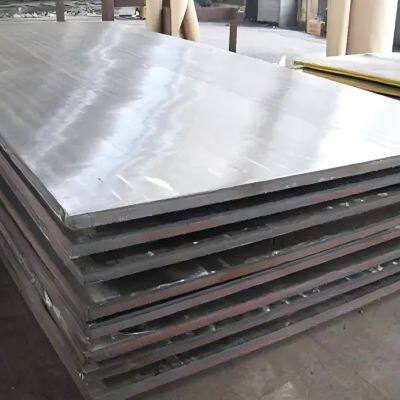

Standard Size Wear Resistant Steel Plate NM450 for Agricultural Implements and Plough Blades

Introducing our Standard Size NM450 Wear Resistant Steel Plate – engineered specifically for agricultural implements requiring extreme durability in abrasive environments. This high-performance steel plate delivers exceptional longevity for plough blades, cultivator parts, and harvesting equipment, significantly reducing replacement frequency and downtime. Manufactured by Changsha Mingyi Machinery Equipment Co., Ltd., it offers a cost-effective solution that withstands soil abrasion, rock impact, and continuous field operations while maintaining structural integrity.

With carefully controlled hardness and toughness properties, our NM450 steel ensures your agricultural equipment operates at peak efficiency throughout demanding seasons. The standardized dimensions facilitate easy integration into existing machinery designs while providing consistent performance across all production batches.

Core Technical Advantages:

- Optimized Microstructure: Heat-treated martensitic matrix with dispersed carbides for balanced wear resistance and impact absorption

- Field-Proven Durability: 3-5X longer service life compared to conventional carbon steels in tillage applications

- Reduced Operational Costs: Minimizes equipment downtime and replacement part frequency

- Adaptable Processing: Maintains consistent performance during cutting, forming, and welding operations

Technical Specifications:

| Property | Value | Testing Standard |

|---|---|---|

| Yield Strength | ≥1100 MPa | ASTM E8 |

| Tensile Strength | 1400-1650 MPa | ASTM E8 |

| Elongation at Break | ≥10% | ASTM E8 |

| Impact Energy (20°C) | ≥24 J | ASTM E23 |

Application-Specific Benefits:

- For Plough Blades: Maintains sharp cutting edge integrity against sandy and rocky soils

- For Harrow Discs: Reserves dimensional stability during high-speed soil penetration

- For Combine Components: Withstands continuous grain and stalk abrasion

- For Subsoiler Shanks: Absorbs impact from subsurface obstacles without cracking

Available in standard dimensions with thickness options from 5mm to 150mm. Custom cutting services available upon request to minimize material waste during fabrication. Surface can be supplied with mill scale or shot blasted finish depending on your painting/preparation requirements.

Transform your agricultural equipment performance with steel plates that endure extreme field conditions while maintaining cost-efficiency. Contact Changsha Mingyi Machinery for technical consultation and volume pricing options tailored to your farming equipment manufacturing needs. Our team provides comprehensive material support from prototype development to bulk production delivery.

Frequently Asked Questions

Q: What is the maximum working temperature for NM450 in field applications?

A: NM450 maintains its properties up to 250°C continuously, making it suitable for all-season farming operations.

Q: Can this plate be welded to standard structural steel?

A: Yes, using low-hydrogen electrodes and preheating (150-200°C) when thickness exceeds 20mm.

Q: What surface protection is recommended for corrosive environments?

A: While NM450 has some corrosion resistance, we recommend supplementary coatings like epoxy paints or galvanizing.

Q: How does NM450 compare to AR400 steel?

A: NM450 offers approximately 15% higher hardness and better wear resistance in high-abrasion applications.

Q: What tolerances are maintained for thickness?

A: Standard tolerance is ±0.2mm for plates under 20mm thickness, ±0.3mm for thicker plates.

Q: Can you supply pre-formed components?

A: Yes, we offer additional processing services including bending and forming upon request.

Q: What packaging options are available?

A: Standard packaging includes waterproof wrapping with steel strapping; wooden crates for export available.

Q: How does chemical composition affect wear performance?

A: Our optimized alloy design balances chromium, carbon, and boron content to maximize carbide formation without compromising toughness.

Send Inquiry to This Supplier

You May Also Like

-

Nm450 Nm500 Wear Resistant Steel Sheet / Wear Resistant Steel PlateNegotiableMOQ: 1 Ton

-

Nm400 Nm450 Nm500 Nm550 Weathering Resistance Anti-Corrosion Steel Plate Q550 Q690d High Strength Wear Resistant Steel Sheet in StockNegotiableMOQ: 1 Ton

-

Nm400 Nm450 Nm500 Wear Resistant Steel Plate 6mm 8mm 12mm Thickness Hot Rolled Carbon Steel Plate Wear PlateNegotiableMOQ: 1 Ton

-

M450 Nm500 Wear Resistant Steel Sheet Nm400 Wear Steel Plate for ExcavatorNegotiableMOQ: 1 Ton

-

NM400 NM450 NM500 Wear Resistant Steel Plate Hot-Rolled Plate Cold-Rolled Finish for Ship Plate ApplicationNegotiableMOQ: 1 Ton

-

Factory Supply Black NM400 NM450 NM500 Hot Rolled Carbon Steel Sheet for ConstructionNegotiableMOQ: 1 Ton

-

Abrasive Resistant Composite Wear-resisting Plate for Cement Industry NM400 NM450 NM500 Steel SheetNegotiableMOQ: 1 Ton

-

Durable NM500 Wear Resistant Steel Plate Offering Superior Abrasion Resistance and Long Service LifeNegotiableMOQ: 1 Ton

-

NM500 High Hardness Wear Plate for Mining Truck Liners and Heavy Machinery ComponentsNegotiableMOQ: 1 Ton

-

High-Quality NM450 Wear Resistant Steel Plate in 10-50mm Thickness for Heavy-Duty Industrial ApplicationsNegotiableMOQ: 1 Ton