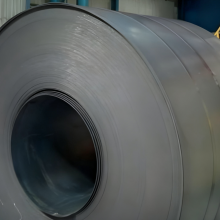

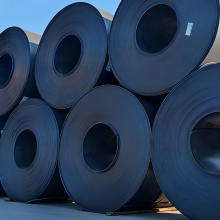

DT4C Pure Iron Hot-Rolled Coil 0.5-3.0mm Thickness for Electrical Applications in Various Sizes

Shanxi Juli Run Technology Co., Ltd. presents Electromagnetic Pure Iron Hot-Rolled Coil DT4C – engineered for superior magnetic performance in demanding electrical applications. This high-permeability material delivers exceptional magnetic flux density with minimal core losses, making it ideal for energy-efficient motors and transformers operating under variable frequencies. Manufactured through precision-controlled hot-rolling and annealing processes, our coils ensure consistent electromagnetic properties across entire batches.

Key advantages include:

Reduced hysteresis losses by up to 30% compared to conventional electrical steels

Excellent saturation induction (up to 2.15T) for compact component design

Low coercivity (

Customizable dimensions to fit specific winding and stamping requirements

Technical specifications for standard grades:

| Parameter | Value | Testing Standard |

|---|---|---|

| Core Loss (W/kg @1.5T/50Hz) | ≤4.5 | GB/T 3655 |

| Permeability (μmax) | ≥15,000 | GB/T 3656 |

| Resistivity (μΩ·m) | 0.10-0.13 | GB/T 351 |

| Coil Weight | 3-10 MT (standard) | N/A |

Our DT4C coils undergo strict quality control including:

Eddy current testing for thickness uniformity

Epstein frame validation of magnetic properties

Surface inspection for defects exceeding 0.1mm depth

Applications extend beyond standard transformers and motors to include:

High-frequency inductors for power electronics

Magnetic shielding in sensitive equipment

Relay cores requiring fast magnetization

Solenoid valves and actuators

For OEMs and electrical component manufacturers, our material enables:

15-20% weight reduction in rotating machinery

Compliance with IE4/IE5 efficiency standards

Lower operating temperatures extending device lifespan

FAQ:

Q: What surface treatment options are available?

A: Standard coils are supplied with annealed oxide surface. Epoxy coating or phosphating can be arranged upon request.

Q: Can I get customized slit widths?

A: Yes, we offer precision slitting services from 20mm to 600mm widths with ±0.1mm tolerance.

Q: How does DT4C compare to M19 silicon steel?

A: DT4C offers approximately 18% lower core losses at 50Hz and higher saturation flux density, making it preferable for high-torque applications.

Q: What is the lead time for 10MT orders?

A: Standard specifications ship within 15 days; custom-processed orders require 25-30 days production time.

Q: Do you provide material certification?

A> Full mill test certificates including chemical composition and magnetic properties accompany every shipment.

Optimize your electromagnetic devices with material that balances performance and cost efficiency. Contact our technical team at Shanxi Juli Run Technology for customized solutions and volume pricing. All products ship from our Taiyuan facility with comprehensive quality documentation.

Send Inquiry to This Supplier

You May Also Like

-

DT4C Grade Cold Rolled Pure Iron Coil for Electrical Motors and TransformersNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Hot-rolled Coil Material for Automotive and Industrial Electromagnetic PartsNegotiableMOQ: 1 Ton

-

DT4C Electromagnetic Pure Iron Coil Hot-Rolled 1000mm Width for Motor ManufacturingNegotiableMOQ: 1 Ton

-

Industrial Grade DT4C Electromagnetic Pure Iron Hot-Rolled Coil With Low Iron LossNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Hot-Rolled Coil DT4C With Excellent Magnetic Properties for Electrical ComponentsNegotiableMOQ: 1 Ton

-

DT4C Grade Hot-Rolled Electromagnetic Pure Iron Coil for Relays and Sensors ProductionNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Hot-Rolled Coil DT4C for Motors and Transformers With High Magnetic PermeabilityNegotiableMOQ: 1 Ton

-

Low Iron Loss Electromagnetic Pure Iron Hot-Rolled Coil DT4C for Transformer CoresNegotiableMOQ: 1 Ton

-

Hot-Rolled Pure Iron Coil DT4C Material for Electromagnetic Devices and Core ComponentsNegotiableMOQ: 1 Ton

-

Pure Iron Hot-Rolled Coil DT4C Material With Thickness 0.5-3.0mm for Industrial ApplicationsNegotiableMOQ: 1 Ton