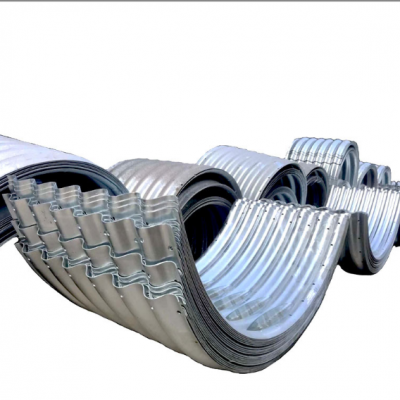

Galvanized Corrugated Metal Pipe 20mm 3/4'' Armco Mp100 Steel Pipe Flexible Corrugated Tube Large Diameter

Steel Corrugated Pipe Culvert: Professional Introduction for Engineering & B2B Promotion

Steel Corrugated Pipe Culvert (SCPC) is a high-performance, flexible underground structure engineered for water drainage and load-bearing support in civil engineering projects. Fabricated from hot-dip galvanized or polymer-coated corrugated steel plates, it serves as a critical component to channel stormwater, sewage, or river flow beneath highways, railways, urban roads, and industrial facilities, while withstanding heavy overlying loads such as traffic and earth pressure.

Core Structural Characteristics

Corrugated Design PrincipleThe culvert’s periodic ridge-and-groove corrugated profile is the key to its structural superiority. This design dramatically boosts the steel plate’s bending stiffness and compressive strength—up to 15 times higher than smooth-walled steel pipes of the same thickness. It enables the structure to work in synergy with surrounding soil, transferring loads evenly instead of resisting them directly.

Diverse ConfigurationsSCPCs are customizable to match project requirements, with three primary shapes dominating the market:

Circular: The most widely used type, ideal for highway and railway crossings, featuring uniform stress distribution and easy installation. Diameters range from 0.5m to 12m.

Elliptical: Suited for low-clearance areas where vertical space is limited, balancing drainage capacity and ground clearance.

Arch/Box: Designed for large-span, heavy-load scenarios (e.g., airport runways, mining zones), delivering exceptional load-bearing performance for shallow burial conditions.

Anti-Corrosion TreatmentsTo ensure long-term durability in harsh environments, two standard surface treatments are applied:

Hot-dip galvanization: Forms a dense zinc layer, providing 75–100 years of corrosion resistance in most soil and water conditions.

Polymer coating: For extreme corrosive environments (e.g., acidic soil, saltwater areas), this coating extends the service life by an additional 20+ years.

Key Advantages Over Traditional Concrete Culverts

| Advantage Category | Steel Corrugated Pipe Culvert | Reinforced Concrete Culvert |

|---|---|---|

| Installation Efficiency | Lightweight (easy to transport and assemble); bolted/welded connections allow on-site installation in hours/days; no curing time required | Heavy (needs crane lifting); requires 28+ days of concrete curing; long construction cycle |

| Structural Adaptability | Excellent ductility, accommodates uneven ground settlement and seismic activity without cracking | Rigid structure; prone to cracking under soil movement or earthquakes |

| Cost Performance | Lower initial cost (less raw material consumption); minimal maintenance cost | Higher material and labor costs; frequent maintenance needed for crack repairs |

| Environmental Friendliness | 100% recyclable steel material; minimal excavation reduces ecosystem disruption | High carbon emissions from concrete production; large-scale excavation damages surrounding terrain |

Typical Applications

Steel corrugated pipe culverts are versatile across multiple engineering sectors:

Transportation Engineering: Highway/railway drainage culverts, pedestrian underpasses, bridge approach structures

Water Resources Management: Stormwater drainage systems, small river crossings, flood control projects

Mining & Industrial Projects: Mine drainage tunnels, industrial wastewater culverts, storage yard load-bearing culverts

Municipal Construction: Urban sewer networks, underground utility protection, park landscape water channels

Installation & Maintenance Guidelines

Installation Process

Excavate a trench to design dimensions and prepare a stable gravel foundation to prevent uneven settlement.

Assemble culvert sections using flange bolts or field welding; ensure tight connections to avoid water leakage.

Backfill the trench with graded soil, compacting layer by layer around the culvert (critical for load transfer between the structure and soil).

Install headwalls and wing walls at both ends to guide water flow and prevent inlet/outlet erosion.

Maintenance Tips

Conduct annual inspections for corrosion, blockages, or structural deformation.

Clear debris from inlets and outlets regularly to maintain hydraulic efficiency.

Touch up damaged anti-corrosion coatings promptly to avoid rust spread.

Major structural failures are rare, thanks to the culvert’s robust flexible design.

Send Inquiry to This Supplier

You May Also Like

-

China Goods Wholesale Corrugated Steel Culvert PipeUS$ 200 - 210MOQ: 100 Meters

-

Best Price Large Diameter Corrugated Galvanized Steel Culvert Tubes ASTM Standard for Oil Pipelines Bending Cutting WeldingUS$ 200 - 210MOQ: 100 Meters

-

Customizable Culvert Pipe Oval Shaped Steel Road Cheap 36 Inch Corrugated Metal Pipe PriceUS$ 200 - 210MOQ: 100 Meters

-

Large Size 1000mm 1200mm Hot Dip Zinc Corrugated Metal Culvert Pipe Q235 Galvanized Corrugated Steel PipeUS$ 200 - 210MOQ: 100 Meters

-

Military Shelter Blast-proof Cage, Detachable Blast-proof Net, Sandbox, Five-section Blast-proof Wall, Portable Lockable SandbagUS$ 6 - 7MOQ: 100 Cases

-

Military Blast-proof Cage, Blast-proof Wall, Base Explosion-proof Shelter, Mobile Barrier, Portable Lock Sandbag, Blast-proof Net BoxUS$ 6 - 7MOQ: 100 Cases

-

Latch-type Explosion-proof Wall Welded Wire Galvanized Explosion-proof Cage Training Base Cover Explosion-proof Mesh Box Isolation Barrier CustomUS$ 6 - 7MOQ: 100 Cases

-

Military Blast-proof Cage, Blast-proof Latch, Sandbag, Blast-proof Folding Shelter, Blast Sandbox, Blast-proof Mesh BoxUS$ 6 - 7MOQ: 100 Cases

-

Custom Inflatable Rubber Dams – Dual Protection for Flood Control & Irrigation, Direct From Source FactoryUS$ 170 - 250MOQ: 20 Meters

-

Wear-Resistant & Anti-Aging Inflatable Rubber Dams – Easy Installation, First Choice for Water Conservancy ProjectsUS$ 170 - 250MOQ: 20 Meters