Customized Good Price Hardware Machinery Spare Auto Part Stainless Steel Hot Die Precision Metal Forgings

Customized Good Price Hardware Machinery Spare Auto Part Stainless Steel Hot Die Precision Metal Forgings1. Product Overview

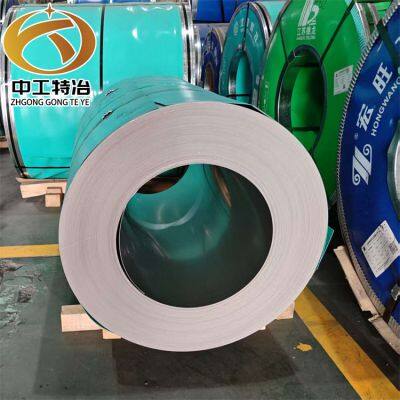

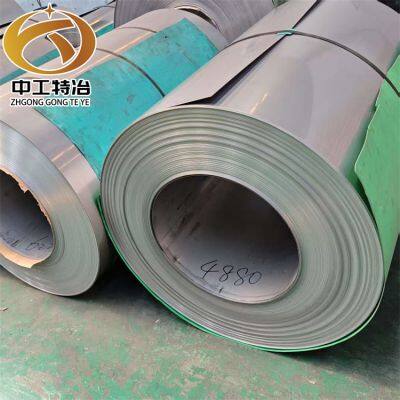

Our Customized Good Price Hardware Machinery Spare Auto Part Stainless Steel Hot Die Precision Metal Forgings are designed to meet the diverse and exacting requirements of the automotive and machinery industries. These forgings are crafted from high - quality stainless steel, which offers exceptional durability, corrosion resistance, and strength. The hot die forging process ensures that each part is precisely formed, providing a high level of dimensional accuracy and surface finish.

2. Material and Surface Treatment

Stainless Steel Material: We use top - grade stainless steel for these forgings. Stainless steel is known for its excellent mechanical properties, including high tensile strength and good ductility. It can withstand high temperatures and harsh working environments, making it ideal for use in automotive engines, transmissions, and other critical machinery components.

Bright Surface Treatment: The bright surface treatment not only enhances the aesthetic appeal of the forgings but also provides an additional layer of protection against corrosion. This treatment gives the parts a smooth and shiny finish, which is not only visually appealing but also helps in reducing friction and wear when the parts are in operation.

3. Shape and Precision

Round Shape: The round shape of these forgings is carefully designed to fit seamlessly into various automotive and machinery applications. It allows for easy installation and compatibility with other components.

Precision Forging: Our hot die precision forging process enables us to achieve extremely tight tolerances. This means that each forging is manufactured to exact specifications, ensuring a perfect fit and optimal performance. Whether it's a small, intricate part or a larger component, we can produce forgings with high precision, reducing the need for additional machining and saving both time and cost.

4. Customization Options

One of the key advantages of our product is the ability to offer customization. We understand that different customers have different needs, and we are committed to providing tailored solutions.

Design Customization: Our experienced engineering team can work closely with you to develop custom designs based on your specific requirements. Whether you need a unique shape, size, or feature, we can bring your ideas to life.

Quantity Customization: We can handle orders of various quantities, from small - scale prototypes to large - volume production runs. This flexibility allows us to serve customers of all sizes, from small businesses to large corporations.

5. Quality Assurance

We are dedicated to providing the highest quality products. Our production process is ISO9001 certified, which means that we follow strict quality control procedures at every stage of manufacturing.

In - process Inspection: We conduct regular inspections during the forging process to ensure that the parts meet our quality standards. This includes checking for dimensional accuracy, surface defects, and material integrity.

Final Testing: Before the forgings are shipped, they undergo a comprehensive final testing process. This may include non - destructive testing methods such as ultrasonic testing and magnetic particle inspection to detect any internal flaws.

6. Company Background and Services

Our company, established in 2022, has a rich history in the metal industry. We started with a metal material sales office in Beijing in 1999 and have since expanded our operations. We are a distributor and wholesaler of high - temperature alloys, Hastelloy alloys, titanium alloys, and stainless steel rods.

Product Information and Sample Supply: We provide detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality of our products.

Price and Negotiation: We offer competitive prices based on your needs. Our team is willing to negotiate prices, delivery terms, and payment methods to reach a mutually satisfactory agreement.

Order Processing: Once an order is placed, we ensure accurate and correct processing. We confirm order details such as quantity, model, and delivery time to avoid any misunderstandings.

Production Follow - up and Quality Control: We closely follow up on the production progress to ensure timely delivery. Our quality control measures ensure that the products meet your requirements and standards.

Logistics Arrangement: We take care of all transportation and logistics arrangements, including shipping, mode selection (sea freight, air freight, etc.), and customs clearance. We also track the transportation of goods to ensure they arrive smoothly at your designated location.

After - sale Service: Our customer service team is available to handle any complaints or issues you may have. We are committed to ensuring your satisfaction with our products and services.

7. Company Team

Our company has a well - structured team that plays a crucial role in our success.

Technical Team: Comprising numerous sales elites, they are proficient in the specialized knowledge of special alloys. They can quickly explain the professional knowledge of our products to customers and continuously promote product iteration and upgrading.

Market and Sales Team: Experienced marketing and sales elites accurately grasp market dynamics and effectively expand our market share.

Customer Service Team: Putting customers at the center, they provide 24 - hour uninterrupted high - quality service to ensure continuous improvement in customer satisfaction.

Innovation, Collaboration, Learning, and Responsibility: We encourage innovation within our team, emphasizing collaboration, learning, and a sense of responsibility. Our team members are encouraged to try new things, communicate across departments, and continuously learn to enhance their abilities and meet the highest standards in serving our customers.

In conclusion, our Customized Good Price Hardware Machinery Spare Auto Part Stainless Steel Hot Die Precision Metal Forgings offer a combination of high - quality materials, precision manufacturing, customization options, and excellent company services. Whether you are in the automotive or machinery industry, our forgings are an ideal choice for your needs.

Send Inquiry to This Supplier

You May Also Like

-

AISI 316 Stainless Steel Forging Components Compatible With Standard Aerospace Fasteners.NegotiableMOQ: 1 Ton

-

Durable Stainless Steel Forging Replacements for Worn Industrial Parts in Manufacturing Settings.NegotiableMOQ: 1 Ton

-

Large-scale Stainless Steel Forging Shafts Used in Bridge and Infrastructure Projects Worldwide.NegotiableMOQ: 1 Ton

-

Stainless Steel Forging Fasteners With High-temperature Resistance for Defense and Aerospace Sectors.NegotiableMOQ: 1 Ton

-

Eco-friendly Stainless Steel Forging Materials Applied in Renewable Energy Systems and Turbines.NegotiableMOQ: 1 Ton

-

Customized Good Price Hardware Machinery Spare Auto Part Stainless Steel Hot Die Precision Metal ForgingsNegotiableMOQ: 1 Ton

-

Custom Hot Die Carbon Steel/Alloy Steel/Stainless Steel Forgings in Construction Machinery/Agricultural Machinery/Vehicle/Valve/NegotiableMOQ: 1 Ton

-

High-quality Stainless Steel Forging With Precision Size Specifications for Industrial Machinery Components.NegotiableMOQ: 1 Ton

-

Stainless Steel Forging Parts Designed for Automotive Engine Assemblies and Replacement Applications.NegotiableMOQ: 1 Ton

-

Corrosion-resistant Stainless Steel Forging Offering Superior Strength in Harsh Marine Environments.NegotiableMOQ: 1 Ton