Saman Oil-free Vortex Air Compressor is Highly Efficient, Quiet, Oil-free, Energy-saving and Environmentally Friendly.

Oil-free Vortex Air Compressor: Advantages, Features and Applications

I. Equipment Overview

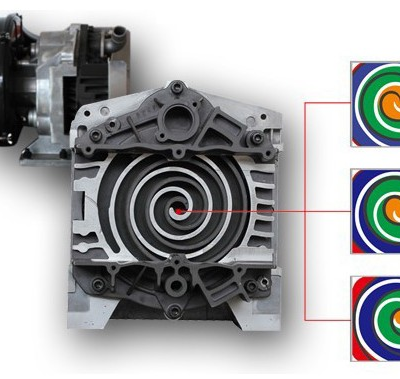

The oil-free vortex air compressor is a dry-type oil-free compression device based on the vortex compression principle. Its core structure consists of a stationary vortex disk and a moving vortex disk (the two do not touch, and the sealing effect is guaranteed through precise processing). During operation, the continuous inhalation, compression, and discharge of gas are achieved through the revolution motion of the moving vortex disk. The significant feature of this equipment is that the compression chamber contains no lubricating oil, and it can stably output oil-free compressed air that meets the ISO 8573-1 Class 0 standard (zero level). It plays an indispensable role in fields with strict air quality requirements.

II. Core Advantages

(1) Excellent Air Cleanliness: No oil pollution, meeting the needs of high-cleanliness scenarios

Zero-level oil-free certification guarantee: Since no oil is added to the compression chamber, the oil content of the output air can be controlled at an extremely low level of mg/m³, eliminating the risks of oil mist pollution and oil leakage at the source, and eliminating the need for additional oil filtration equipment, reducing equipment investment and maintenance costs.

Simplified post-treatment process and environmental protection: No installation of oil separation devices, oil filters, etc. related to oil; during operation, no oil-containing condensate is produced, greatly reducing the cost of waste liquid treatment, and also reducing the pollution pressure on the environment, in line with the modern industrial green development trend.

Wide adaptability to high-demand fields: In the medical industry (such as dental treatment, operating room air supply, ventilator air source), food and beverage industry (product packaging, filling process), pharmaceutical industry (pharmaceutical production environment), precision electronics industry (electronic component manufacturing), laboratory (experimental equipment air supply), and textile industry (textile processing), etc., fields with extremely strict air quality requirements, it can perform outstanding performance, providing reliable clean air source guarantees for production and experiments.

(2) High-efficiency Energy-saving Characteristics: Low loss and intelligent load adaptation, reducing long-term operating costs

Approximate isothermal continuous compression: The vortex compression process runs smoothly, with high volumetric efficiency, and the mechanical friction-generated loss is extremely small. Under medium-low pressure conditions (0.7–0.8 MPa), compared with the same specification piston-type air compressors, the energy-saving effect is significant, with an energy-saving rate of up to 15%–30%, and can save a large amount of electricity costs for enterprises over the long term.

Permanent magnet variable frequency and intelligent start-stop control: Standard IE3/IE4 high-efficiency motors are equipped, and some models also support variable frequency control functions, which can automatically adjust the motor speed according to actual gas demand, achieving on-demand gas supply; at the same time, it has start-stop control functions, which can eliminate power consumption during idle operation of the equipment, and the efficiency advantage is more prominent in light-load or variable-load working scenarios.

System pressure drop loss is small: Adopting a compact structure design and equipped with an efficient post-cooler, it effectively reduces pipeline resistance and pressure loss, further improving the energy efficiency of the entire compressed air system, ensuring that compressed air can be stably transported to the gas-using points at a higher pressure and flow rate.

(3) Quiet and Low-Vibration Advantage: Creating a comfortable working environment, facilitating flexible installation

Low-noise operation environment: The vortex disks operate at a lower speed, and there is no reciprocating impact motion. The overall machine operating noise is usually controlled within the range of 60–70 dB(A), and some advanced models can be as low as 58 dB(A), much lower than piston-type air compressors and ordinary screw-type air compressors. This low-noise characteristic makes it suitable for use in environments sensitive to noise, such as offices, laboratories, and medical facilities, without adversely affecting the health and work efficiency of staff.

Low-vibration operation state: The number of moving components is small and the operation is stable, no complex foundation vibration reduction facilities are required, it can be directly placed on a common floor, not only reducing the construction cost of the equipment installation, but also reducing the impact on surrounding equipment and buildings caused by vibration. (4) High reliability and low maintenance requirements: Long lifespan, few downtime, easy maintenance

Simple structure, few wear parts: The compression function is achieved solely through the revolution of the rotating disc, without the need for intake valves, exhaust valves, etc. as wear parts; compared with piston-type air compressors, the number of components is reduced by approximately 90%, significantly reducing the probability of equipment failure and improving the reliability of equipment operation.

Extremely long service life: The rotating disc has almost no wear during operation, and the service life of the main unit can reach over 100,000 hours, enabling 24-hour continuous operation, meeting the needs of large-scale and long-term production by enterprises, and reducing the frequency and cost of equipment replacement.

Economical maintenance cost: No need to regularly replace oil for compression, oil filters, oil separators, etc. related to oil; the maintenance cycle is long, typically 4,000–8,000 hours. During maintenance, only the air filter needs to be replaced regularly, and the cooling system needs to be inspected, reducing the labor cost and material cost of maintenance.

Convenient and efficient maintenance operation: Adopting a modular design, daily maintenance work does not require the use of complex professional tools, and a single person can complete the relevant operations, reducing the reliance on professional maintenance personnel and improving maintenance efficiency, reducing the risk of equipment shutdown due to inadequate maintenance.

(5) Compact structure and flexible adaptation: Saves space, simplifies installation process

Small size, light weight: Compared with piston-type air compressors of the same flow rate, the volume is reduced by approximately 40%, and the weight is reduced by approximately 15%; adopting an integrated design of the after-cooler and storage tank, the equipment's is significantly reduced, suitable for installation in limited-space factories or workplaces.

Installation process is simple and easy: No need to build a dedicated machine room; it can be installed nearby the gas consumption point according to actual gas consumption requirements, reducing the length of the compressed air transmission pipeline, reducing pressure loss and pipeline construction costs; some mobile models are equipped with casters, facilitating flexible adjustment of the equipment position according to changes in production layout.

Strong adaptability to wide operating conditions: Can operate stably within the temperature range of -40℃ to +40℃; some special models are also suitable for low-pressure environments in plateau areas, meeting the gas consumption needs in different regions and operating conditions.

III. Key technical features

Dry oil-free lubrication technology: The internal compression chamber does not use any lubricating oil; bearings use an independent lubrication system (using grease for lubrication) and are effectively isolated from the compression chamber to ensure no grease leakage into the compressed air during operation, maintaining the cleanliness of the output air.

Precise vortex processing technology: Adopting the LAP/GAP optimized design concept, using ultra-precision processing technology to manufacture the vortex disc, ensuring uniform and consistent gaps between the vortex discs, achieving efficient sealing effect and low friction loss, improving the compression efficiency and operational stability of the equipment.

Multiple protection systems: Equipped with complete overpressure protection, overcurrent protection, overheat protection, and phase loss protection functions; some high-end models also support remote monitoring and fault warning functions, capable of real-time monitoring of the equipment's operating status, promptly issuing alarms and taking protective measures when abnormal conditions occur, avoiding equipment damage and ensuring the safe and reliable operation of the equipment.

Reasonable flow and pressure range: Mainstream models have a flow range of 0.1–5 m³/min and an exhaust pressure range of 0.7–1.0 MPa, which can well meet the working scenarios of medium flow, medium low pressure, and high cleanliness requirements, providing users in different industries with suitable compressed air solutions.

IV. Applicability and Limitations Applicable scenarios

Industry sectors: Medical, food, pharmaceutical, precision electronics, laboratory, textile, printing, etc. These industries have extremely high requirements for air cleanliness and do not allow any oil contamination.

Operating conditions: Suitable for medium flow rate (≤5 m³/min), medium pressure (≤1.0 MPa), and variable load or light-load operation conditions. It can maintain high operating efficiency and stability under these conditions.

Installation environment: Suitable for places with noise sensitivity, limited space, and the need to be installed nearby at the gas supply points, such as hospital consultation rooms, laboratories, and small food processing plants. Limitations

Pressure and flow limitations: The pressure limit for a single-stage compression is approximately 1.0 MPa. For scenarios requiring high pressure (>1.0 MPa) or large flow rate (>5 m³/min) of compressed air, oil-free vortex air compressors are usually less economically viable compared to oil-free screw air compressors or centrifugal air compressors.

Initial cost and maintenance requirements: The initial purchase cost is slightly higher than that of the same specification piston-type air compressors; when the core components (such as the vortex disc) fail, maintenance requires professional skills and specialized tools, resulting in relatively higher maintenance costs and difficulty.

VII. Summary

The core value of the oil-free vortex air compressor is to output Class 0 grade oil-free air. It also has many advantages such as high efficiency and energy saving, low noise and vibration, high reliability and low maintenance, and compact structure. It can provide users with clean, stable, and economical compressed air. In applications with medium to small flow rates and high requirements for air cleanliness, the oil-free vortex air compressor is undoubtedly the ideal choice, which can effectively meet the production and experimental needs of various industries and provide strong support for the development of enterprises.

Send Inquiry to This Supplier

You May Also Like

-

Saman Specializes in Providing Refrigerated Dryers, Adsorption Dryers, and Precision Filters.NegotiableMOQ: 1 Piece

-

The Saman Screw Compressor Has Stable Performance and High Gas Output.NegotiableMOQ: 1 Piece

-

Screw Air Compressor Parts, Air Compressor Consumables, Three Filters for Screw Air CompressorNegotiableMOQ: 1 Set

-

Saman MV-10A Permanent Magnet Variable Frequency Screw Air CompressorNegotiableMOQ: 1 Piece

-

MA-10A Saman Screw-type Air CompressorNegotiableMOQ: 1 Piece

-

Saman Two-stage Permanent Magnet Variable-frequency Screw Air Compressor MUT-180A - Energy-saving and Environmentally FriendlyNegotiableMOQ: 1 Piece

-

Saman Oil-free Lubrication Screw Air Compressor GW-30ANegotiableMOQ: 1 Piece

-

Saman Permanent Magnet Variable-frequency Screw Air Compressor MV-20A is Energy-saving and Environmentally Friendly.NegotiableMOQ: 1 Piece

-

Saman MV-30A Permanent Magnet Variable Frequency Screw Air Compressor - Energy-saving and Environmentally FriendlyNegotiableMOQ: 1 Piece

-

Saman Water-lubricated Oil-free Screw Air Compressor GW20W Oil Content: 0NegotiableMOQ: 1 Piece