Cut and Retail 304 Stainless Steel Welded Pipes, Specification 159x8. 309s Stainless Steel Pipes Are Sold Starting From One Piece.

Taiyuan 304 Stainless Steel Welded Pipe, Specification 159x18, 3O9S Stainless Steel Pipe

Thin-walled stainless steel pipes are durable and have been recognized by the engineering community. Moreover, relevant parties are working on reducing the wall thickness and lowering the price to facilitate further promotion. Especially for small-diameter stainless steel pipes, the price is not high. Therefore, the reliability and price of the matching connection methods and pipe fittings are the main factors determining its development. In China, developers in Sichuan, Guangdong, Zhejiang, Jiangsu and other places have independently developed connection technologies and pipe fittings, which are pipes with great development prospects. The Ministry of Construction and relevant departments also attach great importance to this new type of pipe. According to the notice of the Technology Market Management and Promotion Center, Guokeshizi [2001] No. 71, on the promotion and application of "High-diameter-to-wall-ratio and High-precision Stainless Steel Medium and High-pressure Water Supply Pipes and Supporting Pipe Fittings and Special Technologies", the promotion and application of this technology and products of thin-walled stainless steel pipes are of great significance for improving the grade of modern buildings and improving and ensuring the water supply quality.

There are various connection methods for stainless steel pipes. Common types of pipe fittings include compression type, compression type, union type, push type, push-thread type, socket welding type, union flange connection, welding type, and derivative series connection methods combining welding with traditional connections. These connection methods have different applicable ranges according to their different principles, but most of them are easy to install, firm and reliable. The materials of the sealing rings or gaskets used for connection are mostly silicone rubber, rubber, and EPDM rubber that meet the requirements of national standards, eliminating the concerns of users.

Steps for Crimp Connection

1. Pipe cutting: Cut the pipe to the required length. When cutting the pipe, do not use excessive force to prevent the pipe from becoming out of round.

2. Deburring: After cutting the pipe, remove the burrs completely to avoid cutting the sealing ring.

3. Marking: To ensure that the steel pipe is fully inserted into the socket of the pipe fitting, it is necessary to mark and draw a line on the pipe end for the insertion length.

4. Assembly: The sealing ring should be correctly installed in the U-shaped groove of the pipe fitting. Insert the pipe into the socket of the pipe fitting and wait for crimping.

5. Crimping: During crimping, place the raised part of the pipe fitting in the concave groove of the mold, and keep the jaws perpendicular to the pipe axis.

6. Inspection: After crimping is completed, use a special gauge to check the crimping dimensions.

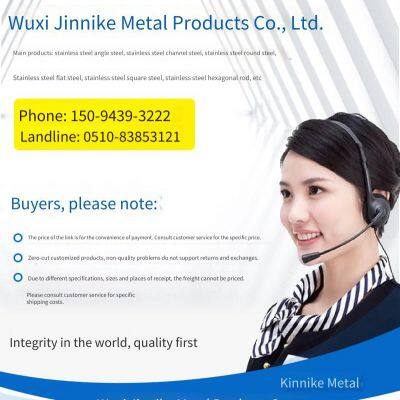

Send Inquiry to This Supplier

You May Also Like

-

Sus310s Stainless Steel Plate, Originating From Taiyuan Iron and Steel (tisco), Size: 12*1500*6000, Can be Cut, Rolled Into Circles and Welded, Customizable According to DrawingsUS$ 5076.92 - 5307.69MOQ: 1 Ton

-

Production of Tisco Medium and Heavy Plate Cutting for Retail, Materials Include 2205 (high Temperature Resistant), 310s, 2520, Laser CuttingUS$ 1.85 - 2.15MOQ: 1 Kilogram

-

Extra-wide 304 Stainless Steel Thick Plate, 3500mm Wide, Non-standard Customized, Cutting Available, Retail, Customized According to Provided DrawingsUS$ 1.85 - 2.15MOQ: 1 Kilogram

-

High-temperature-resistant Stainless Steel Boiler Tube, 310s Stainless Steel Tube, 159*12 Thick-walled Seamless Tube, Available for Cutting and RetailUS$ 6.46 - 6.77MOQ: 100 Kilograms

-

Selling 304 Stainless Steel Insulation Sheets With a Thickness of 0.3mm - 0.5mm, Sold in Lengths Starting From 10 Meters.US$ 2153.85 - 2230.77MOQ: 1 Ton

-

310s Stainless Steel Plate, Special Stainless Steel Plate for Power Plants, Corrosion-resistant and High-temperature-resistant, Cutting and Retail, Laser CuttingUS$ 553.85 - 584.62MOQ: 1 Ton

-

Sell Stainless Steel Coils From Tisco. 441, 430, and 409l Stainless Steel Plates Can All be Bent.US$ 1.85 - 2.15MOQ: 1 Kilogram

-

Large Quantity in Stock. 904l Stainless Steel Pipes in the Specification of 133*12, Available for Cutting and Retail Sales, Starting From One Kilogram.US$ 15.69 - 16MOQ: 100 Kilograms

-

Laser Cutting of 2205 Stainless Steel Medium Plate, Custom Processing According to Drawings, Welding, Coil Rounding, Cutting, Retail, and Spot SalesUS$ 2307.69 - 2353.85MOQ: 10 Tons

-

Customizable on Demand. Direct From the Manufacturer. 201 Stainless Steel Strip Tube-making Material With a Complete Range of Specifications From 0.1mm to 12mm and Fast Delivery.US$ 1292.31 - 1338.46MOQ: 1 Ton