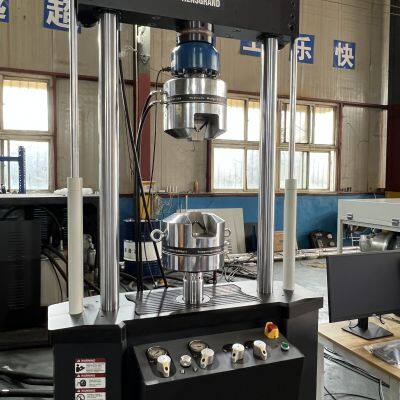

HST-P20,100hz 20kN Electro-hydraulic Servo Dynamic Static Fatigue Testing System 20kn 25kN 50kn Fatigue Testing Machine

HST-P20 Electro-hydraulicServo Dynamic static fatigue testing system

non-metallic materials and small movable member, the static mechanical properties test. It can do tensile, compression, bending,low cycle and high cycle fatigue, crack growth, fracture mechanics test under sine, triangle, square wave, trapezoidal wave,random wave, combination waveform.This Test machine is flexible, moving beam down, locking the sample holder by button operations, the use of advanced hydraulic servo drive technology loaded, high precision and high resolution dynamic load sensor magnetostrictive displacement sensor specimens force values and displacement.

Fully digital measurement and control system implementation force, displacement, deformation closed loop control, Software powerful data processing capabilities, test conditions and test results are automatically saved, displayed and printed. Fully integrated into the computer-controlled test procedure, the test machine is a research institutes, metallurgy building, defense industry, universities, machinery manufacturing, transportation and other industries ideal cost-effective test systems.

GB / T2611-2007 《Tester General technical requirements》

GB / T16826-2008 《Hydraulic servo universal testing machine》

GB 3075 《Axial fatigue testing metal》

JB / T9379-2002 《Tension and compression fatigue test machine technical conditions》

GB / T228-2010 《Metallic materials at room temperature tensile test method 》

HB5287 Axial Loading Fatigue Test Method for Metal Materials

EN10002 Tensile Test of Metallic Materials

JJG 556-2011 Axial Force Fatigue Testing Machine

HG/T 2067-1991 Technical specifications for rubber fatigue testing machine

ASTM E399-09 Metallic materials Kic standard test for linear elastic plane strain fracture toughness

ASTM E1820 2001 test standard for measuring fracture toughness

Model | Unit | HST- P20 |

Force capacity | kN | ±20 |

Relative error of test force indication | % | ±0.5 |

Testing machine accuracy | % | Static indication accuracy: ±0.5 Dynamic loading accuracy: ±1 |

Load range | % | 1%-100% |

Actuator dynamic stroke | mm | 150(±75) |

Actuator maximum amplitude | % | ±0.5%FS |

Displacement measurement accuracy | mm | 0.001 |

Deformation indication relative error | % | ±0.5% |

Frequency Range | HZ | 0.01-30 (50Hz optional) |

Dynamic test line speed | Mm/s | The maximum test speed of the test is 50 |

Force coaxiality | % | ≤8 |

Effective distance between columns | mm | 545 |

Maximum test space | mm | 800 (exclude hydraulic clamps) |

Main test waveforms | - | Sine wave, square wave, triangle wave, ramp wave, random waveform and external input waveform; can realize multiple sine waveforms with different frequency or amplitude combinations; random waveforms with user-defined parameters; user-imported custom waveforms |

Test control method | - | Load, displacement, deformation control method |

Servo pump station specifications | Flow 40L/min, 21Mpa | |

Power supply | AC 380V± 10%, 50Hz |

Scene display

Introduction to Product Structure

3.Hard chrome plated and polished

Servo actuator

*Double-out rod, the surface of the piston rod is treated with special technology, and special technology is adopted for

high-quality finish treatment, which is suitable for long-term dynamic test;

various dynamic and static test applications, minimizing the zero-point tension and compression offset load, and is especially

suitable for cyclic load applications.

to eliminate any need for awkward bending and long reaching, they feature easy-to-turn handles and clear, universally understood

labeling.

21Mpa. The oil pump motor unit is equipped with a vibration damping device (vibration damping pad is selected) to reduce vibration

and noise. Using high and low pressure switching valve group to start and stop the hydraulic system (remote control by servo

controller). Fully enclosed standard servo fuel tank. With Siemens PLC for temperature measurement and alarm; air filter device,

oil level display and alarm, self-diagnosis and abnormal shutdown and other functions;

50N-5KN Single Column Universal Testing Machine | Electronic Universal Testing Machine with 10kN Pneumatic Grips | Electronic Universal Testing Machine with Hydraulic grips |

Electronic Universal Testing Machine with Temperature Chamber | 50kN -1000kN Hydraulic Dynamic Static Fatigue Testing Machine | 100kN -2000kN Servo Hydraulic Universal Testing Machine |

FAQ:

Are your company a trading one or a factory ?

long as you tell us what kind of test you need to do and the required specification.

How to operate the machine ?

We will deliver English manual and video with the machine to you. If you still need our help, please contact us.

Does the machine can be customized according to my requirements ?

Sure, we have a strong technical team and have rich experience.Our goal is to make you satisfied.

What's the delivery term?

At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 3-10 working days after

deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and part

parts change, necessarily, our engineers may go to your place for better service.

Can you arrange the shipment for me ?

We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.

Send Inquiry to This Supplier

You May Also Like

-

HST-EFT30A 30KN,Electronic Servo Dynamic Fatigue Testing Machine 30KN Fatigue Testing MachineUS$ 196501.04 - 218334.48MOQ: 1 Set

-

HST-HFT25B 25kN Electro-hydraulic Servo Dynamic Static Fatigue Testing System 25kN Fatigue Testing MachineUS$ 342897.10 - 394681.56MOQ: 1 Set

-

HST-EFT2A 2KN Electronic Servo Dynamic Fatigue Testing Machine 2000N Fatigue Testing MachineUS$ 150874.73 - 177186.83MOQ: 1 Set

-

PWS-250 250KN COTD K1C ASTM E647 IS0 12108 CTOD Test Crack Tip Opening Displacement Test Dynamic Fatigue Testing MachineUS$ 48000 - 50000MOQ: 1 Set

-

CTOD Test Crack Tip Opening Displacement Test Fatigue Dynamic Testing MachineUS$ 48000 - 50000MOQ: 1 Set

-

Pre-crack Test and CTOD Test According to ISO 12135US$ 4800 - 50000MOQ: 1 Set

-

HST PWS-250 250KN Fracture Toughness Testing on HSLA SteelUS$ 4800 - 5000MOQ: 1 Set

-

HST 5KN High Frequency Fatigue Testing Machine Dynamic and Static Universal Fatigue TesterUS$ 167949.60 - 174947.50MOQ: 1 Set

-

HST Durability Test High Speed Fatigue Testing MachineUS$ 167949.60 - 174947.50MOQ: 1 Set

-

HST 15KN 25KN Dynamic Static Fatigue Testing Machine Universal Testing Machine Tensile Compression Fatigue Testing MachineUS$ 167949.60 - 174947.50MOQ: 1 Set