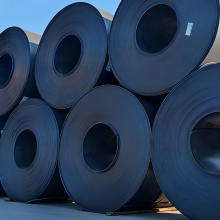

Electrical Pure Iron Hot-Rolled Coil for Magnetic Components With Low Iron Loss

Shanxi Jurun Technology Co., Ltd., headquartered in Taiyuan, Shanxi, China, specializes in manufacturing premium electrical pure iron materials tailored for demanding electromagnetic applications. Our hot-rolled coils deliver exceptional magnetic properties essential for high-efficiency components across industries.

This product stands out with its:

Superior magnetic permeability enabling precise flux control

Remarkably low iron loss characteristics reducing energy waste

Consistent material homogeneity ensuring reliable performance

Optimized hot-rolling process enhancing structural integrity

Technical specifications include:

| Property | Value Range |

| Thickness | 0.5mm - 3.0mm |

| Width | 800mm - 1250mm |

| Iron Loss (W/kg) | ≤ 4.5 (at 1.5T/50Hz) |

| Coil Weight | 3 - 10 tons |

Key advantages for manufacturers:

15-30% reduction in core losses compared to conventional electrical steels

Enhanced thermal stability during high-load operations

Improved machinability for complex component shapes

Reduced total cost of ownership through energy savings

Applications include:

Power transformers and reactors

Electric motor cores and stators

Electromagnetic actuators and sensors

Induction heating systems

Backed by Shanxi Jurun's decade-long metallurgical expertise, our production facilities implement rigorous quality control protocols. We maintain strict chemical composition management with iron purity exceeding 99.8%, ensuring batch-to-batch consistency. Customized dimensions and packaging solutions are available to meet specific application requirements.

FAQ

Q: What surface treatment is applied?

A: We provide optional anti-rust oil coating based on customer requirements.

Q: Can I get smaller coil weights?

A: Yes, we offer customized cutting services down to 1-ton coils.

Q: Do you provide material certification?

A: Mill test certificates with chemical and physical properties are standard.

Q: What's the lead time for orders?

A: Standard products ship within 15-20 days; custom orders require consultation.

Q: How does this compare to silicon steel?

A: Our pure iron offers higher saturation flux density (up to 2.15T) and better DC bias characteristics.

Q: Are samples available?

A: Yes, we provide material samples for testing upon request.

Send Inquiry to This Supplier

You May Also Like

-

Industrial Grade DT4C Electromagnetic Pure Iron Hot-Rolled Coil With Low Iron LossNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Hot-Rolled Coil DT4C With Excellent Magnetic Properties for Electrical ComponentsNegotiableMOQ: 1 Ton

-

DT4C Grade Hot-Rolled Electromagnetic Pure Iron Coil for Relays and Sensors ProductionNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Hot-Rolled Coil DT4C for Motors and Transformers With High Magnetic PermeabilityNegotiableMOQ: 1 Ton

-

Low Iron Loss Electromagnetic Pure Iron Hot-Rolled Coil DT4C for Transformer CoresNegotiableMOQ: 1 Ton

-

Hot-Rolled Pure Iron Coil DT4C Material for Electromagnetic Devices and Core ComponentsNegotiableMOQ: 1 Ton

-

Pure Iron Hot-Rolled Coil DT4C Material With Thickness 0.5-3.0mm for Industrial ApplicationsNegotiableMOQ: 1 Ton

-

High Magnetic Permeability Pure Iron Hot-Rolled Coil DT4C for Electrical Engineering UseNegotiableMOQ: 1 Ton

-

DT4C Pure Iron Hot-Rolled Coil 0.5-3.0mm Thickness for Electrical Applications in Various SizesNegotiableMOQ: 1 Ton

-

Precision Engineered DT4 Seamless Pure Iron Tube for High-Frequency Transformer CoresNegotiableMOQ: 1 Ton