Hydraulic Elevator Sluice Dam for Hydroelectric Power Stations

As a dedicated manufacturer since 2025, Hengshui Haogu Engineering Materials Co., Ltd. proudly produces high-quality hydraulic elevator sluice dams for hydroelectric power stations. With a robust factory spanning 3,000-5,000 square meters and annual exports valued at US$5 million to US$10 million, we ensure reliable, innovative solutions that enhance energy efficiency and water management. Serving diverse markets from North America to Southeast Asia, our products are backed by over 51-100 skilled employees and stringent certifications, providing you with durable and cost-effective infrastructure. Trust our expertise to deliver superior hydraulic systems that optimize power generation while minimizing environmental impact.

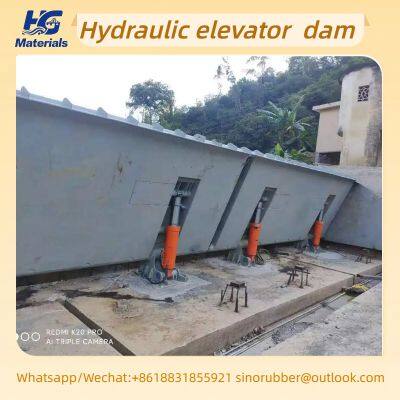

Our hydraulic elevator sluice dam features cutting-edge technology designed for seamless operation in demanding hydroelectric environments. Key characteristics include:

- Advanced Hydraulic Mechanism: Precision-engineered for smooth elevation and descent, enabling accurate water flow regulation without manual intervention, which reduces operational downtime and maintenance costs.

- Robust Construction: Built from high-strength steel or customizable alloys, it withstands high pressure, corrosion, and extreme weather, ensuring longevity in harsh conditions like floods or heavy sedimentation.

- Energy Efficiency: Optimized design reduces energy consumption during operation, lowering electricity costs for power stations and contributing to sustainable energy practices.

- Easy Installation and Integration: Pre-assembled components and modular options allow for quick setup with existing hydro systems, minimizing disruption to plant operations.

- Safety Features: Includes fail-safe mechanisms and emergency controls to prevent overflow and ensure operator safety, compliant with industry standards for risk mitigation.

Technical specifications are tailored to project needs, but standard models offer the following parameters:

| Parameter | Value | Unit |

|---|---|---|

| Max Pressure Resistance | 10-20 | MPa |

| Operating Temperature Range | -30 to 60 | °C |

| Lift Height | 5-15 | m |

| Flow Capacity | 100-500 | m³/s |

Benefits for clients include reduced operational expenses through automated controls, enhanced reliability in power output, and adaptability to various site conditions. For instance, the customizable size and configuration allow for seamless retrofitting in existing dams, boosting efficiency without major overhauls. Additionally, the hydraulic system's low maintenance requirements translate to long-term savings and uninterrupted service, making it ideal for both new installations and upgrades in hydroelectric facilities.

Backed by our QS9000, ISO9001, and ISO9004 certifications, we guarantee product excellence and adherence to global standards, reinforced by our extensive export experience to markets like Eastern Europe and Oceania. Shipping from key ports including Tianjin and Shanghai ensures timely delivery worldwide. Choose our hydraulic elevator sluice dam for its proven durability and efficiency—contact us today to discuss your project requirements and secure a solution that elevates your power station's performance.

Frequently Asked Questions (FAQ):

- What materials are used in the sluice dam? The dam is constructed from high-strength steel or optional alloys, selected for corrosion resistance and durability in aquatic environments, ensuring a long service life with minimal upkeep.

- How does the hydraulic elevation system work? It employs a hydraulic piston mechanism powered by fluid pressure, allowing smooth vertical movement for precise water level control, which can be automated for efficient operation in power generation.

- Are custom sizes available for different power stations? Yes, dimensions are fully customizable to fit specific site requirements, with options for varying lift heights and flow capacities to match your hydroelectric setup.

- What maintenance is required for the dam? Routine inspections and lubrication are recommended, but the design minimizes maintenance needs; detailed schedules are provided in the user manual upon purchase.

- Can the dam handle extreme weather conditions? Absolutely, it's engineered to withstand temperatures from -30°C to 60°C and high-pressure scenarios, with optional reinforcements available for harsher climates upon request.

- What certifications support product quality? Our dams are certified under QS9000, ISO9001, and ISO9004, ensuring compliance with international standards for safety and performance in industrial applications.

- How long does installation take? Installation time varies but typically ranges from a few days to weeks, depending on site complexity; pre-assembled components facilitate faster deployment with minimal downtime.

- What is the expected lifespan of the product? With proper maintenance, the dam can last over 20 years, thanks to robust materials and corrosion-resistant coatings that protect against wear in demanding environments.

Send Inquiry to This Supplier

You May Also Like

-

Multi-Functional Integration Hydraulic Elevator Dam Reconstruction ProjectUS$ 260 - 300MOQ: 10 Square Meters

-

Heavy-Duty Hydraulic Elevator Sluice Dam for Commercial BuildingsUS$ 260 - 300MOQ: 10 Square Meters

-

HG006 Hydraulic Elevator Dam Store Water Irrigate Landscape Flood Control Sluice Dam GateUS$ 300 - 350MOQ: 10 Square Meters

-

Hydraulic Elevator DamUS$ 300 - 350MOQ: 10 Square Meters

-

Hydraulic Steel Dam Gates and Hydraulic Self-controlled Flap Gates for River Channel and Waterway Landscape Hydraulic EngineeringUS$ 285 - 300MOQ: 10 Square Meters

-

Customized Landscape Hydraulic Dam Factory, Hydraulic Steel Dam, Hydraulic Engineering, Bottom Shaft Driven Flip Steel Dam Gate, Compression Hinge DamUS$ 285 - 300MOQ: 10 Square Meters

-

Steel Dam Hydraulic Flip-gate Sluice Gate, Steel Flap Gate Hydraulic Engineering Gate, Steel One-way Water Stop, Steel Dam Hydroelectric Steel.US$ 285 - 300MOQ: 10 Square Meters

-

Large Hydraulic Steel Dam Landscape Bottom Steel Dam Gate Flat River Water-diversion Dam Flap Hydraulic Landscape Dam Hydraulic Control GateUS$ 285 - 300MOQ: 10 Square Meters

-

Hydraulic Elevator Dam, Hydraulic Steel Dam Gate, River Channel, Reservoir, Flap Dam, Automatic Lifting, Hydraulic Steel Dam Bottom Cross-shaft DriveUS$ 285 - 300MOQ: 10 Square Meters

-

Hydraulic Elevator Dam, Hydraulic Steel Dam, Stainless Steel Dam, Hydraulic Flap Steel Dam, Supplied by ManufacturerUS$ 400 - 500MOQ: 10 Square Meters