1.Spiral chute separator is widely used to the separation for mineral particles, the size of which

ranges from 0.3 to 0.02 mm.

2.It can be suitable for dealing with different kinds of ores, such as iron ore, limonite, chromite, pyretic,rutile, monazite, tungsten ore, tin ore, tantalum ore, colombite ore as well as other nonferrous metal,

rare metal and nonmetal minerals of different proportions.

1.Reasonable structure, simple installation, small floor space, simple and easy operation.

2.Stable and clear classification, big processing capacity, high dressing and concentration ratio.

3.Damp-proof, rust-proof and corrosion resisting.

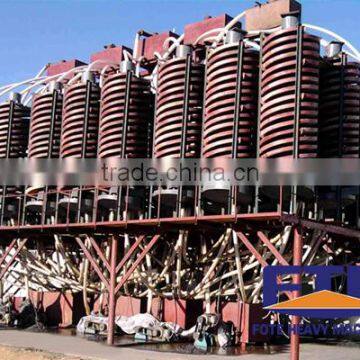

Spiral chute separator is made up of distributor ,feed chute , spiral chute, intercept chute,receiving

hopper and bracket(include cross bracket or triangle bracket)six parts etc.

Erect the spiral chute, calibrate the perpendicular line and fix it in a proper position with iron structure or wood. Send the mineral sand with the sand pump to the two feeding mouth on the top of the spiral

chute, add makeup water to adjust the density of the ore pulp, and the ore pulp will naturally rotational

flow down and produce an inertial centrifugal force in the rotary slant flow. The gravity and the

centrifugal force will separate the ores and sand according to the proportion, granularity and shape of the ore sand, and the ore concentrate will flow into the concentrate funnel and be discharged with the pipe and the tailings will flow to the tailing funnel and be discharged to the sand tank with the pipe anddrained by the sand pump to complete the whole separation process.

Henan Fote Heavy Machinery Co., Ltd covers an area of 100,000 square meters which

includes 60,000 square meters of heavy duty workshops. We have more than 200 sets

of large and medium sized metal processing equipments. The Maximum lifting capacity

is 300 tons.

1) Pre-sale service: Freely provide project designing, process designing, choosing suitable equipment for you.

2) Medium-sales service: Accompany you to complete the acceptance of the equipment,draft the construction scheme and detailed process, and complete process of export.

3) After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.

1. What guarantee do you provide?

Our products are manufactured strictly according to national and international standard, and we take a test on every machine before delivery. If products’ quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

2. How about the price?

We are the direct manfacturer,so we can offer you the lowest price than market price, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

Send Inquiry to This Supplier

You May Also Like

-

All Kinds of Mining Machinery and Wide-Body Mining Trucks, Mining Dump Truck, ExcavatorNegotiableMOQ: 1 Set

-

Gravity Separation 6-S Shaking TableNegotiableMOQ: 1 Set

-

Bimetallic Hardfacing Cladding Wearable Liners With Perfect Abrasion ResistanceUS$ 120 - 120MOQ: 1 Square Meter

-

Track Mini Excavator for Sale 2 Ton 2.5 3 Ton 5 Ton Small Rubber China Cheap Price 0.6 Ton 0.8 Ton 1 Ton 1.5 Ton 1.7 Ton 175mmNegotiableMOQ: 1

-

Essential Vibrating Bowl Feeder/vibrating FeederUS$ 9,700 - 10,000MOQ: 1 Set

-

Oil&Gas Drilling Mud Desander and DesilterNegotiableMOQ: 1 Set

-

Ceramic Particle Production Line With ISO9001:2008 CertificateUS$ 5,000 - 50,000MOQ: 1 Set

-

Hot Sell High Frequency GTS Series Drum ScreenUS$ 500 - 40,000MOQ: 1 Set

-

Hot Sale and Newly Vibrating Table Concrete for PaverUS$ 500 - 6,000MOQ: 1 Set

-

Sudan Popular Model Placer Gold Wet Grinding MachineUS$ 6,000 - 20,000MOQ: 1 Set