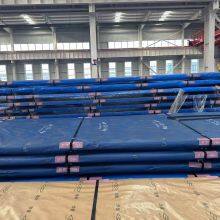

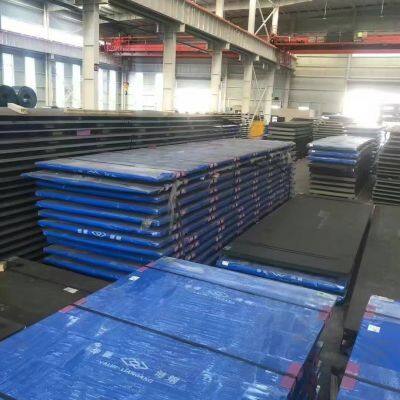

Nm450 Abrasive Resistant Composite Wear Resistant Steel Sheet

Product Overview

The Nm450 Abrasive Resistant Composite Wear Resistant Steel Sheet is a remarkable product engineered to meet the most demanding industrial wear - resistance requirements. This steel sheet is a game - changer in various sectors where abrasion and wear are constant challenges.

Material and Composition

The Nm450 steel sheet is crafted from a high - quality alloy composition. It combines elements that are carefully selected to enhance its wear - resistant properties. The base material provides a strong and stable foundation, while the composite elements are precisely integrated to form a protective layer on the surface. This layer acts as a shield against abrasive forces, ensuring long - term durability. The unique combination of metals in the alloy also contributes to its excellent mechanical properties, such as high tensile strength and good toughness.

Wear - Resistance Features

One of the most outstanding features of the Nm450 steel sheet is its exceptional wear resistance. It can withstand severe abrasion from various sources, including hard particles, sliding friction, and impact. In applications where materials are constantly in contact with rough surfaces or abrasive substances, this steel sheet maintains its integrity for an extended period. For example, in mining operations where rocks and minerals are being processed, the Nm450 steel sheet can be used to line chutes, hoppers, and conveyor belts. It reduces the frequency of replacements, thereby saving both time and money.

Applications

The Nm450 Abrasive Resistant Composite Wear Resistant Steel Sheet has a wide range of applications across multiple industries:

- Mining Industry: As mentioned earlier, it is used in equipment like chutes, hoppers, and conveyor belts. It can also be used in crushers and screens to protect against the wear caused by the continuous flow of rocks and ores.

- Construction Industry: In construction machinery, such as bulldozers and excavators, the steel sheet can be used to protect critical components from wear. It can be applied to the blades of earth - moving equipment, ensuring that they remain sharp and effective for longer periods.

- Manufacturing Industry: For manufacturing processes that involve the handling of abrasive materials, like metal stamping and forging, the Nm450 steel sheet can be used as a die or mold lining. This helps to improve the quality of the manufactured products and reduces the need for frequent die replacements.

- Transportation Industry: In the shipping and logistics sector, it can be used as container plates. The steel sheet's wear - resistant properties protect the containers from damage during loading, unloading, and transportation.

Physical and Mechanical Properties

- Hardness: The Nm450 steel sheet has a high hardness level, which is a key factor in its wear - resistance. This hardness allows it to resist deformation and abrasion under high - pressure conditions.

- Toughness: Despite its high hardness, the steel sheet also exhibits good toughness. This means that it can absorb energy during impact without cracking or breaking. It is able to withstand sudden shocks and vibrations, making it suitable for use in dynamic applications.

- Dimensional Stability: The steel sheet maintains its shape and dimensions even under extreme conditions. This ensures that it can be accurately installed and used in various equipment and structures.

Quality Assurance

The Nm450 Abrasive Resistant Composite Wear Resistant Steel Sheet is produced under strict quality control measures. Each sheet undergoes a series of tests, including hardness testing, wear - resistance testing, and chemical composition analysis. Only products that meet the highest quality standards are released into the market. This commitment to quality gives customers the confidence that they are getting a reliable and long - lasting product.

Installation and Maintenance

Installing the Nm450 steel sheet is relatively straightforward. It can be cut, welded, and formed according to the specific requirements of the application. However, it is recommended that installation be carried out by trained professionals to ensure proper fit and performance. Maintenance of the steel sheet is minimal. Regular inspections can help to detect any signs of wear or damage early on. In case of minor damage, simple repairs can be carried out to extend the service life of the sheet.

In conclusion, the Nm450 Abrasive Resistant Composite Wear Resistant Steel Sheet is a top - notch product that offers excellent wear - resistance, a wide range of applications, and reliable performance. It is an ideal choice for industries looking to improve the durability and efficiency of their equipment and structures.

Send Inquiry to This Supplier

You May Also Like

-

Factory Supply Black NM400 NM450 NM500 Hot Rolled Carbon Steel Sheet for ConstructionNegotiableMOQ: 1 Ton

-

Abrasive Resistant Composite Wear-resisting Plate for Cement Industry NM400 NM450 NM500 Steel SheetNegotiableMOQ: 1 Ton

-

Durable NM500 Wear Resistant Steel Plate Offering Superior Abrasion Resistance and Long Service LifeNegotiableMOQ: 1 Ton

-

NM500 High Hardness Wear Plate for Mining Truck Liners and Heavy Machinery ComponentsNegotiableMOQ: 1 Ton

-

High-Quality NM450 Wear Resistant Steel Plate in 10-50mm Thickness for Heavy-Duty Industrial ApplicationsNegotiableMOQ: 1 Ton

-

High-Performance Abrasion Resistant Steel Plate NM500/NM450/NM400 for Heavy-Duty ApplicationsNegotiableMOQ: 1 Ton

-

20-60mm Thick Wear Resistant Steel Plate NM500 Ideal for Crusher Liners and Conveyor SystemsNegotiableMOQ: 1 Ton

-

Premium Wear Resistant Steel Plate for Mining Equipment and Excavator Buckets in Tough EnvironmentsNegotiableMOQ: 1 Ton

-

NM450 NM400 NM500 Wear-Resistant Steel Plate With High Hardness and Impact ToughnessNegotiableMOQ: 1 Ton

-

Wear Resistant Steel Plate for Bulldozer Blades and Loader Buckets in Harsh Mining ConditionsNegotiableMOQ: 1 Ton