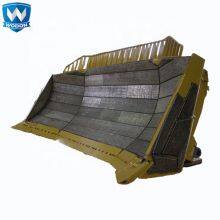

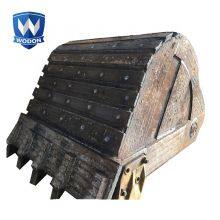

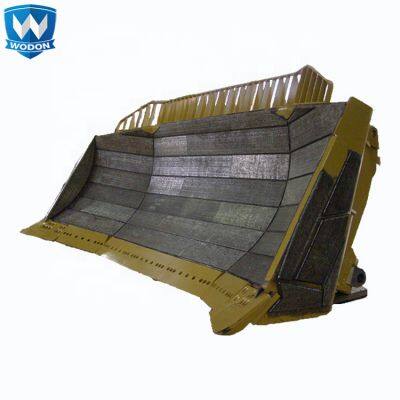

Bimetallic Hardfacing Cladding Wearable Liners With Perfect Abrasion Resistance

Bimetallic hardfacing cladding abrasion resistant wearable lining plate bucket excavator

Wodon high chromium carbide submerged arc welding wear liner plate for excavator bucket

CCO overlay abrasion resistant steel liner plate installed in the sholve grab inside

Super hardened submerged arc welding wear resistance hardfacing plate

Wodon global custom designs wear plate for optimum performance, fit and service life. Wodon can utilize many abrasion resistant materials, from our bi-metal alloy composite wear plate, and chromium carbide overlay plate, and flux cored welding wires.

Wodon specializes in total wear control. We rebuild worn-out components with high wear material that will outlast new OEM components at a fraction of the cast.

Wodon wear plate are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles.

We can customize the plates in different sizes and thickness based on customer's drawings.We can also cutting, bending and welding the wear plate into specific shapes and parts.

1. Drilling Holes

Staright holes and Countersunk holes.

2. Bolt embedded welding in the back

Embedding the pre-processed bolt in the back of wear plate.

3. Bending

Wodon wear plate can be cold formed and made into curve of cone.

4. Welding

Wodon wear plate can be welded and assembled into kinds of wear parts.

| Product Name |

Bimetallic hardfacing cladding abrasion resistant wearable lining plate bucket excavator |

| Brand | Wodon |

| Base Plate | Q235/Q345 |

| Hardfacing Plate | High chromium high carbide overlay |

| Chemical Composition | C(%): 3.0-5.0 , Cr(%): 25-40 |

| Microstructure | The carbide (Cr7C3) volume fraction on the microstructure is above 50% |

| Hardness | HRC 58-65 |

| Surface Treatment | Hardfacing, clading, coated |

| Technique | Hardfacing, open arc welding , submerged arc welding |

| Wear Resistance | High wear resistance, 30 times higher than low carbon steel and 12 times than heat treated steel. |

| Impact Resistance | Medium |

| Flatness tolerance | ±3 mm/m |

| Thickness tolerance | Uniform overlay thickness, with tolerance within 0-0.5 mm |

| Plate Size |

Open arc welding wear plate: 1400*3400mm Submerged arc welding wear plate: 1400*3400mm ; 1400*3500mm ; 2100*3500 mm; Customized. |

| Place of origin | China |

| Application | Hot mill factory, Steel mill machine part, Wear resistant factory etc. |

| Main Thickness |

3+3, 4+4, 5+5 6+4, 6+5, 6+8, 8+4, 8+10,10+4, 10+6, 10+8, 10+10, 10+20 12+6, 12+10, 12+12, 14+8, 14+10, 16+6, 16+10, 18+6, 18+10, 20+5, 20+8, 20+10, 20+20, 30+10, 40+10 |

As a ISO9001 certified factory, WODON specialize in R&D and manufacturing very good quality. Hardfacing wires, hardfacing wear plates and pipes, gas shielded welding wires and kinds of wear parts, and have mort than 10 years experience in this field.

In the United States, we have specialized laboratories to do wear tests. And in China, we have the inspection report issued by quality inspection center of Harbin welding institute of China academy of machinery science and technology.

| Wear Plate and Wear Components Packing | |

| Size | wear plate size: 1400*3000mm;1400*3500mm; 14000*3400mm; 2100*3500mm, Customized. |

| Packing | Steel pallets, Non fumigation pallets, film, Customized. |

| Delivery Time | 10- 40 days. |

Packing: We use customized size pallet to support our products and we can also make special customized steel pallet according to the customer's drawing. So that not only support our product safely but also easy to transport with.

Wodon global custom designs wear resistant plate for optimum performace, fit and service life. Wodon can utilize many abrasion resistant materials, from our bi-metal alloy composite wear plate, and chromium carbide overlay wear plate, and flux cored welding wires.

Wodon specializes in total wear control. We rebuild worn-out components with high wear material that will outlast new OEM components at a fraction of the cast.

As a ISO9001 certified factory, WODON specialize in R&D and manufacturing very good quality hardfacing wires, hardfacing wear plates and pipes, gas shielded welding wires and kinds of wear parts, and have more than 10 years experience in this field.

Wodon is committed to providing high-quality wear plate, and with good reputation. Many overseas customers willing to work with our company to establish long-term working relationship.

Wodon is the leading manufacturer of wear resistant materials in China. In China, many steelworks, cement plants, coal mine plants and so on, buying wear resistant plate, wear resistant flux cored welding wires and wear resistant part from our company. As well as established a stable relationship of long-term cooperation. Abroad, our products also sold to many countries, "made in China" is not only excellent quality but also high cost performance.

Wear Plate Processing Workshop

- We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardfacing wear plate. It is equipped with four welding guns that can work simultaneously to overcome low productivity, poor flatness and overlay falling off, easily caused by single gun.

- This is a high automation level machine. Each welding gun can operate independently and restart exactly from the point it had stopped, Simplifying the operation process. Wear plate manufactured by this equipment have many advantages like flat surface, micro and irregular cracks, and uniform hardness being very well accepted by our customers.

- And the most advantage is cost saving, so our customer could get good quality and high cost performance wear resistant plate.

Warehouse of flux cored welding wire and chromium carbid overlay wear resistant material steel plate

WODON is committed to providing high-quality wear plate, and with good reputation. Many overseas customers willing to work with our company to establish long-term working relationship.

WODON is the leading manufacturer of wear resistant materials in China. In China, many steelworks, cement plants, coal mine plants and so on, buying wear resistant plate, wear resistant flux cored welding wires and wear resistant parts from our company. As well as established a stable relationship of long-term cooperation. Abroad, our products also sold to many coutries, "made in China" is not only excellent quality but also high cost performance.

Customer visit our factory

Attend foreign exhibition

WODON wear plate and flux cored welding wires widely used for kinds of industry field: Dredging, Mining, Steelworks, Refineries, Cement, Timber, Power Generation Plants, Earthmoving, Coal Power Plant, etc.

Wodon wear plate general purpose chromium carbide overlay plate typically can delivery up to 30 times the life of low carbon steel plate. Combined with it's versatility, this is the reason why Wodon wear plate has become a great cost-reducer in the manufacturer of chromium carbide, cement, glass, port transportation, power and steel, as well as in mining, oil refining, and numerous material handling application, such as scrap and steel recycling.

The steel manufacturing industry, for example, requires wear protection for hoppers, conveyor liners quickly erode without hardfacing protection.

In mining, without hardfacing protection, critical components such as chute liners, front-end loader liners, and wear pads prematurely lose their usefulness due to the impact of silicious matter.

Refuse processing plants use overlay products hydrapulper liners and beaters, screw conveyors, conical section wear liners, baler liners, tub liners, transfer points, fan blades and liners, and ash removal systems.

Q: Are you trading company or manufacturer?

A: We are factory.

Q: How long is your delievery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provied samples? is it free or extra?

A: Yes, we could offer the wear plate and flux cored welding wires' samples for free charge.

Q: What is your terms of payment?

A: 30% T/T in advance, balance against copy of BL.

Company: Jiangsu Wodon Wear Resistant Material Co., Ltd

Send Inquiry to This Supplier

You May Also Like

-

Wear Steel Plate Liner Coal Chute Bunker ASTM Wear-Resistant Steel Custom Including Cutting Welding Bending PunchingUS$ 120 - 600MOQ: 1 Square Meter

-

Wear-resistant Lining Plate for the Inner Part of the Mining Feeding ChuteUS$ 120 - 600MOQ: 1 Square Meter

-

Chute Wear Liners Customizable Processing Services Cutting Bending WeldingUS$ 180 - 180MOQ: 1 Piece

-

Custom - Made Coated Wear Resistance Steel Plate to Meet Your Specific RequirementsUS$ 100 - 300MOQ: 1 Square Meter

-

High Quality Abrasion Resistant Bimetallic Plate Hardfacing/Overlaying Wear PlateUS$ 100 - 300MOQ: 1 Square Meter

-

Factory Price Wodon Super Wear-Resistant Steel Plate Hardfacing Alloy Chromium Carbide PlateUS$ 100 - 300MOQ: 1 Square Meter

-

Wodon Super Wear-Resistant Steel Plate: Built for Harsh ConditionsUS$ 100 - 300MOQ: 1 Square Meter

-

Chromium Carbide Overlay Wear for Chute/Hopper/Feeder/Bucket/Cone LinerUS$ 100 - 300MOQ: 1 Square Meter

-

High Chromium Carbide Overlay Plate Liner Plate Wear Resistant Steel PlateUS$ 100 - 300MOQ: 1 Square Meter

-

High Strength Wear Resistant Steel Plate Abrasion Resistant Steel Sheet Plate PriceUS$ 100 - 300MOQ: 1 Square Meter