOQ: 1 Set

-

A2 / A3 / A4 / A5 / A6 OEM Multiple Extrusion Matte Laminating Pouches Film For Cards, LicensesNegotiableMOQ: 1 Set

-

Customized Laminating Roll Transparent PET Frosted Plastic Film For ID Card, Licenses EtcNegotiableMOQ: 1 Set

-

Gold Green Rattan Belly Dance Cane , Belly Dancing AccessoriesNegotiableMOQ: 1 Set