Custom Hot Die Carbon Steel/Alloy Steel/Stainless Steel Forgings in Construction Machinery/Agricultural Machinery/Vehicle/Valve/

Custom Hot Die Carbon Steel/Alloy Steel/Stainless Steel Forgings for Diverse IndustriesProduct Overview

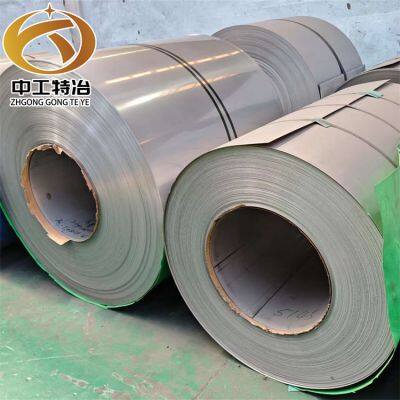

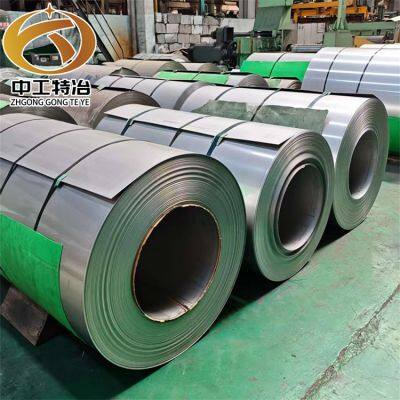

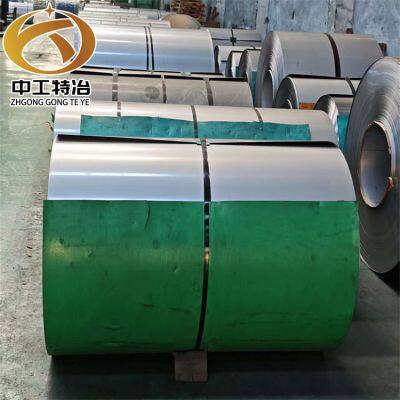

Our custom hot die forgings are crafted from high - quality carbon steel, alloy steel, and stainless steel. These forgings are specifically designed to meet the demanding requirements of various industries such as construction machinery, agricultural machinery, vehicles, valves, and more. With a bright surface treatment and a round shape, they offer both aesthetic appeal and excellent functionality.

Material AdvantagesCarbon Steel

Carbon steel forgings are known for their high strength and good ductility. They can withstand heavy loads and high - stress environments, making them ideal for construction machinery components that need to endure extreme working conditions. The carbon content in our carbon steel forgings is carefully controlled to ensure optimal performance, providing a balance between hardness and toughness.

Alloy Steel

Alloy steel forgings are engineered by adding various alloying elements such as chromium, nickel, and molybdenum. This results in enhanced mechanical properties, including increased strength, improved wear resistance, and better corrosion resistance compared to carbon steel. In agricultural machinery, where components are exposed to harsh chemicals and abrasive materials, alloy steel forgings offer long - lasting durability.

Stainless Steel

Stainless steel forgings are highly resistant to corrosion, making them suitable for applications in the vehicle and valve industries. Their anti - rust properties ensure that the forgings maintain their integrity over time, even in wet or corrosive environments. The bright surface treatment of our stainless steel forgings not only adds to their visual appeal but also provides an extra layer of protection against surface damage.

Industry - Specific ApplicationsConstruction Machinery

In construction machinery, our forgings are used in critical components such as hydraulic cylinders, connecting rods, and gears. The high - strength carbon steel and alloy steel forgings can handle the heavy - duty operations of excavators, bulldozers, and cranes. Their precise shapes and dimensions ensure a perfect fit, reducing downtime and maintenance costs.

Agricultural Machinery

For agricultural machinery, our forgings are incorporated into parts like plowshares, tiller blades, and transmission components. The alloy steel forgings' wear resistance is crucial in the abrasive soil and plant materials encountered in farming operations. This ensures that the machinery can operate efficiently throughout the planting and harvesting seasons.

Vehicles

In the vehicle industry, our stainless steel and alloy steel forgings are used in engine parts, suspension systems, and steering components. The corrosion resistance of stainless steel forgings helps to extend the lifespan of these parts, while the high - strength alloy steel forgings contribute to the overall safety and performance of the vehicle.

Valves

Valve components require forgings that can withstand high pressures and temperatures. Our carbon steel, alloy steel, and stainless steel forgings are precisely machined to ensure a tight seal and smooth operation. The bright surface treatment reduces friction, allowing for easy opening and closing of the valves.

Manufacturing Process

Our custom hot die forgings are produced through a rigorous manufacturing process. First, the raw materials are carefully selected based on the specific requirements of the customer's application. The selected steel is then heated to a high temperature in a furnace until it reaches a malleable state. Next, it is placed in a custom - designed die and forged using high - pressure equipment. This process shapes the steel into the desired form while also enhancing its internal structure, resulting in improved mechanical properties. After forging, the forgings undergo a series of heat treatments to further refine their properties, followed by precision machining to achieve the exact dimensions and surface finish.

Quality Assurance

We are committed to providing high - quality forgings. Our production is certified under ISO9001, which means that every step of the manufacturing process is strictly monitored and controlled. Our quality control team conducts comprehensive inspections at multiple stages, from raw material inspection to the final product. Non - destructive testing methods such as ultrasonic testing and magnetic particle testing are used to detect any internal defects. We also provide detailed product information and samples to our customers, allowing them to evaluate and confirm the quality of our forgings before placing an order.

Company Background

Our company, established in 2022, is a distributor and wholesaler with a rich history in the metal industry. We have overseas offices and an export share of above US$100 million. Our team consists of technical experts, market and sales professionals, and dedicated customer service representatives. The technical team is proficient in the specialized knowledge of special alloys and can quickly explain product details to customers. The market and sales team accurately grasps market dynamics to expand our market share. Our customer service team provides 24 - hour high - quality service, putting customers at the center of everything we do.

Customization and Service

We understand that different industries and customers have unique requirements. That's why we offer custom - made forgings. Our experienced engineers work closely with customers to understand their specific needs and design the most suitable forgings. We provide a comprehensive service package that includes product information and sample supply, price negotiation, order processing, production follow - up and quality control, logistics arrangement, and after - sales service. We handle customer complaints and issues promptly to ensure high customer satisfaction.

Whether you are in the construction machinery, agricultural machinery, vehicle, valve, or other industries, our custom hot die carbon steel, alloy steel, and stainless steel forgings are the ideal choice for your high - performance and reliable component needs.

Send Inquiry to This Supplier

You May Also Like

-

Durable Stainless Steel Forging Replacements for Worn Industrial Parts in Manufacturing Settings.NegotiableMOQ: 1 Ton

-

Large-scale Stainless Steel Forging Shafts Used in Bridge and Infrastructure Projects Worldwide.NegotiableMOQ: 1 Ton

-

Stainless Steel Forging Fasteners With High-temperature Resistance for Defense and Aerospace Sectors.NegotiableMOQ: 1 Ton

-

Eco-friendly Stainless Steel Forging Materials Applied in Renewable Energy Systems and Turbines.NegotiableMOQ: 1 Ton

-

Customized Good Price Hardware Machinery Spare Auto Part Stainless Steel Hot Die Precision Metal ForgingsNegotiableMOQ: 1 Ton

-

Custom Hot Die Carbon Steel/Alloy Steel/Stainless Steel Forgings in Construction Machinery/Agricultural Machinery/Vehicle/Valve/NegotiableMOQ: 1 Ton

-

High-quality Stainless Steel Forging With Precision Size Specifications for Industrial Machinery Components.NegotiableMOQ: 1 Ton

-

Stainless Steel Forging Parts Designed for Automotive Engine Assemblies and Replacement Applications.NegotiableMOQ: 1 Ton

-

Corrosion-resistant Stainless Steel Forging Offering Superior Strength in Harsh Marine Environments.NegotiableMOQ: 1 Ton

-

Stainless Steel Forging Solutions Tailored for Oil and Gas Industry Pipelines and Valves.NegotiableMOQ: 1 Ton