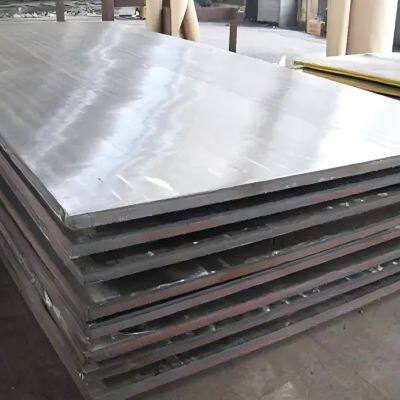

Wear Resistant Steel Plate NM450 for Construction Machinery With Superior Impact Resistance

Our NM450 wear resistant steel plate is specifically engineered for the rigorous demands of construction machinery, offering superior impact resistance to enhance durability and performance in harsh environments. Manufactured by Changsha Mingyi Machinery Equipment Co., Ltd., this steel plate helps extend equipment lifespan while reducing maintenance costs and downtime. Ideal for high-wear applications, it provides a reliable solution for industries seeking robust material performance. With its advanced composition, this plate ensures consistent quality and operational efficiency.

Key features and benefits include:

- Exceptional wear resistance – Designed to withstand abrasion from heavy loads and rough surfaces, significantly prolonging the life of machinery parts.

- Superior impact toughness – Absorbs shocks and impacts effectively, minimizing the risk of cracks or failures in dynamic construction settings.

- Customizable dimensions – Available in various thicknesses and sizes to fit specific machinery requirements, ensuring seamless integration.

- Cost-effective maintenance – Reduces the frequency of replacements and repairs, leading to lower operational expenses over time.

- Versatile applications – Suitable for a wide range of construction equipment, such as excavator buckets, bulldozer blades, and crusher liners.

Technical specifications for the NM450 steel plate include standard parameters based on industry norms. Below is a summary of typical values:

| Parameter | Typical Value |

|---|---|

| Hardness (Brinell) | Approx. 450 HB |

| Tensile Strength | 1400-1800 MPa |

| Yield Strength | ≥1200 MPa |

| Impact Toughness | ≥40 J at -20°C |

| Thickness Range | Customizable options |

These specifications ensure the plate delivers high performance in demanding conditions, with benefits like improved safety and efficiency. For instance, the combination of hardness and impact resistance allows for reliable use in high-stress areas, where standard materials might fail. Clients can expect reduced equipment downtime and enhanced productivity, as the plate's durability translates to fewer interruptions and longer service intervals. Customization options mean it can be tailored to unique project needs, providing flexibility without compromising on quality.

To maximize the advantages of this wear resistant steel plate for your construction machinery, contact Changsha Mingyi Machinery Equipment Co., Ltd. for personalized solutions and competitive pricing. Based in Changsha, Hunan, China, we offer reliable products that meet stringent industry standards. Experience the difference in durability and performance—reach out today to discuss your requirements and secure a quote for efficient, long-lasting equipment components.

Frequently Asked Questions:

-

Q: What is the primary use of NM450 steel plates?

A: They are commonly applied in construction machinery for parts like buckets and blades, where high wear and impact resistance are essential to prevent premature failure. -

Q: Can I order specific sizes for my machinery?

A: Yes, sizes and thicknesses are customizable upon request to match your equipment specifications, ensuring optimal fit and performance. -

Q: How does the impact resistance benefit construction applications?

A: Superior impact resistance absorbs shocks from heavy loads and rough terrain, reducing the likelihood of cracks and enhancing overall safety and longevity in machinery. -

Q: What is the typical delivery time for orders?

A: Delivery times vary based on order volume and customization but generally range from a few weeks, with details available upon inquiry. -

Q: Is surface treatment included for corrosion prevention?

A: While focused on wear resistance, optional surface treatments can be discussed to improve corrosion protection depending on environmental needs. -

Q: How does this plate compare to other wear-resistant grades?

A: NM450 offers a balanced profile of hardness and toughness, making it suitable for high-impact scenarios where other grades might not perform as reliably. -

Q: Are there any special handling or installation requirements?

A: Standard handling procedures apply; we provide guidelines for safe installation to ensure maximum efficiency and durability in your applications.

Send Inquiry to This Supplier

You May Also Like

-

Nm450 Abrasive Resistant Composite Wear Resistant Steel SheetNegotiableMOQ: 1 Ton

-

Nm450 Nm500 Wear Resistant Steel Sheet / Wear Resistant Steel PlateNegotiableMOQ: 1 Ton

-

Nm400 Nm450 Nm500 Nm550 Weathering Resistance Anti-Corrosion Steel Plate Q550 Q690d High Strength Wear Resistant Steel Sheet in StockNegotiableMOQ: 1 Ton

-

Nm400 Nm450 Nm500 Wear Resistant Steel Plate 6mm 8mm 12mm Thickness Hot Rolled Carbon Steel Plate Wear PlateNegotiableMOQ: 1 Ton

-

M450 Nm500 Wear Resistant Steel Sheet Nm400 Wear Steel Plate for ExcavatorNegotiableMOQ: 1 Ton

-

NM400 NM450 NM500 Wear Resistant Steel Plate Hot-Rolled Plate Cold-Rolled Finish for Ship Plate ApplicationNegotiableMOQ: 1 Ton

-

Factory Supply Black NM400 NM450 NM500 Hot Rolled Carbon Steel Sheet for ConstructionNegotiableMOQ: 1 Ton

-

Abrasive Resistant Composite Wear-resisting Plate for Cement Industry NM400 NM450 NM500 Steel SheetNegotiableMOQ: 1 Ton

-

Durable NM500 Wear Resistant Steel Plate Offering Superior Abrasion Resistance and Long Service LifeNegotiableMOQ: 1 Ton

-

NM500 High Hardness Wear Plate for Mining Truck Liners and Heavy Machinery ComponentsNegotiableMOQ: 1 Ton