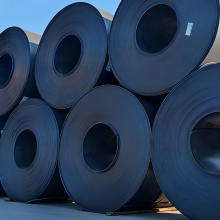

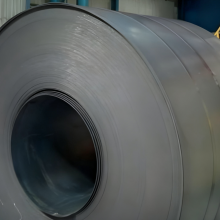

Low Iron Loss Electromagnetic Pure Iron Hot-Rolled Coil DT4C for Transformer Cores

Discover the DT4C Electromagnetic Pure Iron Hot-Rolled Coil – engineered specifically for high-efficiency transformer cores requiring minimal energy loss. This premium material delivers exceptional magnetic performance while significantly reducing operational costs through its ultra-low iron loss characteristics. Manufactured by Shanxi Juli Run Technology in China's steel production hub, our coils ensure consistent quality for critical electromagnetic applications.

With superior magnetic permeability and optimized grain orientation, DT4C coils enable transformers to operate at higher efficiencies even under demanding conditions. The hot-rolled production process guarantees uniform thickness and material homogeneity across every coil, making it ideal for precision laminations where performance consistency is non-negotiable.

Key advantages include:

- • 15-20% lower core losses compared to standard electrical steels

- • Reduced transformer noise and vibration

- • Enhanced thermal stability up to 150°C operating temperatures

- • Customizable dimensions for specific core designs

Technical specifications for standard DT4C coils:

| Parameter | Value Range |

|---|---|

| Thickness | 0.5mm - 3.0mm |

| Width | 800mm - 1200mm |

| Coil Weight | 3-10 tons (standard) |

| Iron Loss (P1.5/50) | ≤ 4.0 W/kg |

| Magnetic Induction (B50) | ≥ 1.60 T |

The material's low hysteresis loss directly translates to cooler transformer operation and extended service life. When used in power transformers, reactors, or other electromagnetic components, DT4C maintains stable magnetic properties under varying load conditions – a critical factor for grid stability equipment.

For specialized applications, we offer:

- • Surface passivation treatments for corrosion resistance

- • Precision slitting services for specific core dimensions

- • Custom annealing processes for optimized magnetic aging

Our production follows strict quality control protocols at every stage – from raw material selection to final inspection. Each coil undergoes magnetic property verification using Epstein frame testing according to GB/T 3655-2008 standards, ensuring compliance with Chinese national requirements for electrical steel.

Frequently Asked Questions:

- Q: What makes DT4C superior to standard silicon steel for transformer cores?

A: DT4C pure iron exhibits approximately 20% lower core losses and higher saturation induction (1.60T vs 1.45T), enabling more compact transformer designs with better energy efficiency. - Q: Can I get anti-rust treatment on these coils?

A: Yes, we offer optional oiling or phosphating surface treatments upon request to provide temporary corrosion protection during storage and transportation. - Q: What tolerances do you maintain for thickness?

A: Standard thickness tolerance is ±0.03mm, but tighter tolerances down to ±0.015mm can be achieved for precision applications through special rolling processes. - Q: Do you provide material certification?

A> All shipments include mill test certificates with actual magnetic properties (iron loss, permeability) and chemical composition analysis per GB/T 6983 requirements. - Q: What packaging options are available?

A: Standard packaging includes waterproof wrapping and steel strapping on wooden pallets. Custom packaging solutions are available for export requirements.

Transform your transformer efficiency with material that outperforms conventional options. Shanxi Juli Run Technology's DT4C coils deliver measurable energy savings throughout the equipment lifecycle – from reduced electricity consumption during operation to lower cooling system requirements. Contact our technical team today to discuss how our electromagnetic pure iron can optimize your specific core design requirements.

With over 15 years of specialization in precision steel products, we maintain strict quality consistency across all production batches. Our factory-direct pricing ensures you receive premium electromagnetic materials without intermediary markups. Request your samples and material data sheets now to verify the performance advantages firsthand.

Send Inquiry to This Supplier

You May Also Like

-

Cold Rolled Pure Iron Coil Material With Excellent Magnetic PropertiesNegotiableMOQ: 1 Ton

-

Electrical Pure Iron Hot-Rolled Coil for Magnetic Components With Low Iron LossNegotiableMOQ: 1 Ton

-

DT4C Hot-rolled Coil Pure Iron Cold Rolled Coil for Precision InstrumentsNegotiableMOQ: 1 Ton

-

High Permeability Pure Iron Hot-Rolled Coil for Electromagnetic ApplicationsNegotiableMOQ: 1 Ton

-

DT4C Grade Cold Rolled Pure Iron Coil for Electrical Motors and TransformersNegotiableMOQ: 1 Ton

-

Industrial Pure Iron Hot-rolled Coil Material for Automotive and Industrial Electromagnetic PartsNegotiableMOQ: 1 Ton

-

DT4C Electromagnetic Pure Iron Coil Hot-Rolled 1000mm Width for Motor ManufacturingNegotiableMOQ: 1 Ton

-

Industrial Grade DT4C Electromagnetic Pure Iron Hot-Rolled Coil With Low Iron LossNegotiableMOQ: 1 Ton

-

Electromagnetic Pure Iron Hot-Rolled Coil DT4C With Excellent Magnetic Properties for Electrical ComponentsNegotiableMOQ: 1 Ton

-

DT4C Grade Hot-Rolled Electromagnetic Pure Iron Coil for Relays and Sensors ProductionNegotiableMOQ: 1 Ton