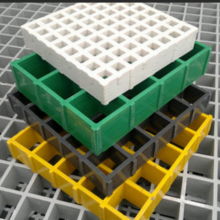

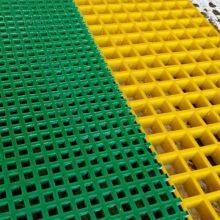

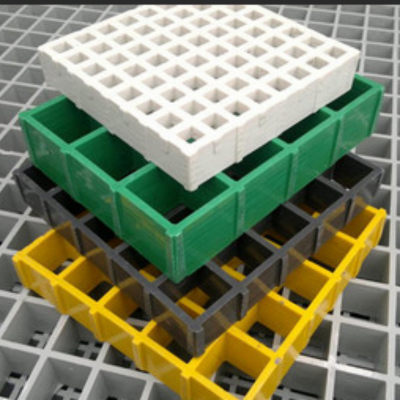

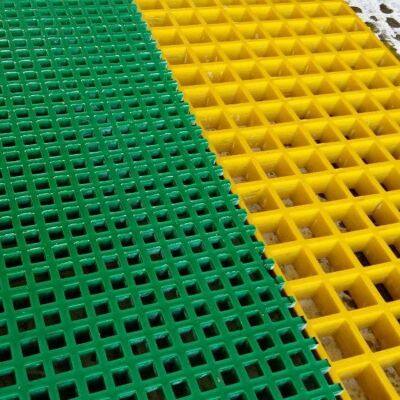

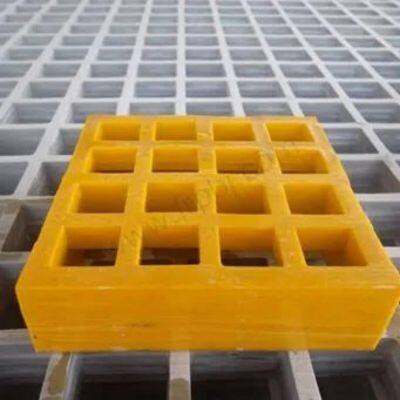

GRP Molded Grille Adopts Molding Process for Corrosion Resistance and Pressure Resistance

GRP molded grille adopts molding process for corrosion resistance and pressure resistance

GRP grid plate, plastic steel grid plate, polyurethane steel grid plate, also known as composite material grid plate, mold plastic steel grid plate, is a fiberglass product made of unsaturated polyester resin as the matrix and alkali free glass fiber as the reinforcement material through special processes. It can be used as a structural material for floors, platforms, ship decks, building walkways, etc. in corrosive environments. It has the characteristics of lightweight and high strength, corrosion resistance and flame retardancy, non-magnetic insulation, bright colors, and multiple styles to choose from. It is applied in areas prone to acid and alkali corrosion, damp heat and rust, such as power generation, electroplating, marine operations, etc. It can be used as a supporting material for anti-corrosion plates, sewage treatment, chemical, electroplating equipment and fiberglass products, such as trench covers,

overflow channels, etc. Product Features: Corrosion resistant, long service life, maintenance free. GRP molded steel grating is resistant to corrosion from various gas and liquid media such as acid, alkali, organic solvents, and salts. Unlike traditional metal gratings, it does not undergo electrochemical corrosion or rust under the action of chemical media, and does not damage the structure of the material. It does not require regular or irregular inspection and maintenance. It is also different from materials such as wood that may undergo decay, mold, and other phenomena. According to the requirements of actual usage scenarios, it is economically possible to choose to use resins such as ortho -, meta -, and vinyl based as matrix materials. Lightweight and high-strength, easy to cut and install Fiberglass grating is a composite of resin and fiberglass, with a lower density. Compared with steel grating, it has a lighter weight, which can greatly reduce the foundation support and material cost of the project. Its cutting and installation are simple, without the need for hot work or large lifting equipment, requiring only a small amount of manual labor and electric tools, greatly reducing installation costs.

Send Inquiry to This Supplier

You May Also Like

-

High-quality Molded GRP GratingsUS$ 10 - 60MOQ: 100 Square Meters

-

Fiberglass/FRP/GRP/Molded Grating With Big MeshUS$ 20 - 65MOQ: 100 Square Meters

-

High Strength Pultruded Frp Grill Fiberglass, Grp GratingUS$ 3 - 5MOQ: 200 Kilograms

-

FRP/GRP t Molding Profiles Plastic t Edge BandingNegotiableMOQ: 1000 Square Meters

-

Powerful Fiberglass Molded Grating Manufacturer GRP Grating For Equipment PlatformUS$ 30 - 60MOQ: 50 Square Meters

-

BBQ GRILL FISH HUNTING TABLE (BLOWING MOLD)US$ 35 - 37MOQ: 200 Pieces

-

New Arrival Auto Parts Grill Plastic Injection Molding & MoldUS$ 1,000 - 5,000MOQ: 1 Set

-

FRP Pultrsuion Mold Die Casting Double Grill PanUS$ 300 - 1,000MOQ: 1 Set

-

Sandwich Grill Waffle Mould Mold Panel Toaster Maker Sandwich Breakfast Sandwich Press Utensils GriddleUS$ 96 - 101MOQ: 1 Set

-

GRP Molded Grille Adopts Molding Process for Corrosion Resistance and Pressure ResistanceUS$ 32 - 33MOQ: 10 Square Meters