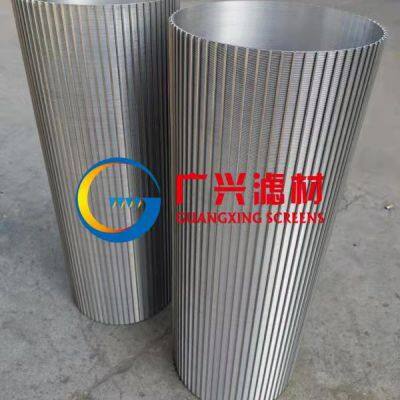

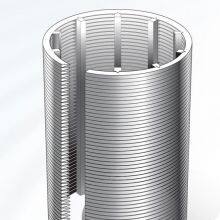

Wedge Wire Filter for Automatic Scraper Self Cleaning Filter

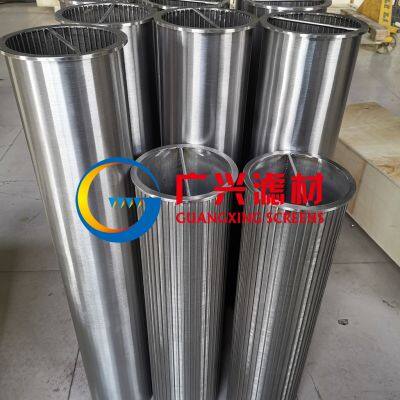

Scraper type self-cleaning filter: efficient mechanical self-cleaning filter, at the same time of filtration, automatic cleaning, automatic slag discharge, the filtration process is coherent.

The scraper type self-cleaning filter is a kind of filter which uses wedge wire filter element to directly intercept impurities in water, it can remove suspended solids and particles, reduce turbidity, purify water quality, reduce system dirt, bacteria, and algae, rust, etc., so as to purify water quality and protect the normal operation of other equipment in the system.

The water enters the self-cleaning filter body from the water inlet. Due to the intelligent (PLC, PAC) design, the system can automatically identify the degree of impurity deposition and automatically discharge the sewage to the blowdown valve signal.

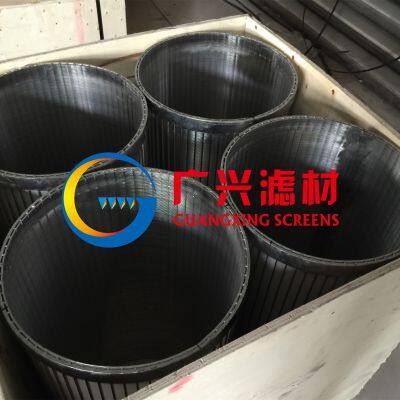

Different from the backwash type self-cleaning water filter, the scraper filter is not only used for water filtration, but also widely used for self-cleaning filtration of viscous materials such as solvents, acid-base solutions, polymers, coatings, etc., with higher efficiency, precision range of 30-3000 microns, and treatment viscosity of up to 800, It is used in water treatment, petrochemical, metallurgy, electric power, fine chemical industry, coating, ink, papermaking, food and beverage, pharmaceutical, metal processing, and other industries.

Ring scraping filter, fully automatic operation, high filtering precision, stable and reliable performance, is the benefit choice to replace the traditional manual filter or the disposable filter material filter. It can replace the traditional core filter, bag filter, basket filter, vibrating screen filter, and so on in many fields.

Filtration process

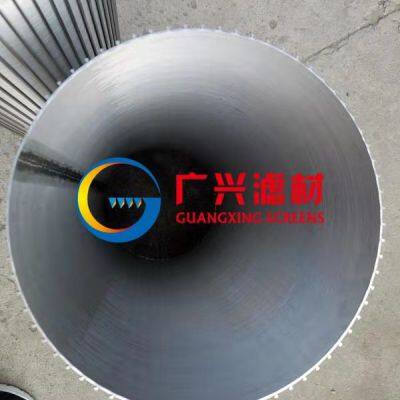

The water enters from the inlet, first through the large gap wedge wire filter to remove the impurities of larger particles, and then to the more precise wedge wire filter.

In the process of filtration, the filter element gradually accumulates the dirt and impurities in the water, forming a filtering impurity layer. As the impurity layer accumulates on the inside of the fine filter screen, a differential pressure is formed on both sides of the fine slotted filter screen.

When the pressure difference of the filter reaches the preset value, the automatic cleaning process will start. The purified water supply will continue to flow, the cleaning valve will be opened, and the water pressure in the cleaning room and the dirt absorber will drop greatly, through the pressure difference between the wedge wire screen cylinder and the suction pipe, a suction force is generated between the suction pipe and the cleaning chamber through the suction nozzle, forming a pollution absorption process.。

At the same time, the electric motor drives the suction pipe to do a spiral movement along the axial direction. The combination of axial movement and rotary movement of the suction device will completely clean the inner surface of the filter screen. The whole washing process only takes tens of seconds. The drain valve is closed at the end of the cleaning. The filter begins to prepare for the next flushing cycle.

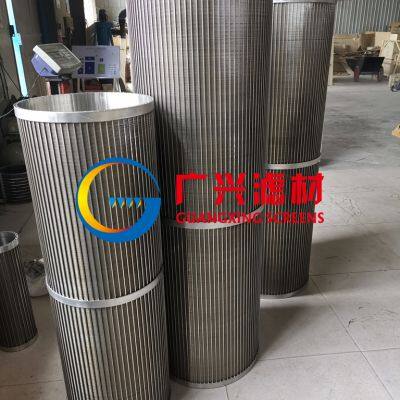

The water to be treated enters the body through the water inlet, and the impurities in the water deposit on the stainless steel Johnson screen filter, resulting in pressure difference.。

When the pressure difference reaches the set value, the electric controller sends signals to the hydraulic control valve and drive motor, causing the following actions:

The motor drives the brush to rotate to clean the filter element. At the same time, the control valve is opened for blowdown. The whole cleaning process only takes tens of seconds. When the cleaning is finished, the control valve is closed, the motor stops rotating, and the system returns to its initial state, and the next filtration process begins.

Send Inquiry to This Supplier

You May Also Like

-

Welded Wedge Wire Candle FiltersUS$ 15 - 18MOQ: 10 Meters

-

Welded Stainless Steel V Wire Wedge Wire ScreenUS$ 15 - 18MOQ: 50 Meters

-

Looped and Welded for Food Processing Wedge Wire Flat Panel ScreenUS$ 230 - 240MOQ: 10 Square Meters

-

Diatomite Filter Used Wedge Wire Screen Filter Elements With 25 Micron Slot Diatomaceous Earth Beer FilterUS$ 25MOQ: 10 Meters

-

Wedge Wire Screen FilterUS$ 5 - 6MOQ: 50 Sets

-

Sewage Treatment Technology of Paper MillUS$ 175 - 180MOQ: 1 Set

-

Stainless Steel Wire Wrapped Screen Wedge Wire Screen Casing PipeUS$ 48 - 50MOQ: 10 Meters

-

Bead Mill Screen Filter What is the Grinding Machine Filter Element?US$ 28 - 30MOQ: 5 Pieces

-

Anti-blocking Screen Self-cleaning Screen Mesh Steel Wire Mesh Vibrating Screen Stainless Steel Quarry Mining MeshUS$ 9.5 - 10MOQ: 1 Square Meter

-

Ss 304 316 Stainless Steel Flexible Zoo Wire Rope MeshNegotiableMOQ: 50 Square Meters